A methanol engine system using methanol to produce hydrogen as an igniter and an operation method thereof

A methanol engine and methanol hydrogen production technology, which is applied to combustion engines, internal combustion piston engines, fuel systems, etc., can solve the problems of difficult engine start-up process and high compression ignition point temperature, and achieve the effects of reducing equipment investment, simplifying the process, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

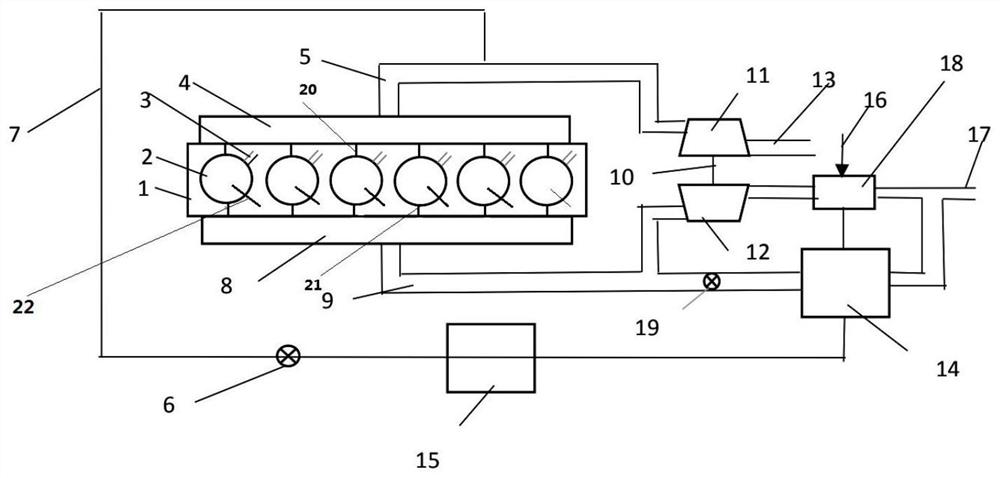

[0036] The first aspect of the present invention provides a methanol engine system using two-stage heating of methanol to produce hydrogen, which includes:

[0037] Methanol engine 1, it comprises cylinder assembly, and described cylinder assembly has cylinder 2, intake passage 20, exhaust passage 21, fuel nozzle 3, and described cylinder 2 is connected to described intake passage 20, described exhaust passage 21 and said fuel nozzle 3;

[0038] Gas supply system, which includes a methanol heater 18 with a methanol nozzle 16, a methanol hydrogen production device 14, a hydrogen storage container 15, and a hydrogen pipe 7 connected in sequence, and also includes an air intake pipe 13, a compressor 11, and an air intake pipe connected in sequence 5. The outlet of the hydrogen pipe 7 is connected to the inlet pipe 5, and the outlet of the inlet pipe 5 is connected to the inlet channel 20;

[0039] Exhaust system, which includes an exhaust pipe 9, which is divided into two exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com