Normal temperature regeneration modifier for waste asphalt mixture and preparation method thereof

A waste asphalt and mixture technology, which is applied in the field of waste asphalt mixture normal temperature regeneration modifier and its preparation, can solve the problems of restricting the secondary utilization of RAP, restricting the application of technology, and high cost of equipment transformation, etc., and achieve good performance, The effect of high RAP blending ratio and low production temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

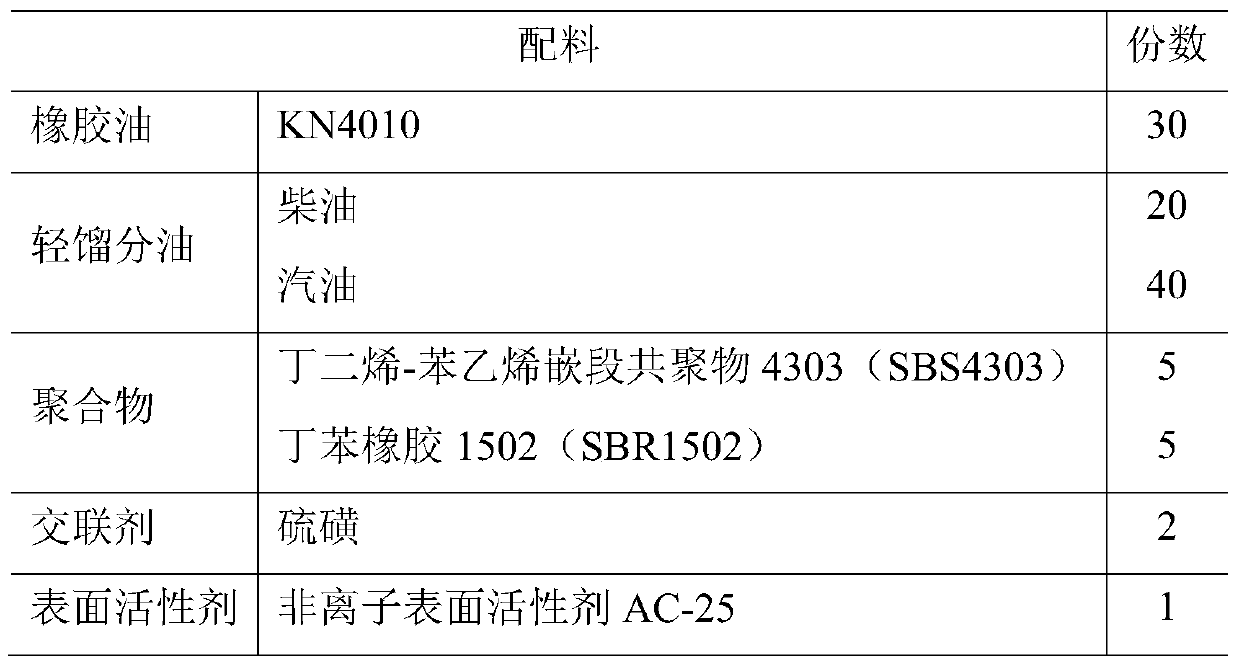

[0032] Preparation formula of waste asphalt mixture normal temperature regeneration modifier:

[0033]

[0034] Preparation:

[0035] 1) Add a certain weight portion of polymer SBS4303, SBR1502 and light distillate oil (gasoline, diesel) mixture into the stirring tank, stir and dissolve at 25°C, and stir and dissolve for 48 hours;

[0036] 2) Add naphthenic rubber oil KN4010 (naphthenic content > 40%, kinematic viscosity 10mm) into the stirred tank in step 1) 2 / s), cross-linking agent (sulfur), surfactant (nonionic surfactant AC-25), and continue to stir for 40min, and the obtained liquid mixture is the normal temperature regeneration modifier of the waste asphalt mixture.

Embodiment 2

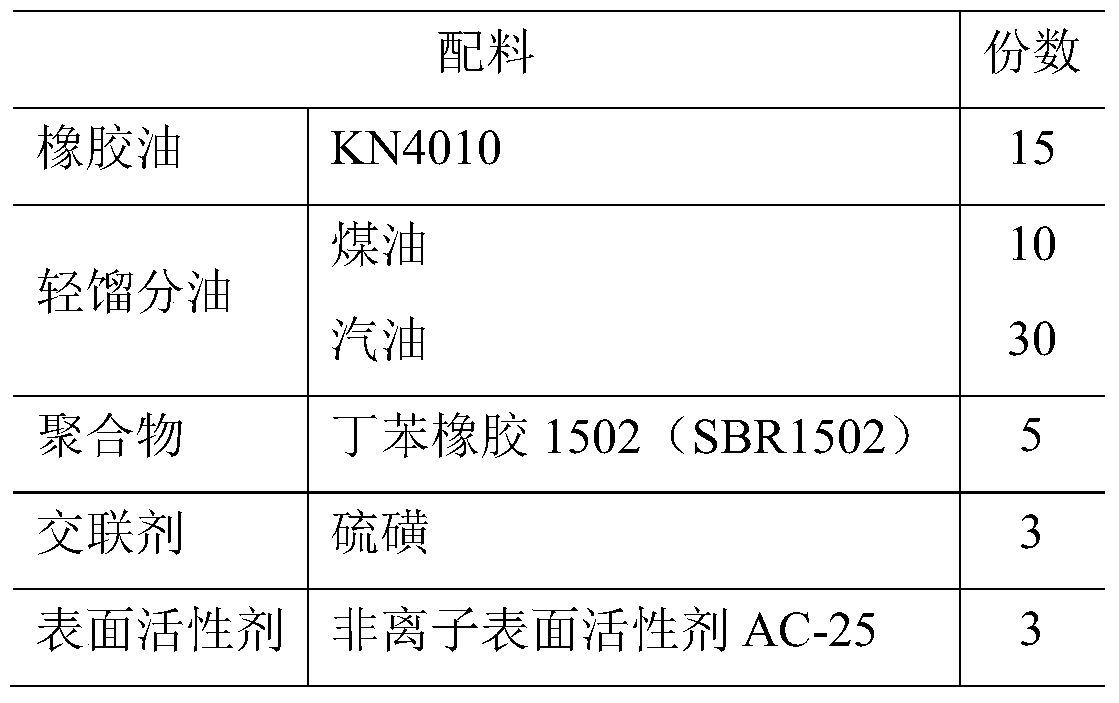

[0038] Preparation formula of waste asphalt mixture normal temperature regeneration modifier:

[0039]

[0040] Preparation:

[0041] Refer to the method of Example 1 to prepare the waste asphalt mixture normal temperature regeneration modifier of this example, the difference is that the stirring and dissolving time of step 1) is 24 hours; the stirring time of step 2) is 30 minutes.

Embodiment 3

[0043] Preparation formula of waste asphalt mixture normal temperature regeneration modifier:

[0044]

[0045] Preparation:

[0046] With reference to the method of Example 1, the waste and old asphalt mixture normal temperature regeneration modifier is prepared, the difference is that step 1) is omitted, and light distillates (kerosene and gasoline), naphthenic rubber oil KN4010 (naphthene content > 40%, kinematic Viscosity 10mm 2 / s), crosslinking agent (sulfur), surfactant (nonionic surfactant AC-25) are added in the stirring tank, stirring temperature is 25 ℃, stirring 20min, the obtained liquid mixture is the waste asphalt mixture Normal temperature regeneration modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com