Compression ignition internal-combustion engine system adopting carbinol-group fuel and operation method thereof

An internal combustion engine, methanol-based technology, which is applied to internal combustion piston engines, combustion engines, chemical instruments and methods, etc., can solve the problems of methanol-based fuels with low cetane number and cannot be directly compressed and burned, so as to improve heat utilization efficiency and maintain power. performance, the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

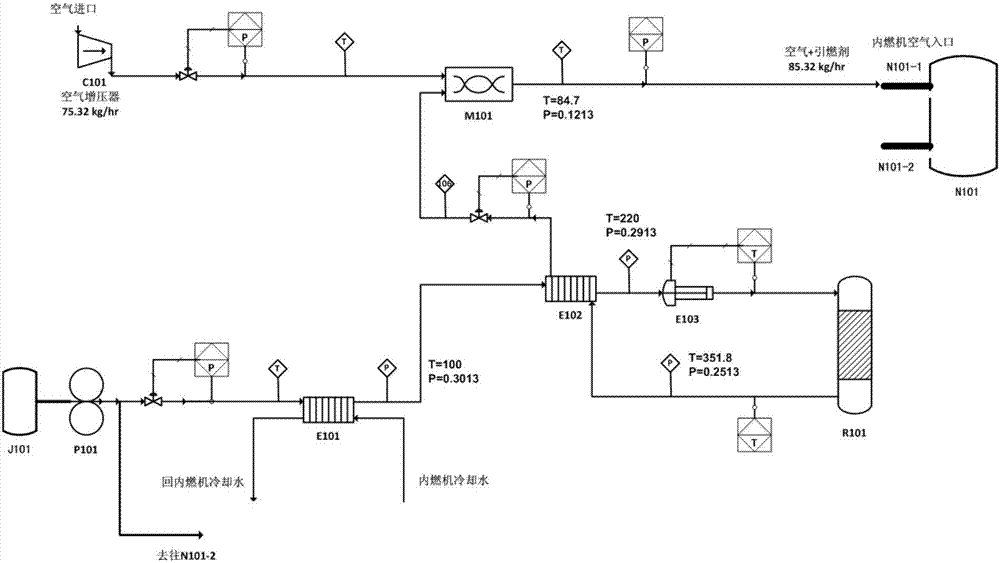

[0035] Embodiment: The internal combustion engine 1 of the present invention repeats the cycle according to the intake stroke, compression stroke, combustion stroke and exhaust stroke;

[0036] In the case of a cold start, the fuel pump P101 pumps methanol-based fuel from the fuel tank J101, and divides the methanol-based fuel into two paths, where the first methanol-based fuel accounts for the total flow of the pumped methanol-based fuel 90-95% of the fuel is used as fuel to the fuel inlet N101-2 of the compression-ignition internal combustion engine N101; the second methanol-based fuel accounts for 5-10% of the total methanol-based fuel pumped out, and then the electric heater E103 Under heating, make the methanol temperature reach the optimal reactor feed temperature in the range of 200-250℃, for example, 220℃, the pressure is 0.2913MPa, and then enter the igniter online preparation device R101, under the action of the catalyst, the methanol is converted into dimethylform Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com