Fixed plate frame microfiltration device

A fixed plate and filter technology, which is applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve the problems of floor area, installed power cost, maintenance cost and operation cost, etc., and achieve compact structure , high efficiency and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

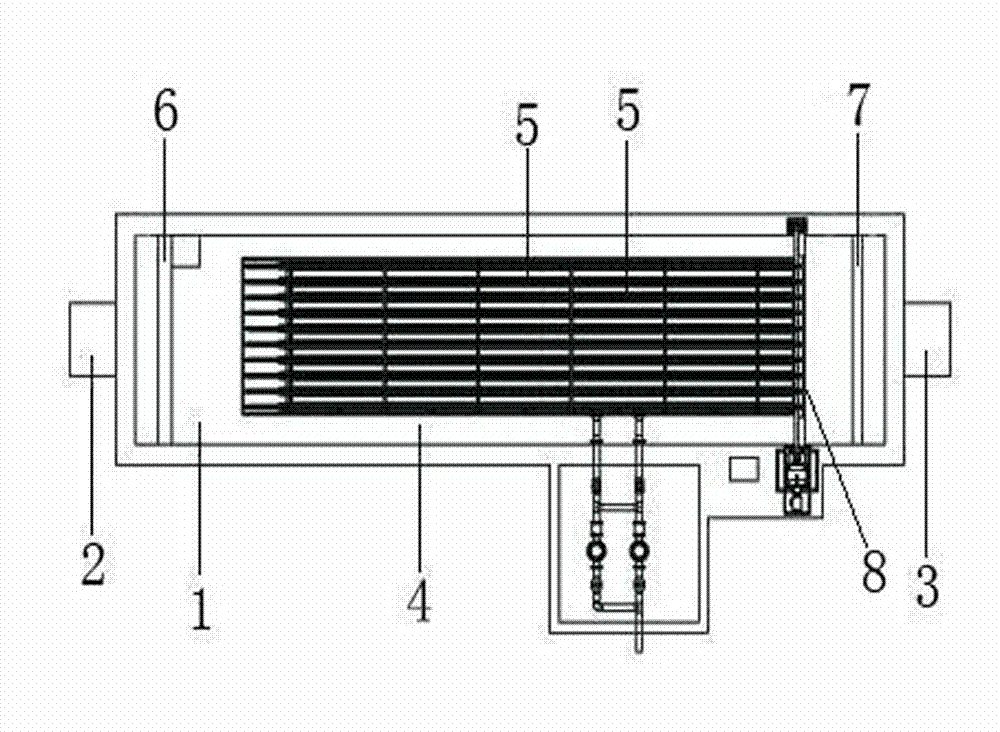

[0029] Such as figure 1 A fixed plate and frame microfiltration device shown includes a filter tank 1, an inlet pipe 2, an outlet pipe 3 and a square filter frame 4, a water distribution weir 6, an outlet weir 7, an isolation dam 8, an inlet pipe 2 and a square filter frame 4. The water outlet pipes 3 are arranged outside the two ends of the filter tank 1 respectively, and the filter frame body 4 is located in the filter tank 1. The filter frame body 4 is composed of nine square filter plates 5, which are arranged in parallel and at intervals, and the outer layer of the filter plate Wrapped with fiber microfiltration cloth, a water distribution weir 6 is arranged between the water inlet pipe 2 and the filter frame 4. The water distribution weir 6 is located inside the filter tank 1, close to the water inlet pipe 2, and close to the water outlet pipe 3. A water outlet weir 7 is arranged inside the filter tank 1 on one side, and an isolation dam 8 is also arranged between the wa...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, the difference is that a slot that can be matched with the filter plate 5 is provided at the bottom of the filter tank 1, and the filter plate 5 is fixed in the filter tank through the slot, which facilitates the filtering of the filter plate. , Replacement and removal of filter cloth.

Embodiment 3

[0034] This embodiment is basically the same as Embodiment 2, the difference is that in this embodiment, support brackets are set in the gaps between the square filter plates 5, and cleaning tips are added to the support brackets, so as to facilitate instant cleaning of the filter plates on site. cloth without removing the filter cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com