Hollow fiber acidproof and permeable molecular sieve membrane and its preparation method

A molecular sieve and fiber technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of high investment cost, small filling area, etc., and achieve the effect of excellent separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 hollow fiber T-type molecular sieve membrane

[0027] The support used to prepare the T-type molecular sieve membrane is YSZ (yttria-stabilized zirconia) hollow fiber with an average pore diameter of 1.28 μm, a porosity of 52.3%, an outer diameter of 1.86 mm and a wall thickness of 0.40 mm.

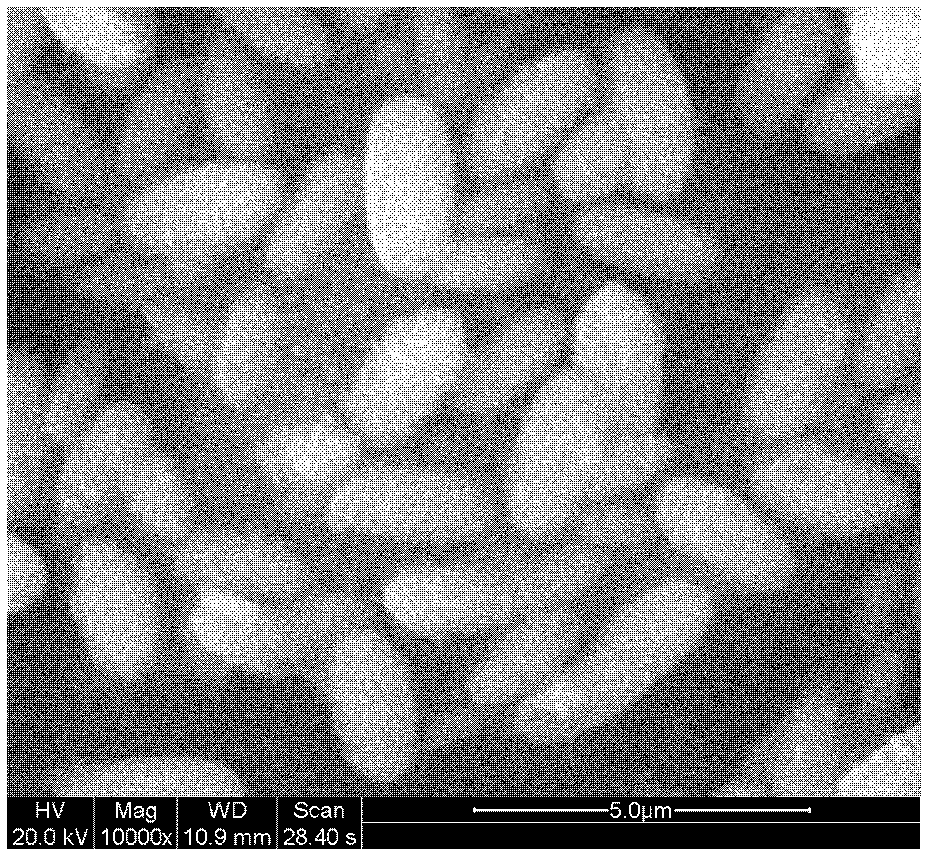

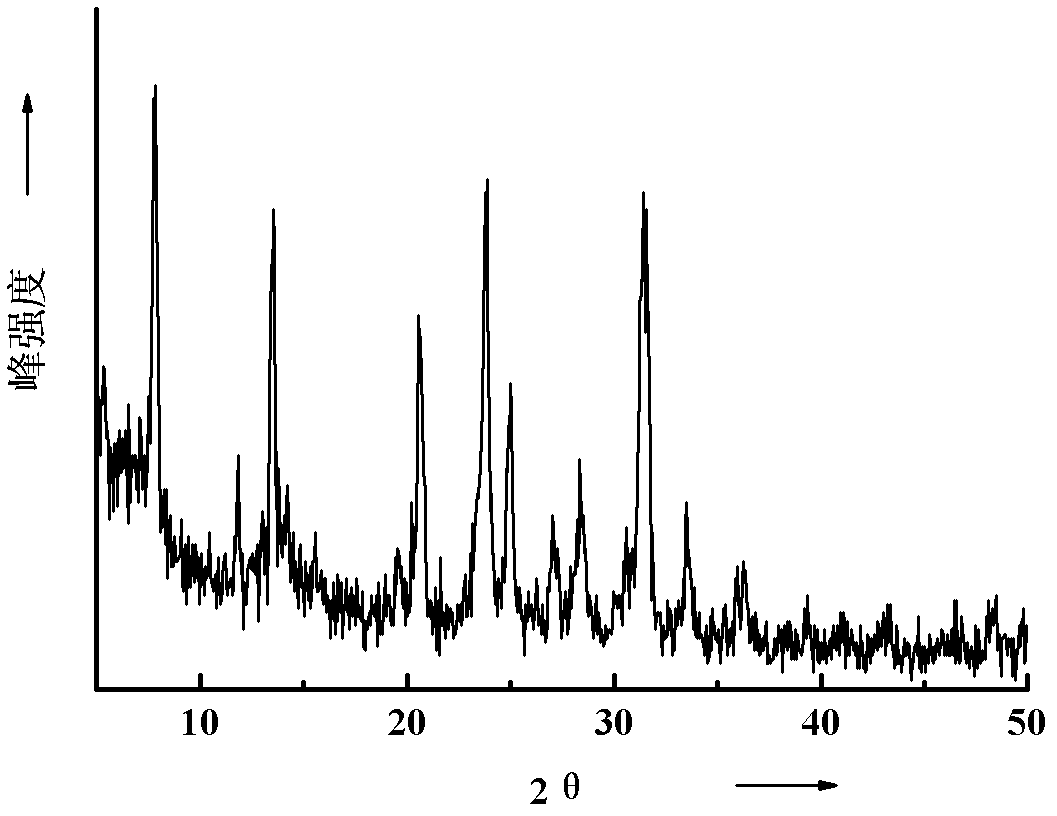

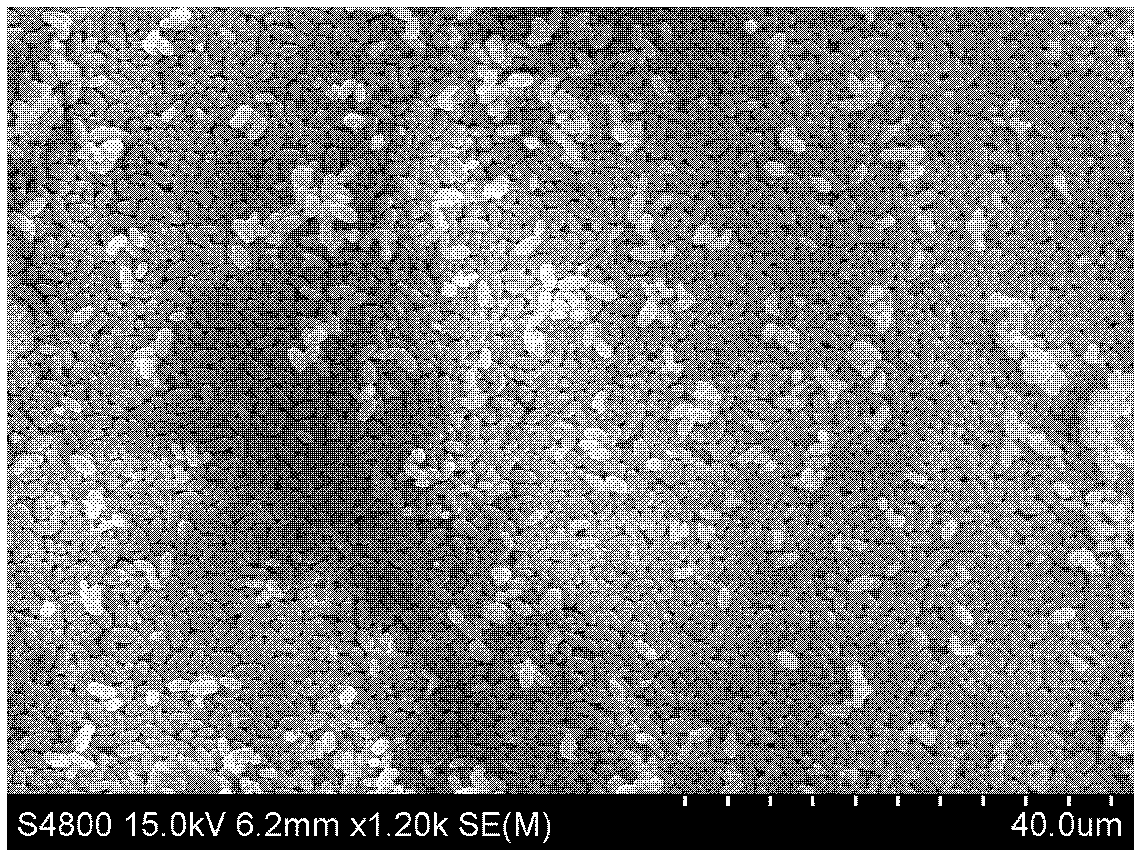

[0028] T-type molecular sieve seeds with a particle size of about 2 μm (such as figure 1 , 2 ) is formulated into an emulsion, and the seed crystals are evenly coated on the surface of the support body by the wiping method, and dried to obtain a YSZ hollow fiber support body coated with T-type molecular sieve crystal seeds (such as image 3 ).

[0029] Molar Composition to SiO 2 : Al 2 o 3 :Na 2 O:K 2 O:H 2 O=1: 0.05: 0.26: 0.09: 17 synthetic solution (wherein the silicon source is silica sol; the aluminum source is aluminum hydroxide) was stirred and aged at room temperature for 24h, poured into a polytetrafluoro reactor; the coated crystal ...

Embodiment 2

[0030] The preparation of embodiment 2 hollow fiber T-type molecular sieve membranes

[0031] The T-type molecular sieve seed crystals were mechanically crushed in advance by wet ball milling technology to obtain small-sized T-type molecular sieve seeds with a particle size of about 0.29 μm. Coating YSZ-doped α-Al with broken seed crystals by ball milling by vacuum suction 2 o 3 Hollow fiber surface. The support has an average pore diameter of 0.35 μm, a porosity of 35%, an outer diameter of 3.60 mm, and a wall thickness of 0.9 mm.

[0032] Molar Composition to SiO 2 : Al 2 o 3 :Na 2 O:K 2 O:H 2 The synthesis solution of O=1:0.02:0.4:0.02:13 (where the silicon source is silica sol; the aluminum source is aluminum hydroxide) was stirred and aged at room temperature for 12 hours. The synthesis temperature was 120° C., and the synthesis time was 20 hours to prepare a T-type molecular sieve membrane with a thickness of 30 μm. All the other operating conditions are the sa...

Embodiment 3

[0033] The preparation of embodiment 3 hollow fiber T-type molecular sieve membranes

[0034] α-Al doped with silica 2 o3 The hollow fiber is used as a support body, and a T-type molecular sieve membrane is prepared. The average pore diameter of the support is 5.78 μm, the porosity is 28.4%, the outer diameter is 0.80 mm, and the wall thickness is 0.2 mm.

[0035] T-type molecular sieve seeds with a particle size of 8 μm were prepared into a suspension with a concentration of 3 wt.%, and dispersed uniformly by ultrasonication. The support body is soaked in the suspension for 30 seconds, then taken out, and dried to obtain a hollow fiber support body coated with seed crystals.

[0036] Molar Composition to SiO 2 : Al 2 o 3 :Na 2 O:K 2 O:H 2 The synthesis liquid of O=1:0.07:0.2:0.27:25 (wherein the silicon source is precipitated silica; the aluminum source is sodium metaaluminate) is stirred and aged at room temperature for 12h, and then put into a polytetrafluoroethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com