Microwave thermal regeneration asphalt mixing station capable of infinitely adjusting mixing ratio of new and old materials

An asphalt mixing and thermal regeneration technology, applied in roads, road repair, roads, etc., can solve the problems of aging of mixtures, environmental pollution, inability to further increase the mixing ratio, etc., to improve work efficiency, improve mixing quality, reduce Generation and Emission Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

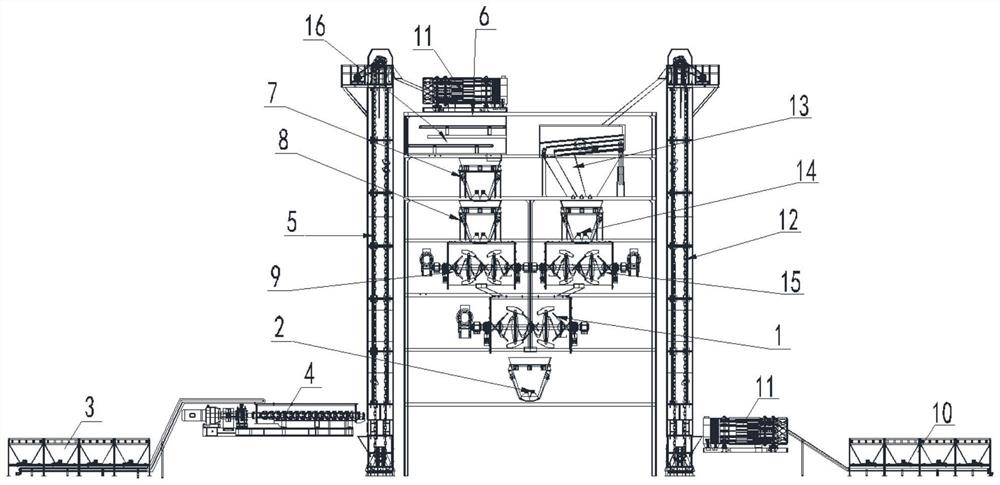

[0027] The structure and working principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] combine figure 1 As shown, the present invention provides a microwave thermal regeneration asphalt mixing plant that can infinitely adjust the mixing ratio of new and old materials, including: RAP material configuration mixing system, new material configuration mixing system, total mixing device 1, and finished material storage bin 2 .

[0029] Among them, the RAP material configuration and mixing system is composed of intermittent weighing batching bin 3, continuous mixing tank 4, RAP elevator 5, hot air microwave drying device 6, RAP storage bin 7, RAP metering bin 8, and RAP mixer 9; The discharge port of the intermittent weighing batching bin 3 is connected to the feed port of the continuous mixing tank 4 through the first conveying device, and the discharge port of the continuous mixing tank 4 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com