Environmentally-friendly and energy-saving processing method of blast furnace slag and special processing equipment

A technology for blast furnace slag and processing equipment, which is applied in the field of blast furnace or submerged arc furnace slag processing, which can solve the problems of large area, failure to meet low-temperature power generation requirements, and difficult control of the temperature of residual hot water after flushing slag, so as to reduce the filtration area , Reduce equipment cost and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

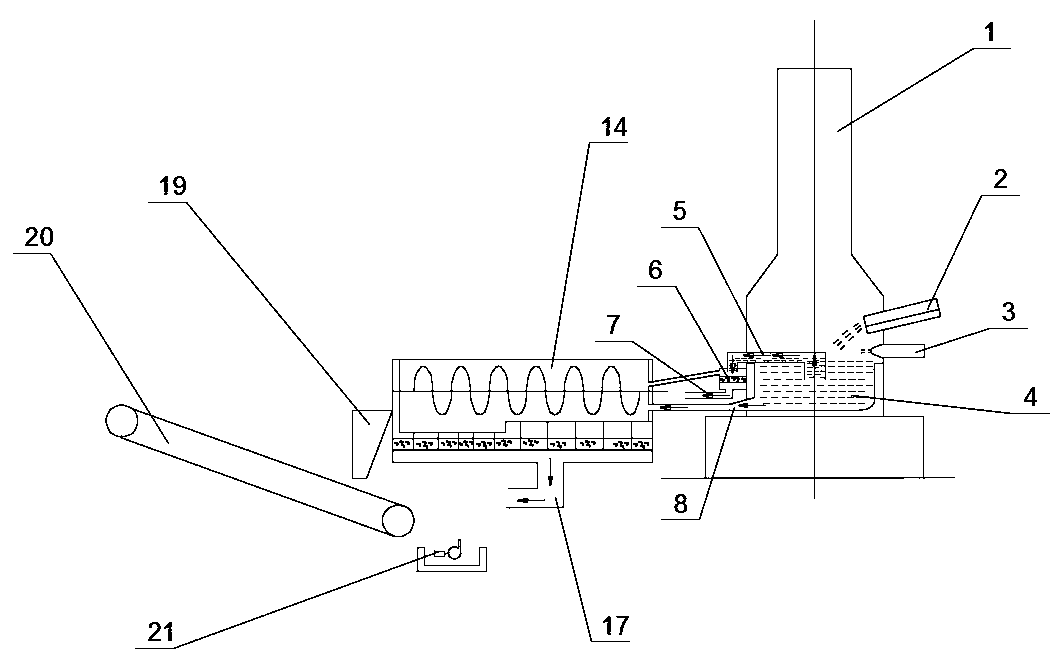

[0026] An environment-friendly and energy-saving treatment equipment for blast furnace slag, comprising a swirling water-saving granulation tower 1, a water slag propulsion conveying device 13, a water filter slag filter 14, a feeding chute 19, an inclined belt conveyor 20, and a sewage slurry pump 21 and the backwater and backwashing system; the water slag propulsion conveying device 13 is arranged in the water filter slag 14, and the slag-water mixture outlet 8 of the swirling water-saving granulation tower 1 is connected with the water filter 14, and the water filter slag The device 14 is connected to the inclined belt conveyor 20 through the discharge chute 19, and is equipped with a sewage slurry pump 21 and a backwater and backwashing system;

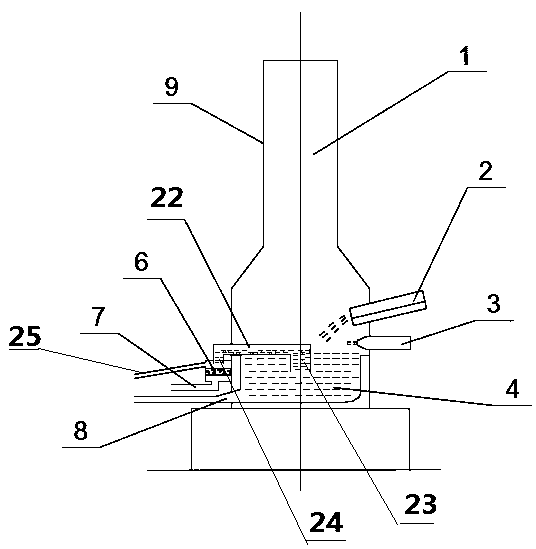

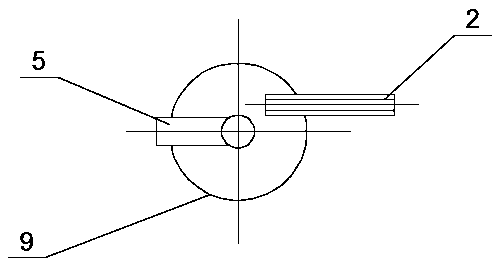

[0027] The swirling water-saving granulation tower includes a granulation tower pool 4, a granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com