Biological agent for processing glutamic acid fermentation waste water

A technology of biological preparations and fermented wastewater, applied in multi-stage water/sewage treatment, food industry wastewater treatment, biological water/sewage treatment, etc., to achieve the effects of solving environmental pollution, improving animal disease resistance, and promoting animal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Get the glutamic acid fermentation liquid of Fufeng workshop, adopt the following steps:

[0046] (1) The glutamic acid fermentation broth is separated from the cell protein by a high-speed disc separator, and the speed of the high-speed disc separator is 4000-5000r / min to collect the sterilization liquid and precipitate the cell protein;

[0047] (2) Add appropriate amount of warm water to the bacterial protein prepared in step (1) and mix thoroughly, adjust the solid content to 15%, put it into the fermentation device, adjust the pH to 6.0-7.0 with lime milk, add 1 / 10 (V / V, the volume is After adding water and mixing thoroughly, the 1 / 10) compound seed liquid of bacterial protein aqueous solution is stirred evenly, and the temperature is controlled at 32-34°C. During the cultivation process, intermittent ventilation and slow stirring are cultivated for 24 hours to obtain mature fermented liquid probiotics;

[0048] The compound seed solution is prepared by Saccharomyc...

Embodiment 2

[0065] Embodiment 2: the effect test of the probiotic agent prepared in embodiment 1:

[0066] Duroc

[0067] The control group drank tap water; the test group drank 1% probiotic aqueous solution (weight ratio), with an average initial weight of 24.2 kg,

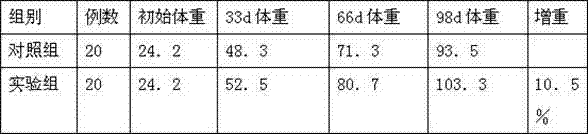

[0068] The experimental group and the control group used 20 pigs each, randomly divided into groups, and fed under the same conditions for 98 days. The growth conditions are shown in Table 1:

[0069] Table 1: Comparison of weight gain in pigs with probiotics

[0070]

[0071] The data in Table 1 show that the growth ability of the pigs in the experimental group is significantly higher than that in the control group. During the breeding period, the occurrence of diarrhea, constipation and other gastrointestinal diseases in the experimental group is significantly reduced, and the odor of feces is also significantly reduced. The number of mosquitoes and flies is also less than that of the control group, and the economic be...

Embodiment 3

[0073] Embodiment 3 Treatment example of waste water effect

[0074] Get Fufeng production workshop, extract waste water from glutamic acid, enter the sewage treatment system according to the method of embodiment 1, and use the 50L bucket as the test equipment with stirring, get 30L respectively, add in two buckets, adjust the pH to be 7.0, The water temperature was 20°C, and the data of COD, ammonia nitrogen and total nitrogen were measured by sampling; no biological agent was added to the control group, and the biological agent in Example 1 was added to the experimental group, and 20 grams of biological agent was added per cubic meter of bottom material each time, and added every day Once, after one week of continuous dosing, samples were taken to measure COD, ammonia nitrogen, and total nitrogen data. The treated wastewater fully met the discharge standard. The specific data is shown in Table 2:

[0075] Table 2

[0076] group COD a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com