Roof and container with the same

A technology of top cover and cover plate, which is applied in the field of containers, can solve the problems of reducing the anti-corrosion performance and service life of the top cover, affecting the operability of the box body by the metal top cover, and increasing the difficulty of the operator's work, so as to improve the service life and facilitate the operation. Operation, the effect of excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

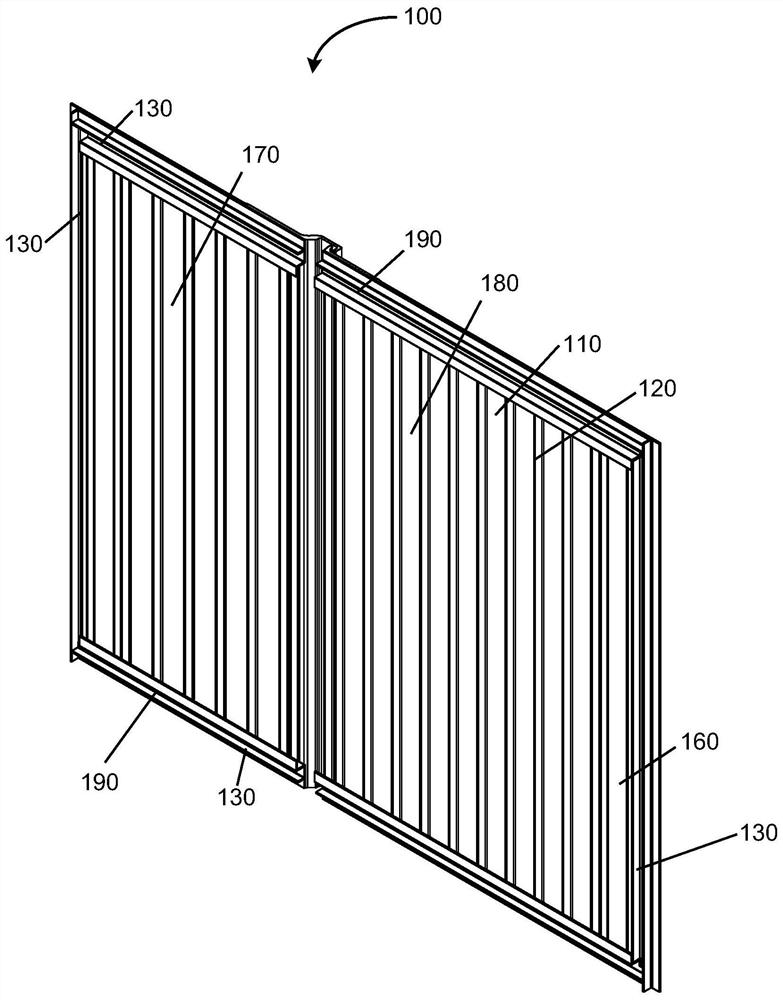

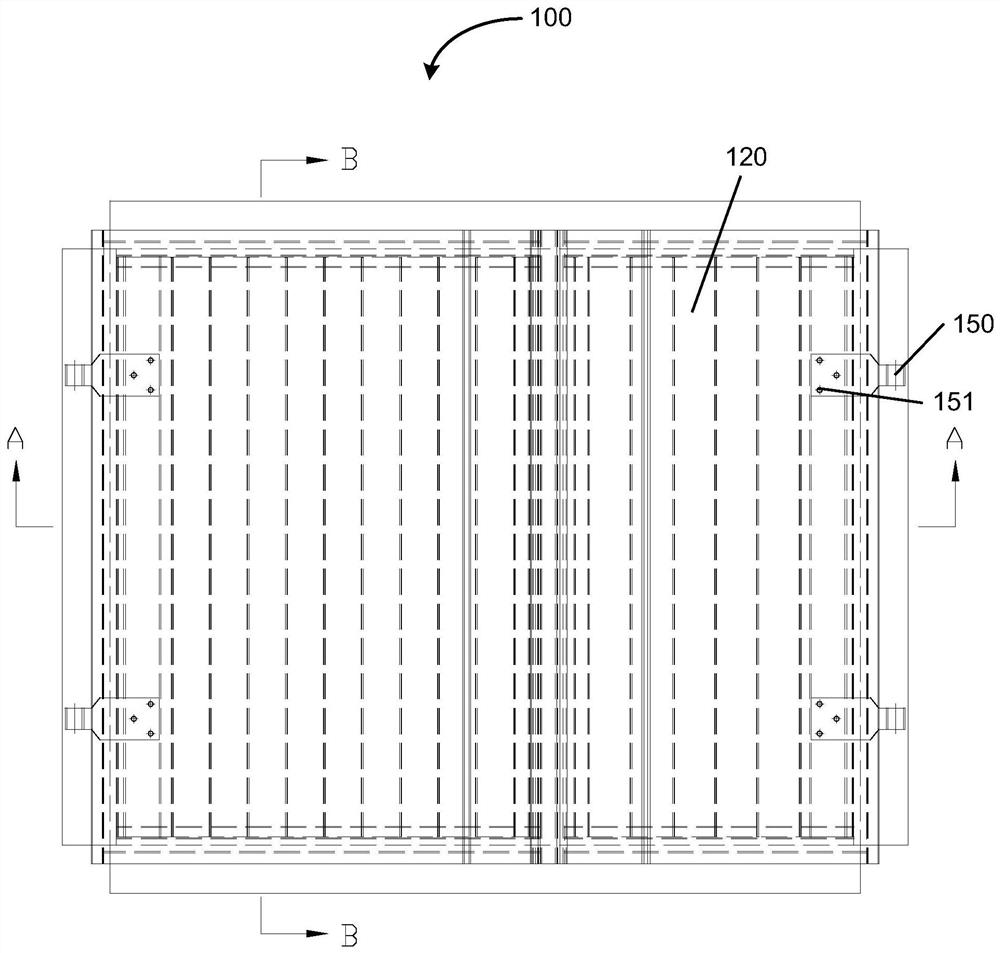

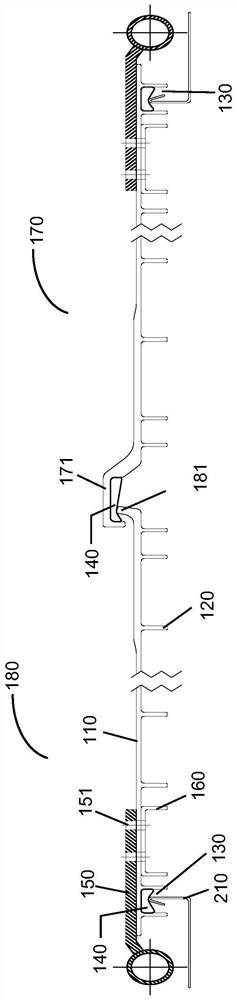

[0056] The invention provides a top cover, such as figure 1 shown. It can be understood that the top cover can be applied to various containers and various boxes in vehicles or other transportation fields, especially suitable for dry bulk containers.

[0057] The roof according to the invention is made of fiber-reinforced composite material. Fiber-reinforced composite material is a high-performance product prepared by a certain molding process with fiber as the reinforcing material and resin as the matrix material. It has excellent mechanical properties, anti-corrosion properties and weight-loss properties. The roof made of fiber-reinforced composite material can effectively extend the service life and provide customers with added value.

[0058] Specifically, the top cover according to the present invention mainly uses one or more of materials such as glass fiber, basalt fiber, carbon fiber, aramid fiber, and other natural fibers as reinforcements, and uses unsaturated poly...

Embodiment approach 2

[0097] Refer to the following Figure 14-15 A second preferred embodiment of the present invention will be described. Figure 14-15 is a schematic diagram according to the second preferred embodiment of the present invention. Such as Figure 14-15 As shown, the top cover 200 has substantially the same configuration as the top cover 100 . Thus, structures having substantially the same functions as those in the first embodiment will not be described in detail here for the sake of brevity.

[0098] Such as Figure 14 As shown, the top cover 200 includes a top cover cover plate 210 and a cover reinforcement plate 220 . The cover body reinforcing plate 220 is vertically arranged on the lower surface of the roof cover plate 210, and extends on the lower surface of the entire roof cover plate 210 in the width direction and the length direction of the entire roof cover plate 210, that is, covers The body reinforcement boards 220 are arranged in a criss-cross pattern on the roof c...

Embodiment approach 3

[0102] Refer to the following Figure 16-20 A third preferred embodiment of the present invention will be described. Figure 16-20 is a schematic diagram according to the third preferred embodiment of the present invention. Here, structures having substantially the same functions as those in the first embodiment are omitted for brevity.

[0103] Such as Figure 16 As shown, the top cover 300 includes a top cover cover plate 310 and a plurality of cover reinforcement plates 320 . In the present embodiment, the cover reinforcement plate 320 is configured as a protrusion protruding from the surface of the top cover cover plate 310 . A plurality of cover reinforcement plates 320 are arranged on the surface of the roof cover plate 310 and extend over the entire surface of the roof cover plate 310 in the width direction of the entire roof cover plate 310 such that the plurality of cover body reinforcement plates 320 are integrally connected to form a wavy cross-sectional structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com