Design method of hot recycled asphalt mixture with high RAP proportion

A technology of asphalt mixture and design method, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of unsatisfactory performance of recycled asphalt mixture, achieve material cost reduction, and have obvious economic and environmental advantages. The effect of increasing the blending ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

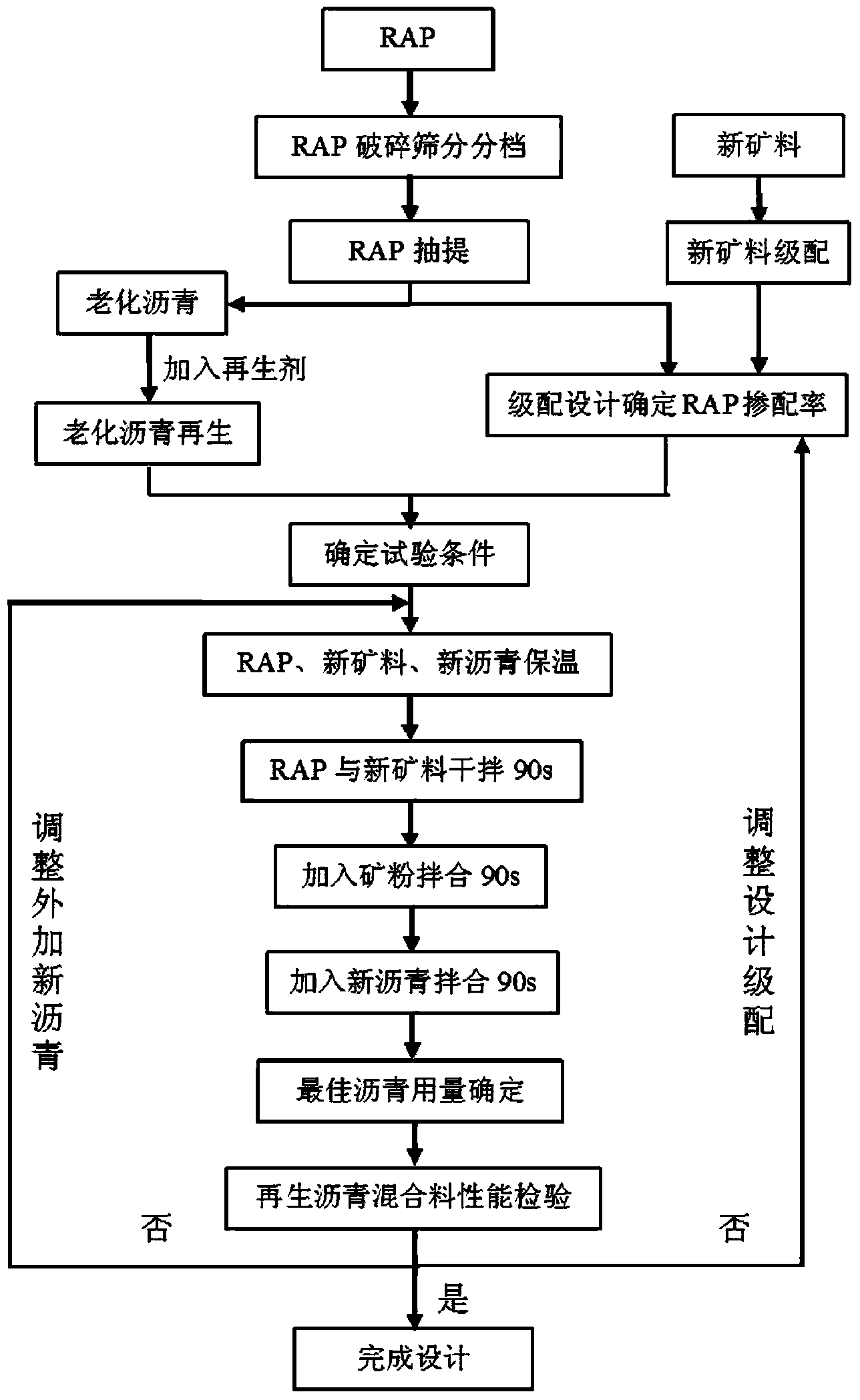

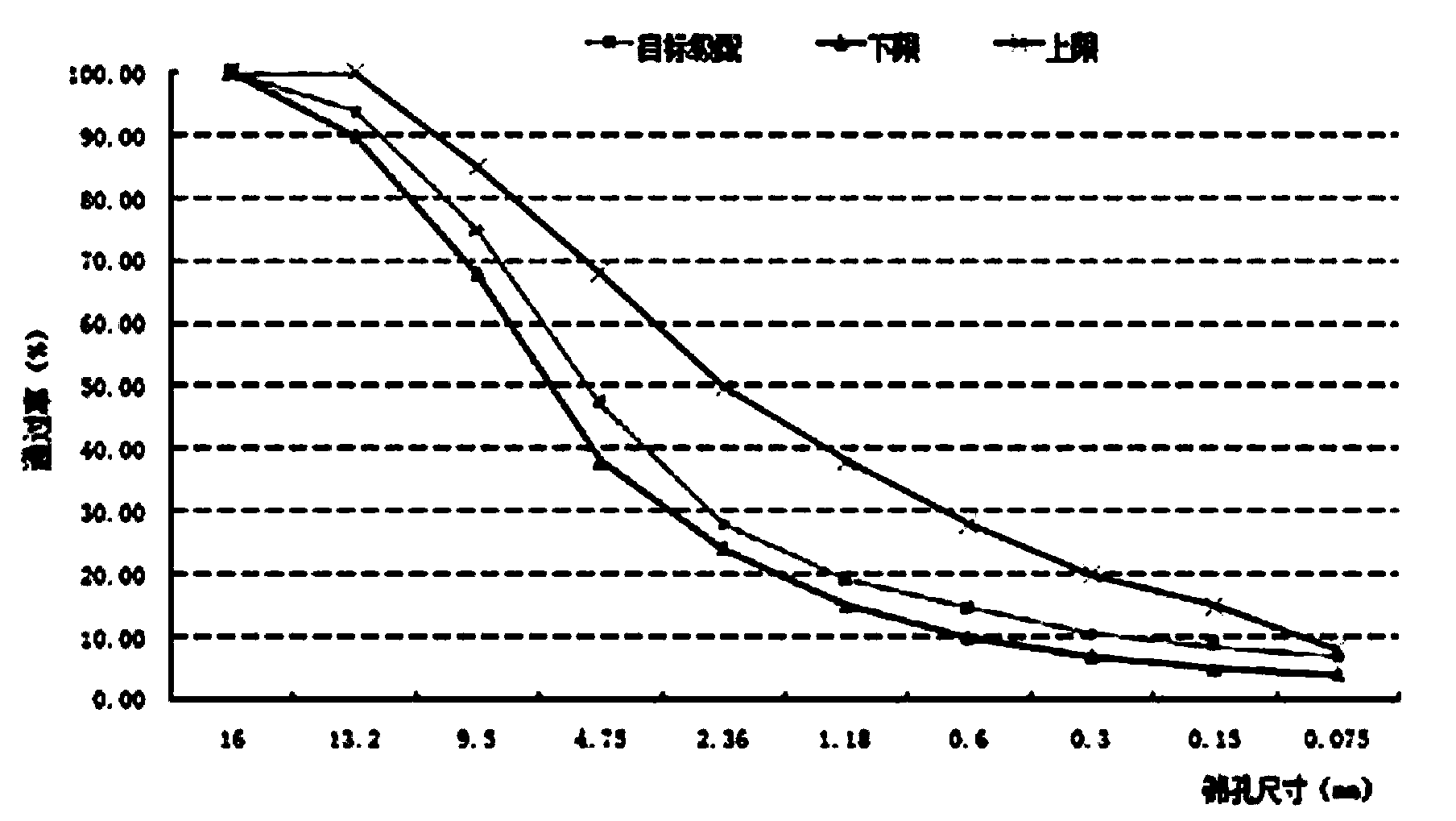

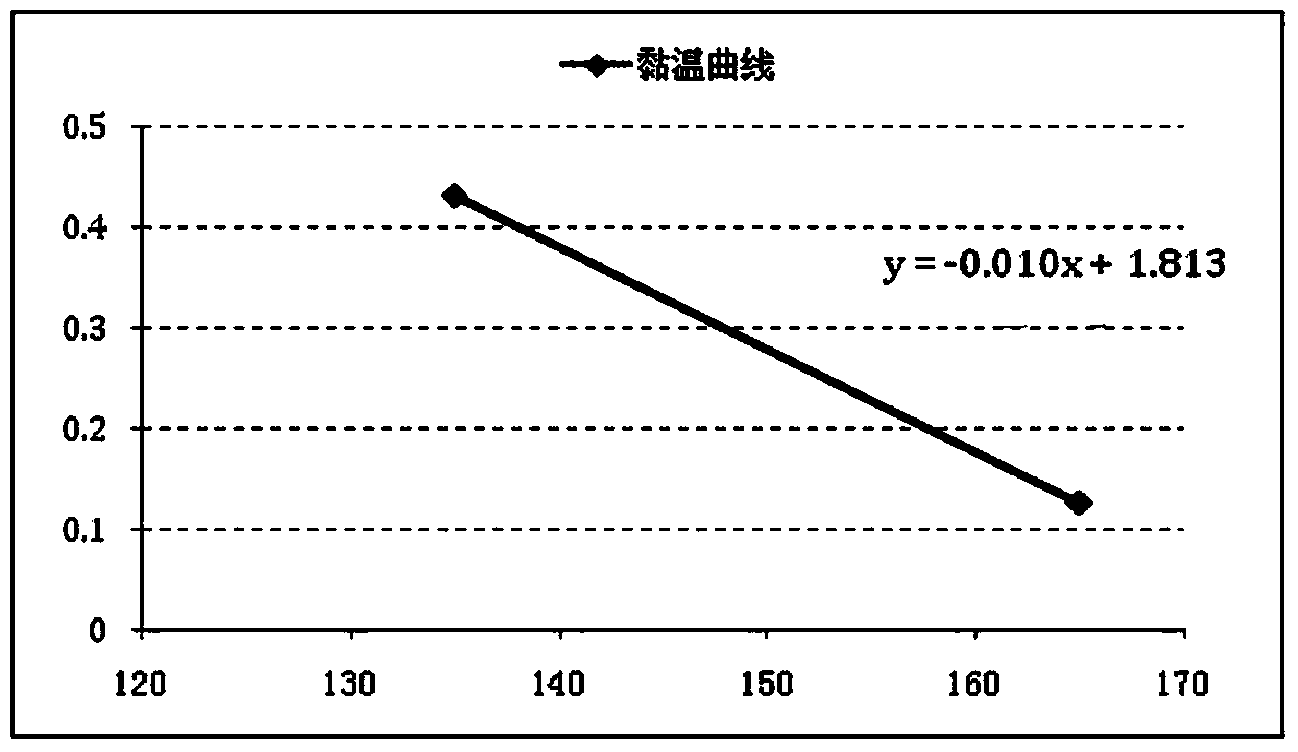

[0055] A Design Method of Hot Recycled Asphalt Mixture with High RAP Ratio

[0056] This embodiment takes the design of AC-13C asphalt mixture as an example, the details are as follows:

[0057] 1. RAP broken into files

[0058] The RAP after road milling is crushed and screened, classified according to the particle size, and the RAP with a particle size smaller than 2.36mm is removed, and finally three grades of 3-5mm, 5-10mm, and 10-15mm are obtained. The RAP material is kept in a dry state during the crushing and screening, and the water content in the RAP material is controlled to be 2% by mass of the RAP material. The crushing and sieving is to reduce the variability of the RAP material.

[0059] 2. RAP extraction

[0060] The graded RAP is extracted with a fully automatic extractor, and the gradation after extraction of each grade of RAP and the content of aged asphalt in each grade of RAP are tested. According to the T0726-2011 method of recovering asphalt from asph...

Embodiment 2

[0095] A design method for hot recycled asphalt mixture with high RAP ratio, taking the design of AC-13C recycled asphalt mixture as an example, including controlling the variability of RAP materials, improving the regeneration effect of regenerant and determining the appropriate test conditions.

[0096] In this embodiment, the control of the variability of the RAP material includes the step of crushing and screening the RAP material after the original pavement is crushed, the RAP material is kept dry during the crushing and screening, and the moisture content in the RAP material is controlled to account for the RAP material. The mass percentage of the material is 2%. The crushing and sieving is to reduce the variability of the RAP material.

[0097]In this embodiment, after the RAP material is crushed and screened, it is classified according to the size of the particle size; -10mm, 10-15mm, the three grades of RAP materials are stored separately. to prevent mixing with eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com