Room temperature synthetic polyester polyether polycarboxylic acid water-reducing agent and preparation method thereof

A technology for synthesizing polyester polyether and normal temperature, which is applied in the field of synthesizing polyester polyether polycarboxylate water reducer and its preparation at normal temperature, can solve the problems of cement's poor applicability, poor adaptability and complex synthesis, etc. Achieve the effects of good slump protection, small usage, and improvement of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

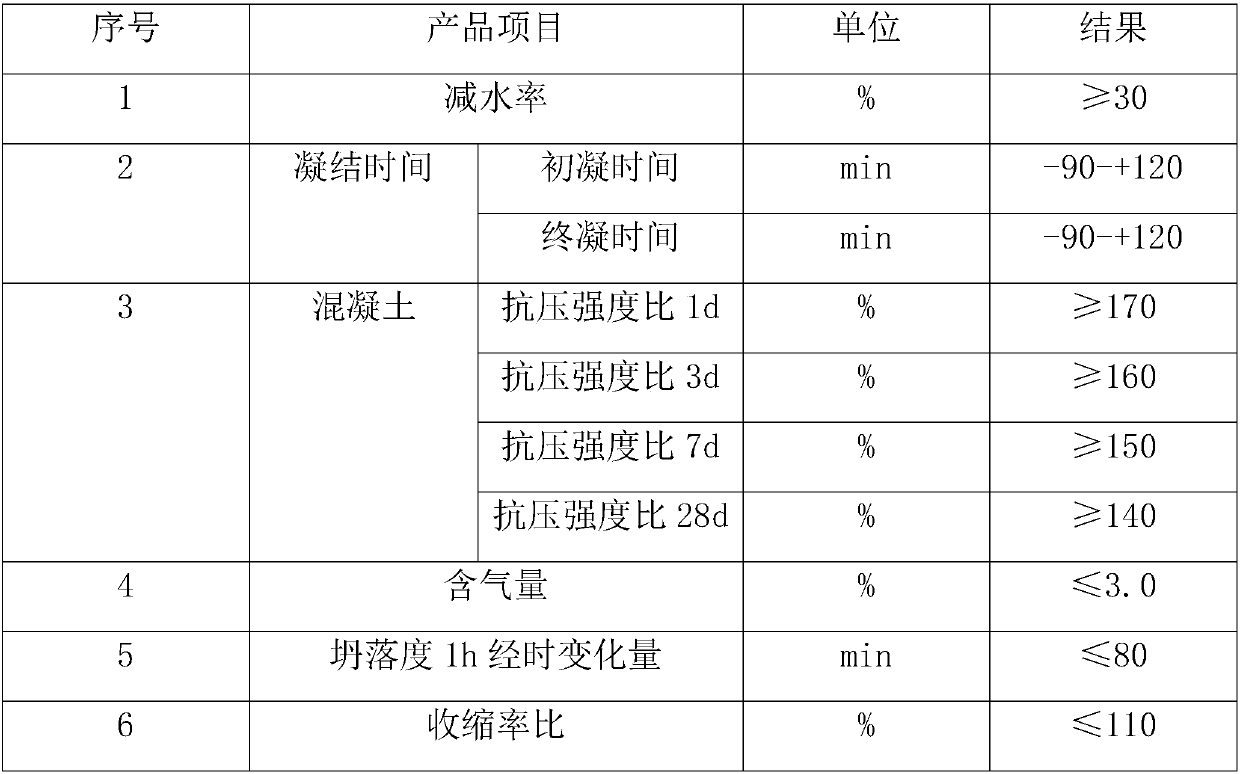

[0039] Preparation of 1000kg polycarboxylate superplasticizer as an example

[0040] Prepare polycarboxylate water reducer, its proportioning is calculated according to weight percentage;

[0041] Put 350kg of tap water and 450kg of isobutylene alcohol polyoxyethylene ether into the reaction kettle, stir at room temperature for 2.0h until fully dissolved; configure solution A in the mixing kettle: put in 50kg of tap water, 40kg of methacrylic acid, 1.5kg of mercaptoethanol, and L-ascorbic acid Sodium 0.55g, stir for 30min until uniform.

[0042] Configure solution B in the mixing tank: put in 65kg of tap water, 40kg of polyethylene glycol monomethyl ether acrylate, and stir for 30 minutes until uniform.

[0043] Put 3 kg of ammonium persulfate into the reaction kettle, stir for 15 minutes, and at the same time, drop solutions A and B into the reaction kettle at a constant speed. Solution A dripping time 3h, solution B dropping time 2.5h. After the dropwise addition of the s...

Embodiment 2

[0045] Preparation of 1000kg polycarboxylate superplasticizer as an example

[0046] To prepare polycarboxylate water reducer, the proportion is calculated according to weight percentage, put 365kg of tap water and 426kg of allyl polyoxyethylene ether into the reactor, stir at room temperature for 2.0h until fully dissolved; configure solution A in the mixing tank: Put in 50kg of tap water, 48.3kg of methyl methacrylate, 1.7kg of mercaptopropionic acid, and 0.67g of sodium L-ascorbate, and stir for 30 minutes until uniform.

[0047] Configure solution B in the mixing tank: put in 63kg of tap water, 33g of polyethylene glycol monomethyl ether methacrylate, and 10kg of sodium allyl sulfonate, and stir for 30 minutes until uniform.

[0048] Put 2.5 kg of hydrogen peroxide into the reaction kettle, stir for 15 minutes, and at the same time, add solutions A and B dropwise to the reaction kettle at a uniform speed. The solution A was added dropwise for 3 hours, and the solution B w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com