Asphalt recycling agent for hot recycling of asphalt on asphalt road surface

A technology of asphalt regenerant and asphalt pavement, which is applied in the field of asphalt regenerant for asphalt thermal regeneration of asphalt pavement, which can solve the problems of low safety index and inconspicuous regeneration effect, achieve good safety, maintain high temperature anti-rutting ability , good regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

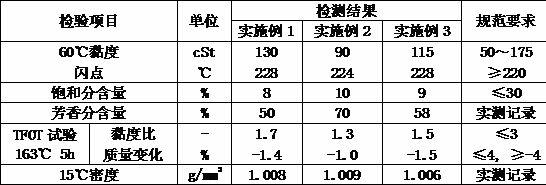

Embodiment 1

[0020] Example 1 The asphalt regenerant used for asphalt thermal regeneration of asphalt pavement, the mass percentage of each component is as follows:

[0021] Aromatic oil 19%

[0022] Heavy oil 60%

[0023] Liquid petroleum resin 20%

[0024] Stabilizer 1%.

Embodiment 2

[0025] Example 2 The asphalt regenerant used for asphalt pavement asphalt thermal regeneration, the mass percentage of each component is as follows:

[0026] Aromatic oil 70%

[0027] Heavy oil 24.8%

[0028] Liquid petroleum resin 5%

[0029] Stabilizer 0.2%.

Embodiment 3

[0030] Example 3 The asphalt regenerant used for asphalt thermal regeneration of asphalt pavement, the mass percentage of each component is as follows:

[0031] Aromatic oil 49.5%

[0032] Heavy oil 20%

[0033] Liquid petroleum resin 30%

[0034] Stabilizer 0.5%.

[0035] In each of the above-mentioned embodiments: one or more of furfural oil, extracted oil, rubber oil, etc. are selected as the aromatic oil, which is characterized in that the aromatic content is not less than 80%, and the flash point is greater than 220°C. The heavy oil is petroleum-grade heavy fuel oil or burning oil; the liquid petroleum resin is selected from Qilu Petrochemical, and the resin can be well compatible with aromatic oil and heavy oil. The stabilizer is preferably sulfur-based asphalt stabilizer from Lanzhou Lanyue Chemical Co., Ltd., the main component is sulfur, which is an existing commercial product.

[0036] The preparation method of the asphalt rejuvenator for asphalt pavement asphalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com