Preparation method for high-quality recycled concrete aggregates

A technology of recycled concrete and recycled aggregate, applied in the field of preparation of high-quality recycled aggregate, can solve the problems of unstable indicators of recycled aggregate, affecting concrete strength, shrinkage, creep and durability, etc., to improve the peeling rate of mortar , saving land occupation, obvious environmental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] like Figure 9 Shown, the preparation method of high-quality recycled concrete aggregate of the present invention comprises the following steps:

[0040] 1. Sorting, using manual sorting to remove wood, paper, metal, and plastic materials from construction waste;

[0041] 2. Hammering, the purpose of hammering is to break the waste concrete into small pieces;

[0042] 3. For primary crushing, the waste concrete blocks after hammering are crushed with a suitable jaw crusher according to the particle size range of recycled aggregates. The output of aggregates with a particle size of 5-40mm after crushing is controlled at 80-90%. ;

[0043] 4. First-level screening, use a lifting sieve with a sieve hole of 5mm to screen the waste concrete aggregate after the first-level crushing;

[0044] 5. Grinding. Send the sieved aggregate > 5mm into the rod mill. According to the grindability of the aggregate and the amount of feed, put it into a steel rod with a suitable grade, gr...

Embodiment 1

[0050] Collect the 150×150×150mm cubic waste concrete test blocks after the strength test in the laboratory, the strength grade is C30, and the primary aggregate contains more pebbles and some crushed stones. Processed according to the steps of the method, the quality of the recycled aggregate obtained is as follows:

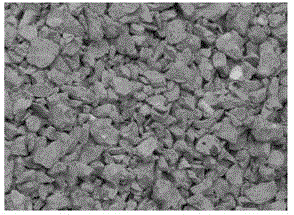

[0051] (1) figure 1 It is the appearance image of the test block of this strength level after the primary crushing by the PE300×500 jaw crusher. The particle size ranges from 5 to 40mm, and most of them are flat and long.

[0052] (2) figure 2 It is the appearance of coarse aggregate after being processed by a rod mill with a specification of 500×500×500mm (the combination of steel rods is 3 pieces of Φ50×150mm, 5 pieces of Φ40×150mm, and 5 pieces of Φ30×150mm) for 10 minutes. The grain shape is good, and the pebble surface The degree of mortar shedding is better.

Embodiment 2

[0054] Collect the 150×150×150mm cubic waste concrete test blocks after the strength test in the laboratory, the strength grade is C40, and the primary aggregate is basically crushed stone. Processed according to the steps of the method, the quality of the recycled aggregate obtained is as follows:

[0055] (1) image 3 It is the appearance image of the test block of this strength level after primary crushing by PE300×500 jaw crusher. The particle size ranges from 5 to 40 mm, and most of them are flat and long.

[0056] (2) Figure 4 It is the appearance of coarse aggregate after being processed by a rod mill with a specification of 500×500×500mm (the combination of steel rods is 3 pieces of Φ50×150mm, 5 pieces of Φ40×150mm, and 5 pieces of Φ30×150mm) for 10 minutes, and the grain shape is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com