Enzymatic packing for reactive distillation as well as coating method and application of enzymatic packing

A technology of catalytic packing and reactive distillation, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem that the activity and stability of free enzymes are easily affected by conditions such as temperature and pH, free enzymes Enzyme can not be recycled, waste economy and other problems, to achieve the effect of obvious economy and novelty, mild conditions, and reduce pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of solution A: Mix 0.35 g of tetramethoxysilane (TMOS), 1.4 g of methyltrioxymethylsilane, and 1.6 g of methanol, respectively, and stir in an ice-water bath for 3 minutes.

[0031] Preparation of solution B: Take 0.225g of sodium fluoride, 0.075g of polyethylene glycol (400), 0.8g of CALB enzyme solution (protein content is 10.9mg / ml), and 0.55g of deionized water to mix and stir at room temperature 4 minutes.

[0032] Drain solution B into solution A, stir in an ice-water bath for 3 minutes and then move to room temperature.

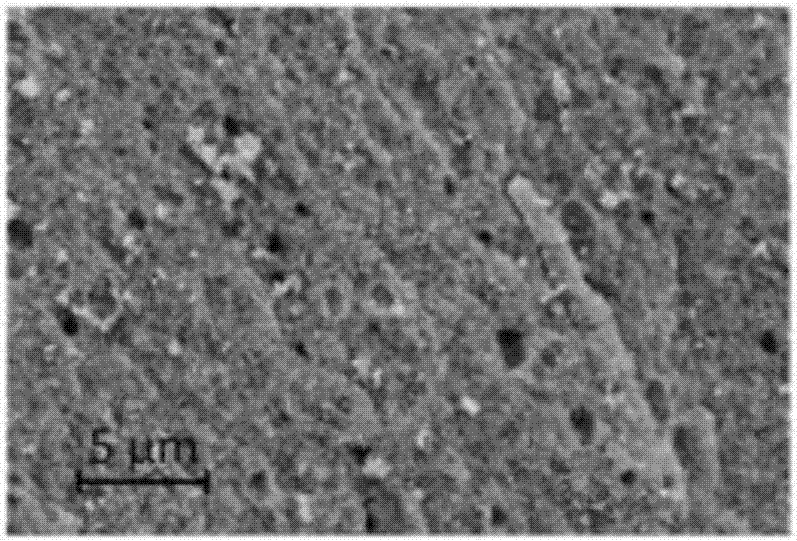

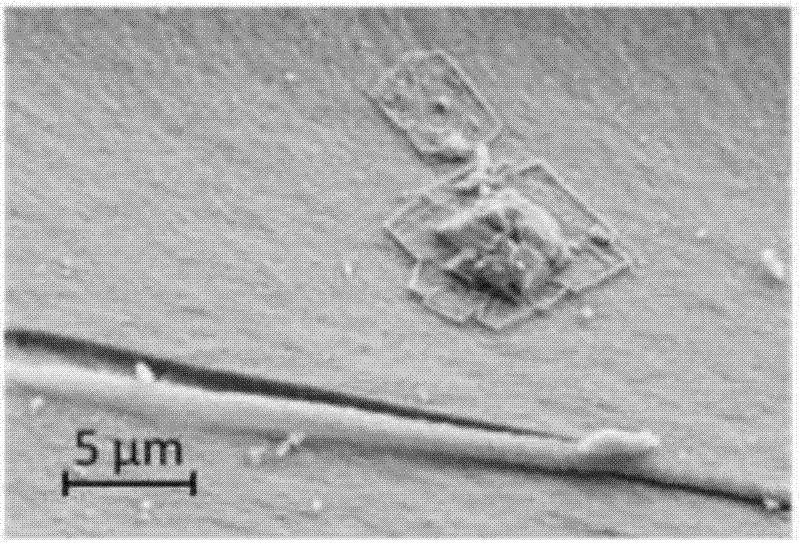

[0033] The sol was divided into two equal parts, one part was washed three times with phosphate buffer (PH=7.5) and then dried to obtain a gel, as shown in the attached figure 1 shown. The other part was immersed in the sol of CY-500 type filler for 20s, then taken out, placed at room temperature for 20s, then immersed in the sol again, and this step was repeated 12 times until the sol solution solidified into a gel. Dry the gel-c...

Embodiment 2

[0037] Preparation of solution A: Mix 0.4 g of tetramethoxysilane (TMOS), 1.45 g of methyltrioxymethylsilane, and 1.7 g of methanol respectively, and stir in an ice-water bath for 3 minutes.

[0038] Preparation of solution B: get 0.25g sodium fluoride, polyethylene glycol (400) 0.075g, CALB enzyme solution 0.525g (protein content is 10.9mg / ml), deionized water 0.6g to mix respectively, stir at room temperature for 4 minute.

[0039] Drain solution B into solution A, stir in an ice-water bath for 3 minutes and then move to room temperature.

[0040] Immerse the CY-500 type filler in the sol for 20 seconds, take it out, place it at room temperature for 20 seconds, and then immerse it in the sol again. Repeat this step 13 times. Dry the filler at room temperature for 48 hours until the weight remains constant, and then store it at low temperature.

[0041] Test the activity of CALB enzyme contained in the filler surface coating prepared above: the enzyme activity was measured...

Embodiment 3

[0044] Preparation of solution A: Mix 0.9 g of tetramethoxysilane (TMOS), 2.7 g of methyltrioxymethylsilane, and 3.1 g of methanol, respectively, and stir in an ice-water bath for 3 minutes.

[0045] The preparation of solution B: get 0.4g sodium fluoride, polyethylene glycol (400) 0.2g, CALB enzyme solution 1.4g (protein content is 10.9mg / ml), deionized water 1.3g to mix respectively, stir at room temperature for 4 minute.

[0046] Drain solution B into solution A, stir in an ice-water bath for 3 minutes and then move to room temperature.

[0047] Immerse the CY-500 type filler in the sol for 20 seconds, take it out, place it at room temperature for 20 seconds, and then immerse it in the sol again. Repeat this step 10 times. Dry the filler at room temperature for 48 hours until the weight remains constant, and then store it at low temperature.

[0048] Test the activity of CALB enzyme contained in the filler surface coating prepared above: the enzyme activity was measured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com