Rejuvenating agent, mixture and preparation for hot-in-place recycled asphalt

A technology of recycled asphalt and regenerated agent, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of low blending rate of old materials, high mixing temperature, and high cost of regenerated agent, and achieve good anti-stripping performance and old The effect of high material mixing rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0033] Example A: Preparation of a rejuvenating agent for hot-in-place reclaimed asphalt.

[0034] Put the waste edible oil into the reaction kettle and heat it to 80-90°C; add epoxy fatty acid methyl ester, distilled tall oil and methyl silicone oil to the reaction kettle with the waste edible oil in the stirring environment, keep stirring for 20 -30min; heat the mixture in the reactor to 90-110°C, add furfural to extract the oil, stir for 3-5min, and discharge. The regenerant is preferably maintained at 70°C.

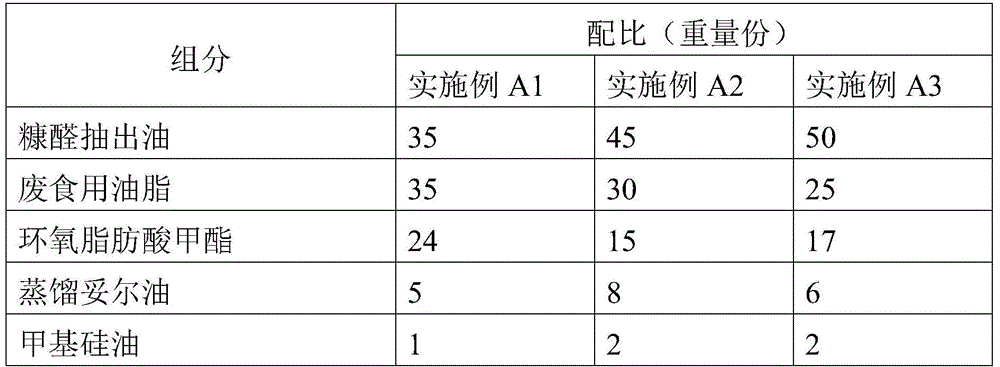

[0035] The ratio of each component in the regenerant is shown in Table 1 below.

[0036] Table 1: Formulas of regenerants for hot-in-place recycled asphalt

[0037]

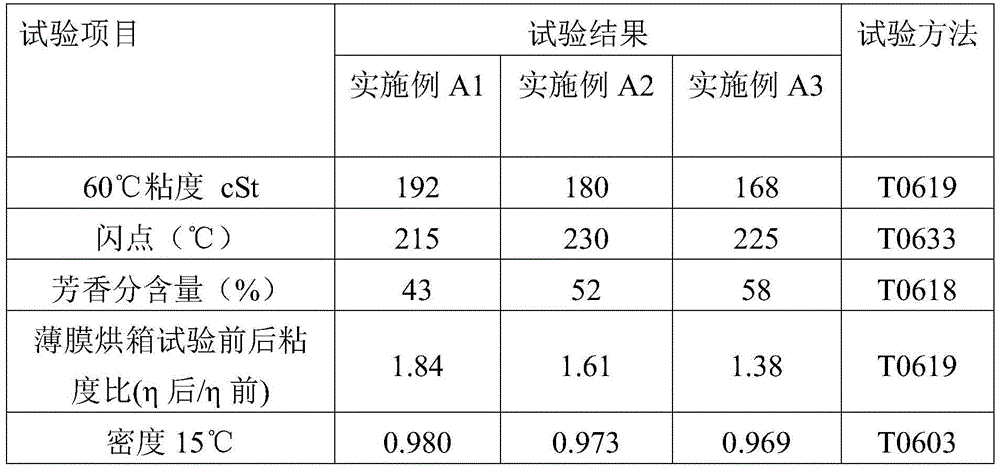

[0038] According to the corresponding test standard method, the performance of the regeneration agent for hot-in-place asphalt regeneration of the present invention is measured, and the results are shown in Table 2 below.

[0039] Table 2: Performance test results of regenerant for hot-in-place re...

Embodiment B

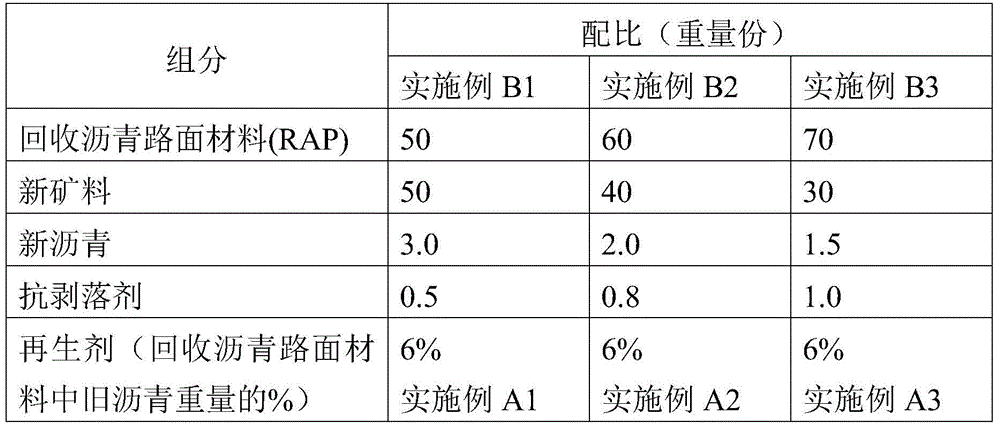

[0042] Example B: Preparation of hot-in-place recycled asphalt mixture

[0043]Mix new mineral material, new asphalt, and anti-stripping agent to obtain a new mixture, and the temperature of the new mixture on site is controlled at 140-160°C.

[0044] Pavement pretreatment. Use forest fire extinguishers to blow off the floating dust on the secondary asphalt pavement that meets the design requirements of hot-in-place regeneration.

[0045] Milling of old asphalt road. A large area of asphalt pavement is continuously heated by an asphalt pavement thermal regeneration heating machine, so that the average temperature of the pavement is higher than 120°C, which meets the requirements of the regeneration construction process and ensures that the aggregate will not be broken during plowing. Heating the milling machine, milling the old asphalt pavement and spraying the regeneration agent at the same time, stirring and loosening the old asphalt pavement with the milling machine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com