Dry desulfurization, denitration and dust removal device and method for low-sulfur flue gas in cement kiln tail

A dry desulfurization, denitration and dust removal technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high operation and maintenance costs, high fire risks, and technical difficulties of denitrification devices, and achieve obvious technical and Economical application advantages, low overall investment and operating costs, and the effect of reducing filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

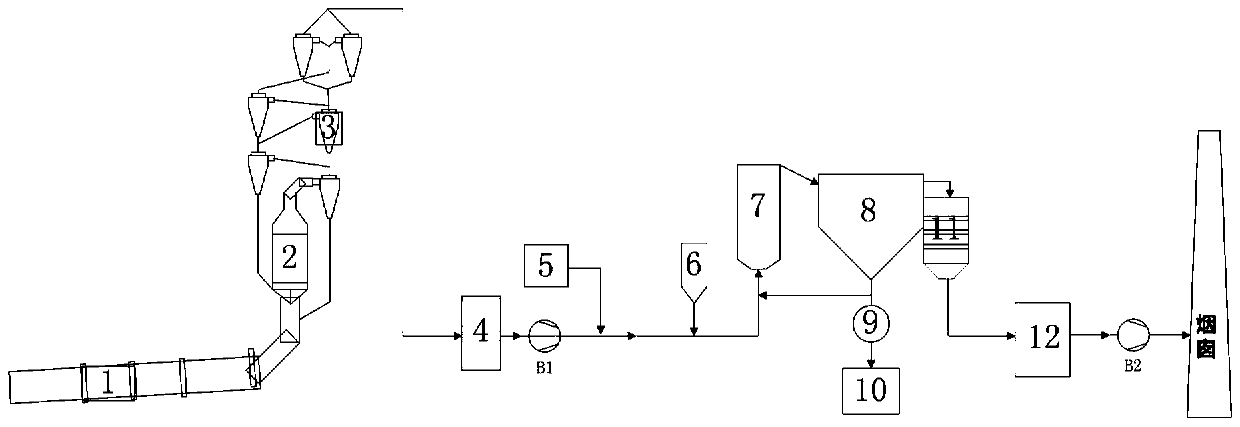

[0076] The schematic diagram of the structure of the low-sulfur flue gas dry desulfurization, denitrification and dust removal device at the cement kiln tail provided by the embodiment of the present invention can be found in figure 1 As shown; among them, 1 is a cement kiln, 2 is a calciner, 3 is a suspension preheater, 4 is a waste heat boiler, B1 is a high-temperature fan, 5 is a raw meal mill, 6 is a desulfurizer warehouse, and 7 is a low-density low-bed Circulating fluidized bed dry desulfurization tower with no water spraying on the first floor, 8 is a bag filter, 9 is a pneumatic conveying warehouse pump, 10 is a raw material storage, 11 is a medium temperature SCR denitrification device, 12 is a waste heat boiler, and B2 is an induced draft fan.

[0077] The connection relationship of the dry desulfurization, denitrification and dust removal device is specifically: the gas outlet of the cement kiln (1) is connected to the air inlet of the calciner (2), and the gas outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com