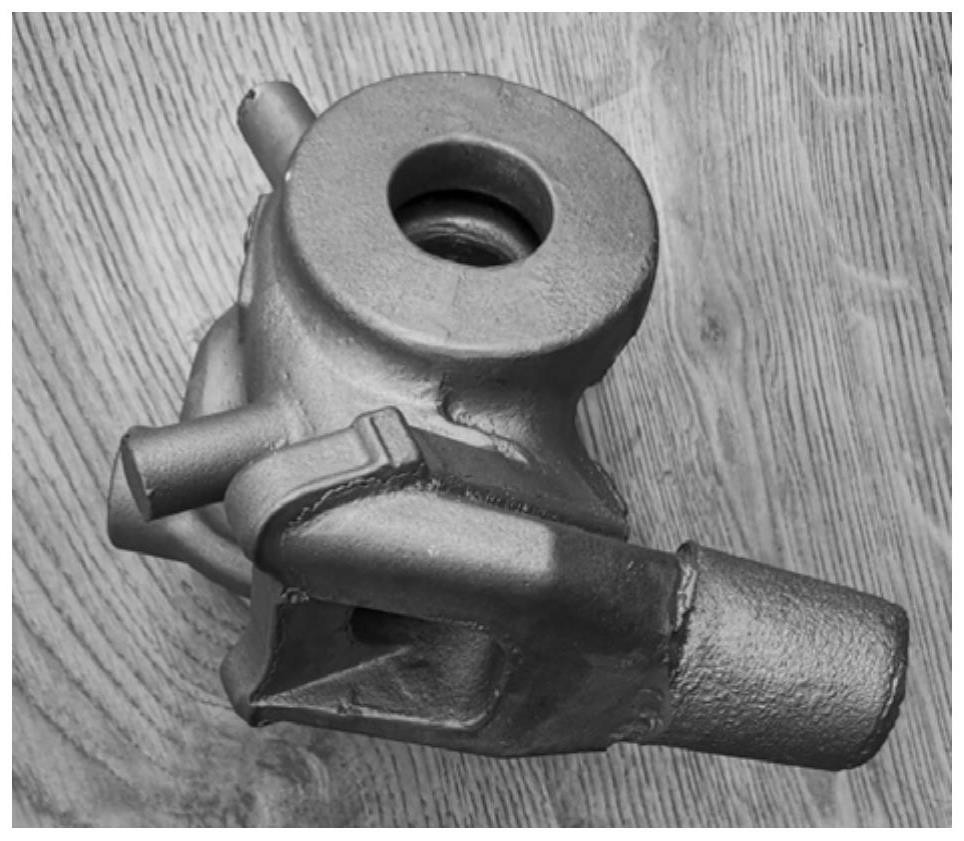

Anti-oxidation and anti-fatigue CREE rare earth heat-resistant steel for turbocharger shell and preparation method of CREE rare earth heat-resistant steel

A turbocharger and anti-oxidation technology, applied in the field of auto parts, can solve problems such as insufficient oxidation resistance, low alloy cost, thermal fatigue cracking, etc., achieve obvious technical and cost advantages, solve high-temperature oxidation, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this embodiment, the turbocharger housing is made of anti-oxidation and fatigue-resistant CNRE rare earth heat-resistant steel, and the specific components are as follows by weight percentage:

[0054] element Content (mass fraction, wt.%) C+N 0.6 (C0.20, N0.40) Si 1.5 mn 7.5 Cr 18.8 Ni 2.5 V 0.15 Nb 0.08 RE 0.025 Fe margin

[0055] In this embodiment, the preparation process of the anti-oxidation and fatigue-resistant CNRE rare earth heat-resistant steel for the turbocharger housing is as follows:

[0056] The molten steel is smelted in an intermediate frequency furnace, and the lining of the intermediate frequency furnace is made of alkaline refractory materials and alkaline ladles. Alloy ingredients are scrap steel, metal chromium, ferrochrome nitride, high carbon ferrochrome, electrolytic manganese, nickel plate, ferrosilicon, ferroniobium, ferrovanadium, etc. Among them, ferrochromium nitride...

Embodiment 2

[0061] In this embodiment, the turbocharger housing is made of anti-oxidation and fatigue-resistant CNRE rare earth heat-resistant steel, and the specific components are as follows by weight percentage:

[0062]

[0063]

[0064] In this embodiment, the preparation process of the anti-oxidation and fatigue-resistant CNRE rare earth heat-resistant steel for the turbocharger housing is as follows:

[0065] The molten steel is smelted in an intermediate frequency furnace, and the lining of the intermediate frequency furnace is made of alkaline refractory materials and alkaline ladles. Alloy ingredients are scrap steel, low-carbon ferrochrome, nitrided ferrochrome, high-carbon ferrochrome, electrolytic manganese, nickel plate, ferrosilicon, ferro-niobium, ferro-vanadium, etc. Among them, ferrochromium nitride is crushed to less than 50mm, together with ferrosilicon, high-carbon ferrochrome, low-carbon ferrochrome, scrap steel, etc., are preheated at 650°C for more than 4 hou...

Embodiment 3

[0070] In this embodiment, the turbocharger housing is made of anti-oxidation and fatigue-resistant CNRE rare earth heat-resistant steel, and the specific components are as follows by weight percentage:

[0071] element Content (mass fraction, wt.%) C+N 0.9 (C0.25, N0.65) Si 2.0 mn 10.0 Cr 15.5 Ni 5.6 V 0.10 Nb 0.25 RE 0.010 Fe margin

[0072] In this embodiment, the preparation process of the anti-oxidation and fatigue-resistant CNRE rare earth heat-resistant steel for the turbocharger housing is as follows:

[0073] The molten steel is smelted in an intermediate frequency furnace, and the lining of the intermediate frequency furnace is made of alkaline refractory materials and alkaline ladles. Alloy ingredients are scrap steel, low-carbon ferrochrome, nitrided ferrochrome, high-carbon ferrochrome, electrolytic manganese, nickel plate, ferrosilicon, ferro-niobium, ferro-vanadium, etc. Among them, ferrochro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com