Mixed treatment method of waste plastics

A technology for mixed treatment and waste plastics, which is applied in the field of waste plastics treatment and recycling of waste plastics. It can solve the problems that waste plastics cannot be recycled, cannot be automatically and accurately subdivided, and has high requirements for plastics, so as to reduce damage to the environment and reduce Sorting, cleaning and post-processing processes, and the effect of improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

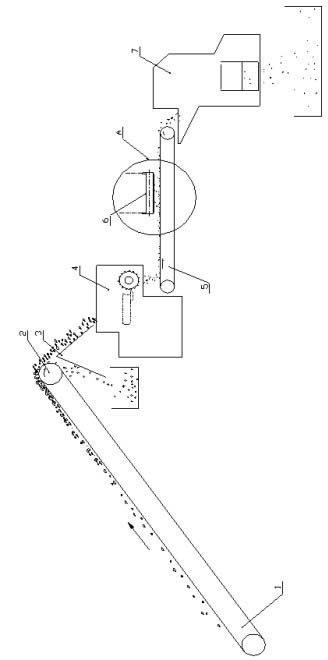

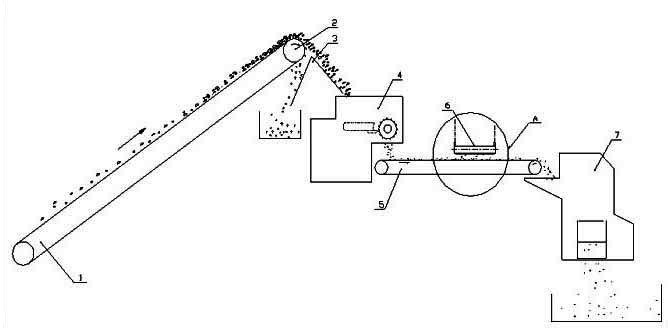

[0027] After the waste plastics are collected, the recycled materials are first roughly sorted, mainly to separate the large non-plastic substances that are not easily broken and easy to separate, such as glass products, large metal objects, large paper fabrics, etc. later as figure 1 As shown, the remaining various waste plastics and a small amount of impurities are transported by the conveying device 1 to the shredder 4 silo configured in the next process for shredding. A permanent magnetic roller can be installed on the upper end of the conveyor to remove most of the ferromagnetic materials that have not been manually selected to protect the mechanical equipment in the next process. In the 4 silo of the shredder, it mainly crushes large plastic parts and recycled plastics that have been compressed and bundled in the recycling field. And some small pieces of plastic with metal inside shredded.

[0028] The shredded mixed plastics are transferred to the next process through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com