Stable polypeptide composition and application thereof

A polypeptide composition and stable technology, applied in the field of polypeptide raw material preparation, can solve problems such as easy generation of impurities, difficulties in subsequent formulations, and impact on use efficacy, and achieve good safety, not easy to inactivate, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Preparation of Acetyl Hexapeptide-8 and Palmitoyl Pentapeptide-4 Composition 1

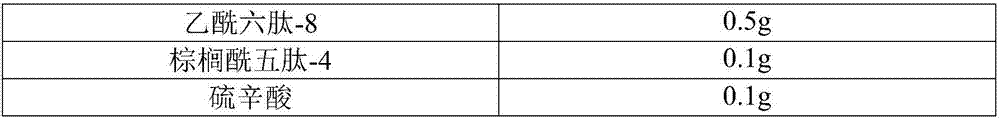

[0046] (1) The formula is shown in Table 1:

[0047] Table 1

[0048] Acetyl Hexapeptide-8

[0049] (2) Preparation process: add 80g of Tween-80 and 500g of purified water into the batching tank, and stir well. Add 5g of palmitoyl pentapeptide-4 and 10g of acetyl hexapeptide-8 in turn. After continuous stirring and dissolving at 1000rpm, dissolve 2g of lipoic acid and 3g of methionine with 300g of purified water, add them to the batching tank, and then add 10g of caprylic acid. alcohol, 20g phenoxyethanol, stir well. Finally, slowly drop 2mol / L sodium hydroxide solution into the formula reaction tank, increase the stirring speed to 1500rpm, adjust the pH to 5.5, and then fix the weight to 1000g with purified water. Filtered through sterile PES filter, the solution is clear and transparent.

Embodiment 2

[0050] Example 2: Preparation of Acetyl Hexapeptide-8 and Palmitoyl Pentapeptide-4 Composition 2

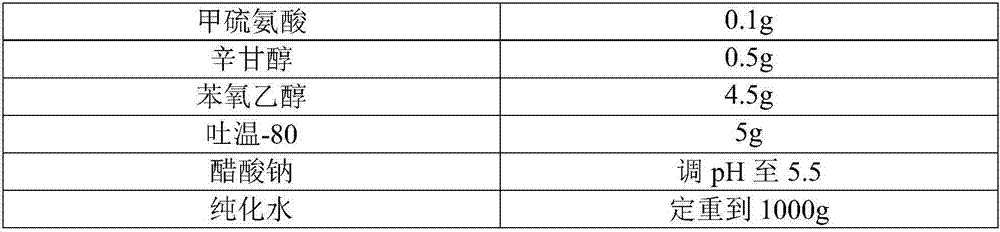

[0051] (1) The formula is shown in Table 2:

[0052] Table 2

[0053]

[0054]

[0055](2) Preparation process: add 5g of Tween-80 and 500g of purified water into the batching tank, and stir well. Add 0.1 g of palmitoyl pentapeptide-4 and 0.5 g of acetyl hexapeptide-8 in turn. After continuous stirring and dissolving at 1000 rpm, dissolve 0.1 g of lipoic acid and 0.1 g of methionine with 300 g of purified water, and add them to the batching tank. Add 0.5 g of caprylyl glycol and 4.5 g of phenoxyethanol, and stir well. Finally, slowly drop 2mol / L sodium acetate solution into the formula reaction tank, increase the stirring speed to 1500rpm, adjust the pH to 5.5, and then use purified water to fix the weight to 1000g. Filtered through sterile PES filter, the solution is clear and transparent.

Embodiment 3

[0056] Example 3: Preparation of Acetyl Hexapeptide-8 and Palmitoyl Pentapeptide-4 Composition 3

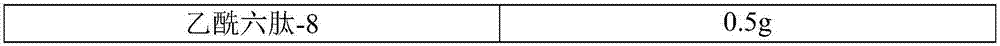

[0057] (1) The formula is shown in Table 3:

[0058] table 3

[0059] Acetyl Hexapeptide-8

[0060] (2) Preparation process: add 8g of Tween-80 and 500g of purified water into the batching tank, and stir well. Add 0.1g of palmitoyl pentapeptide-4 and 0.5g of acetyl hexapeptide-8 in turn. After continuous stirring at 1000rpm, dissolve 10g of carnosine and 40g of cysteine with 300g of purified water, add them to the batching tank, and then add 2g of glycerol. , 8g phenoxyethanol, stir well. Finally, slowly drop 2mol / L sodium carbonate solution into the formula reaction tank, increase the stirring speed to 1500rpm, adjust the pH to 6.0, and then fix the weight to 1000g with purified water. Filter through sterile PES filter, the solution should be clear and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com