Patents

Literature

31results about "Fuel systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dual fuel engine

InactiveUS20050205021A1Preventing operation of engineEasy to adaptElectrical controlInternal combustion piston enginesDiesel injectorPiston

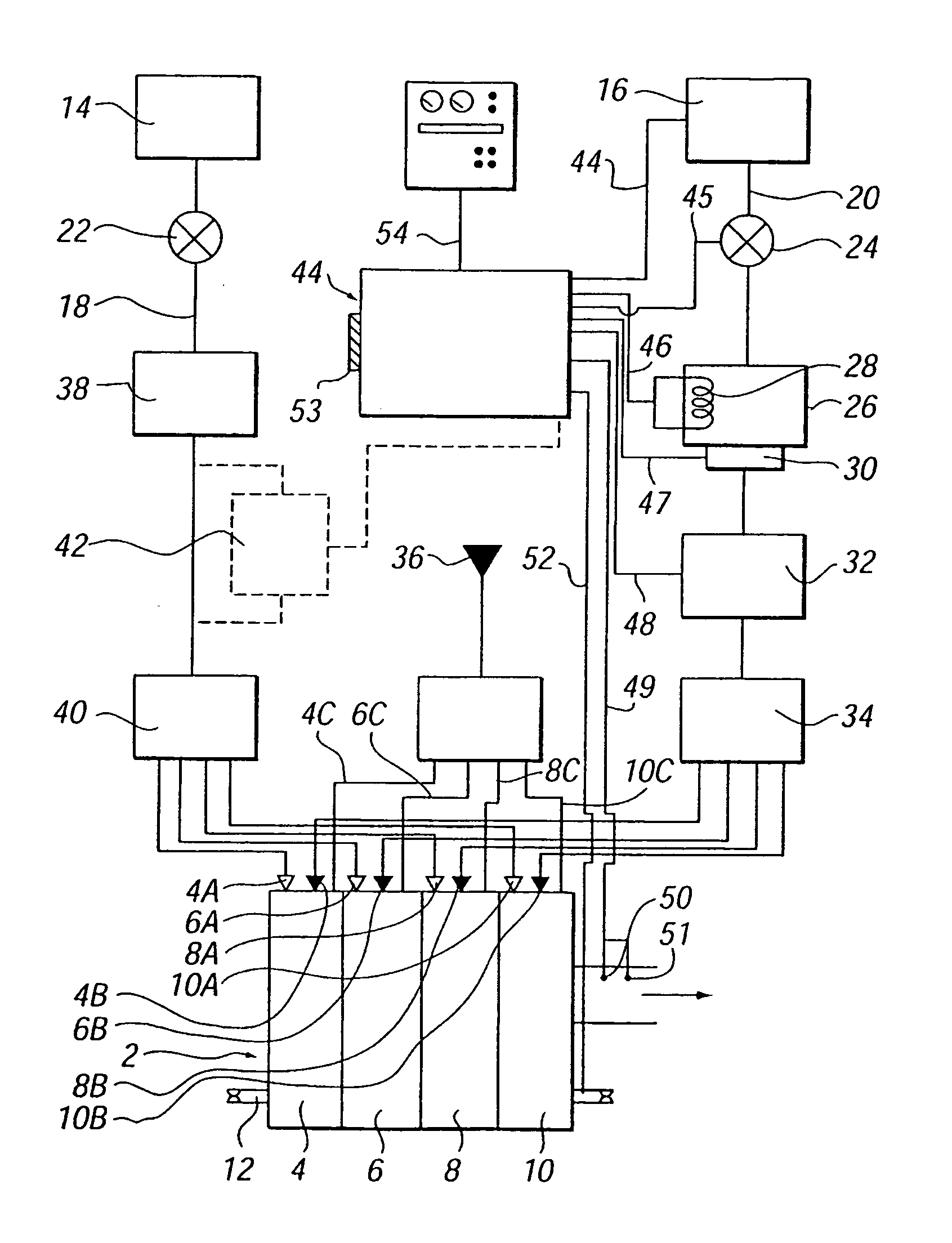

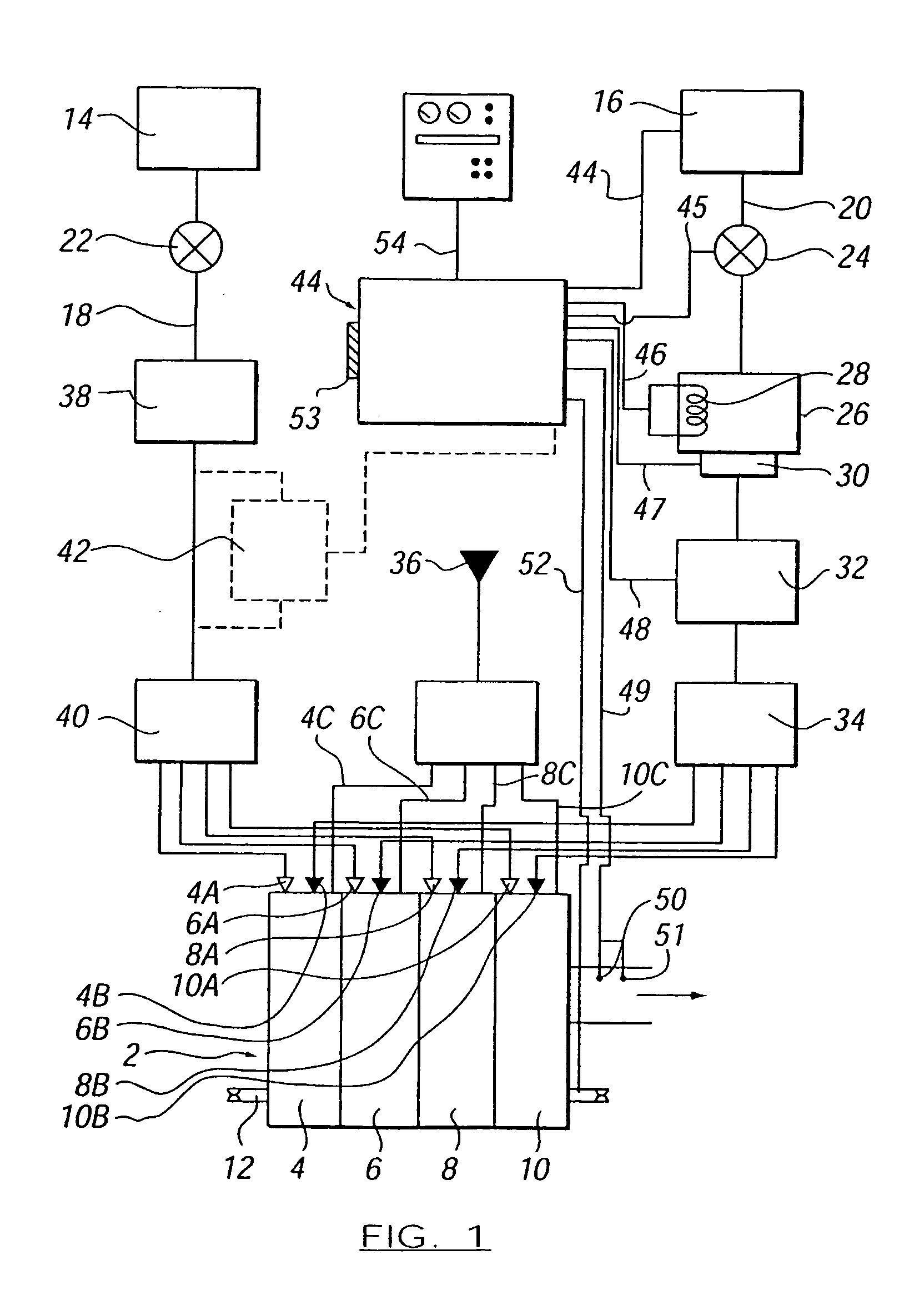

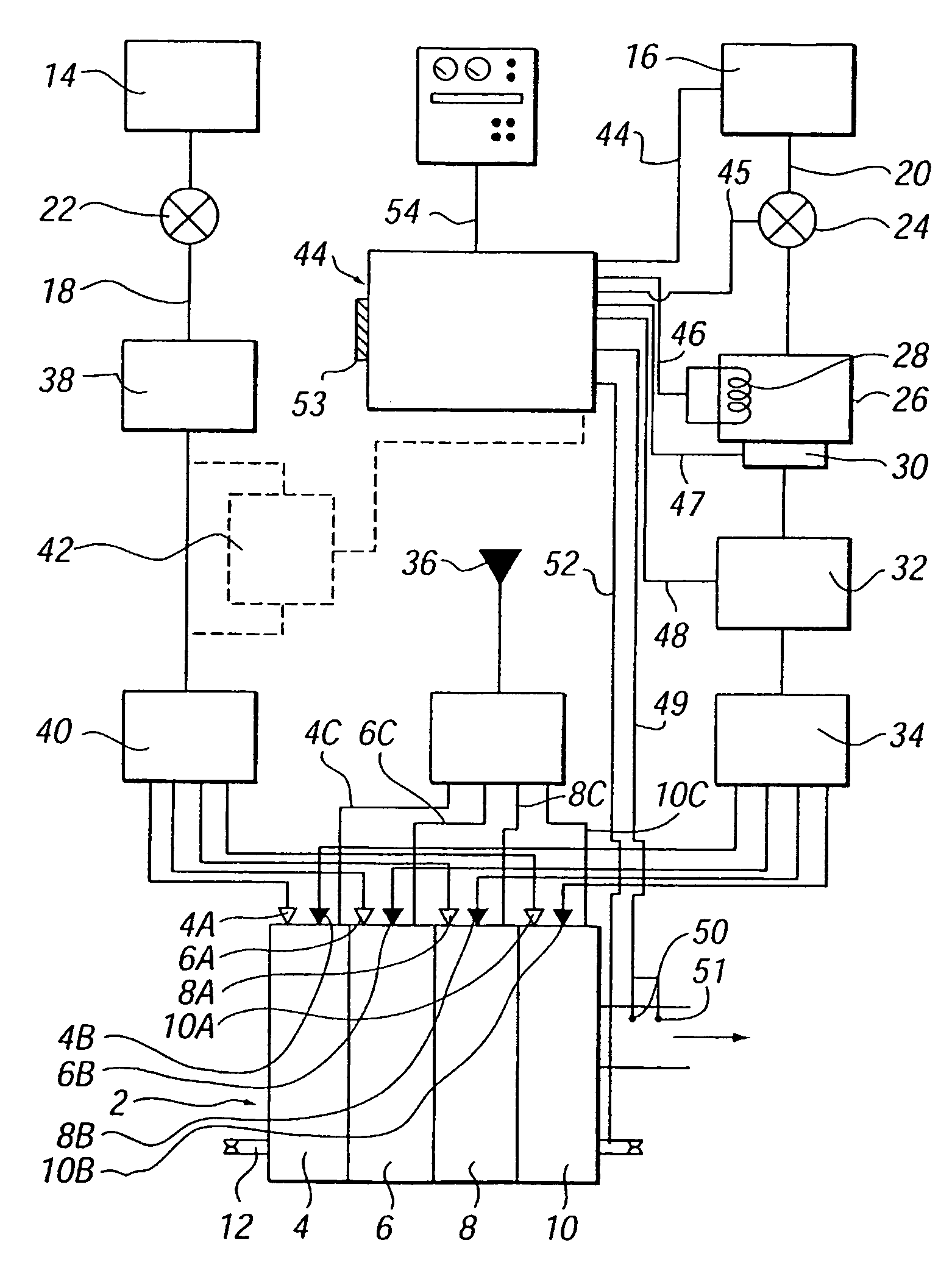

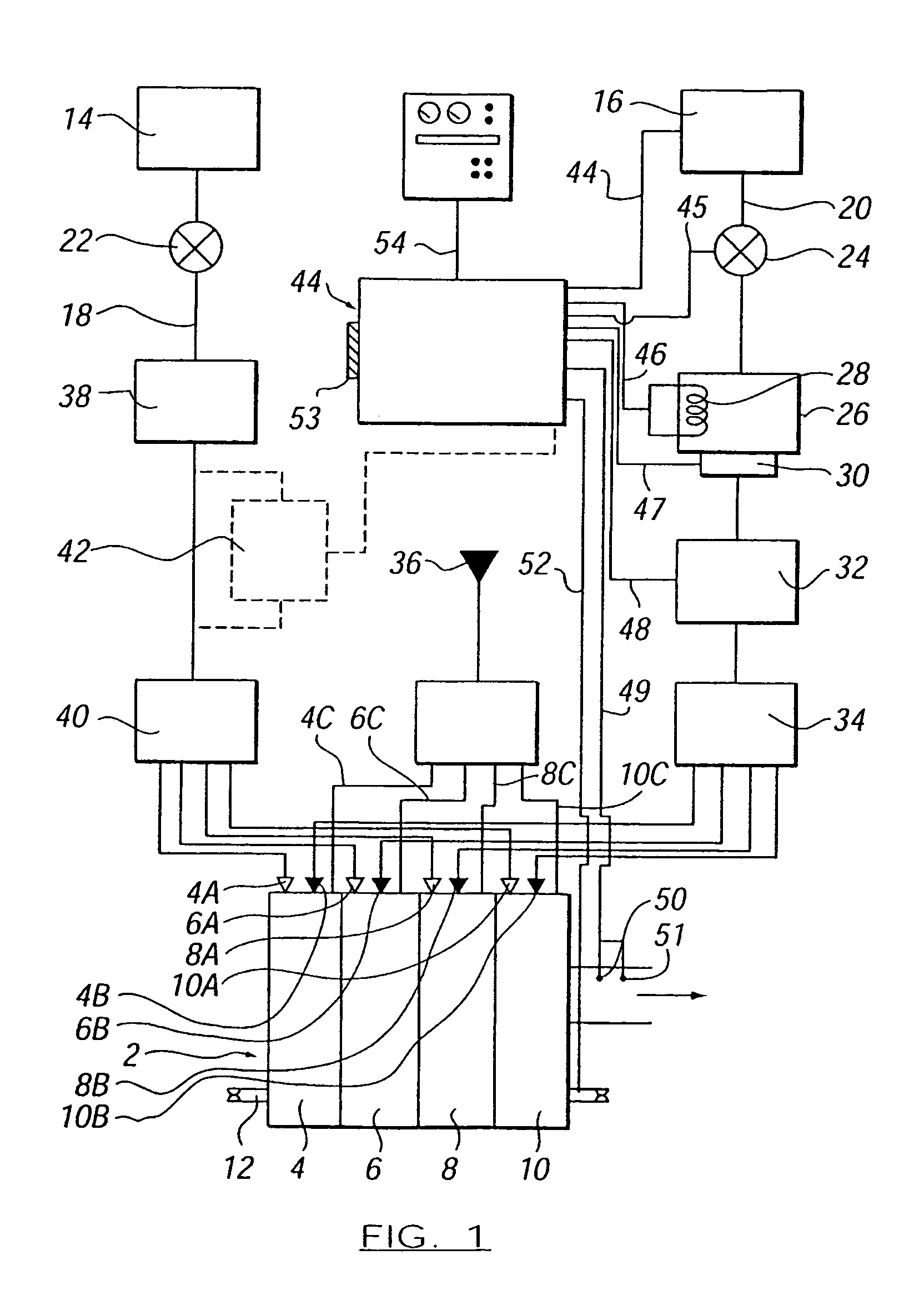

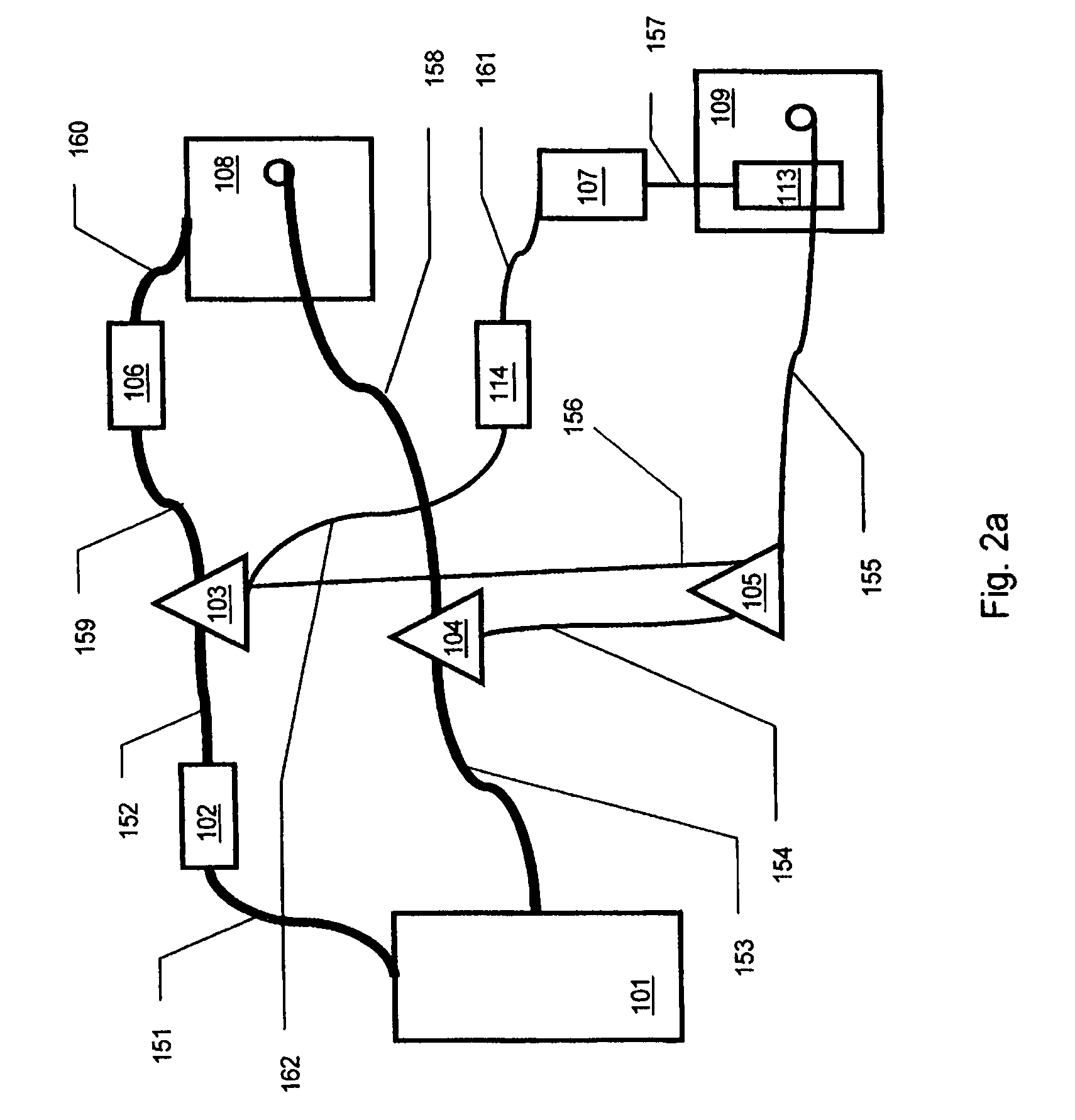

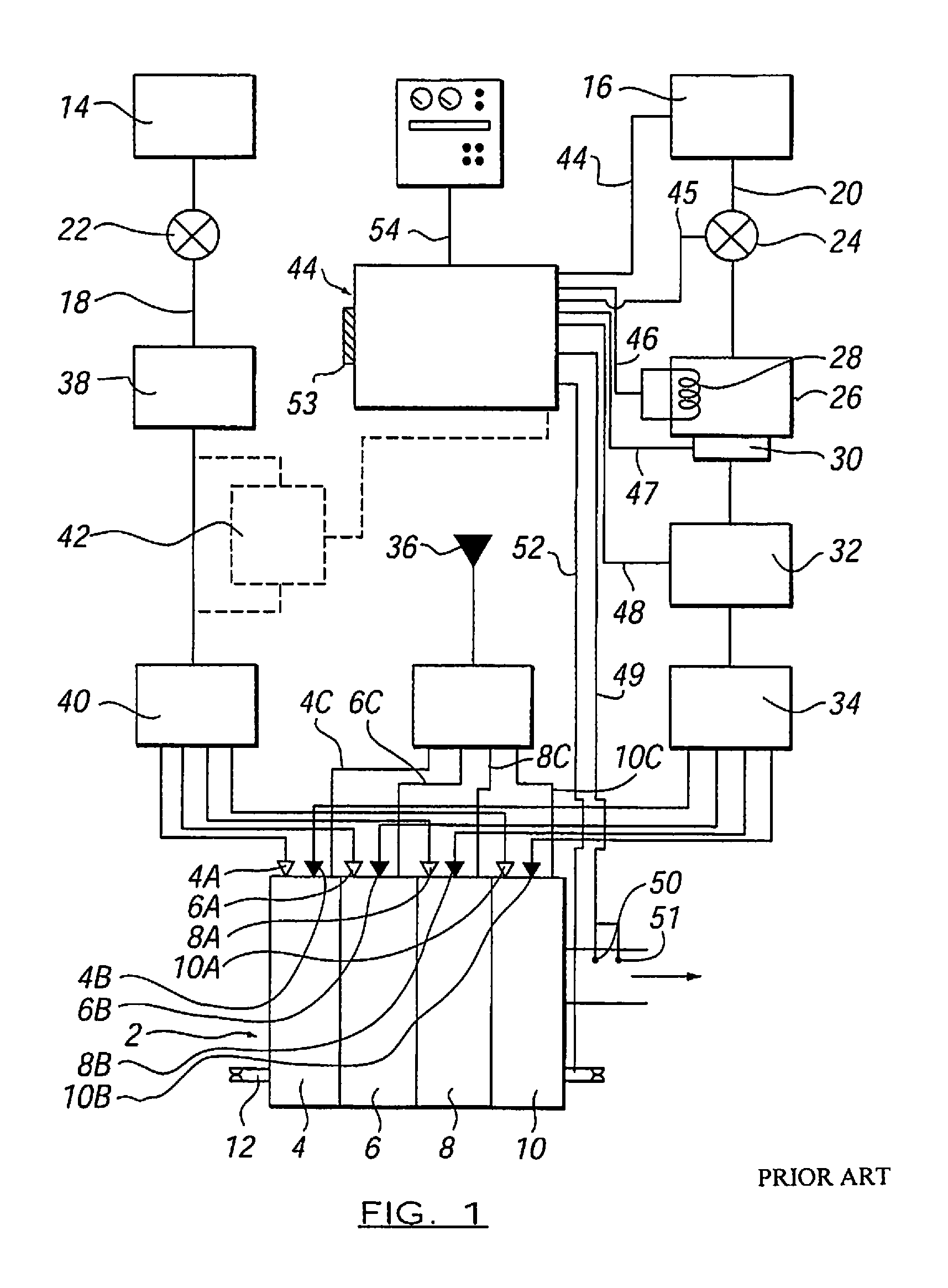

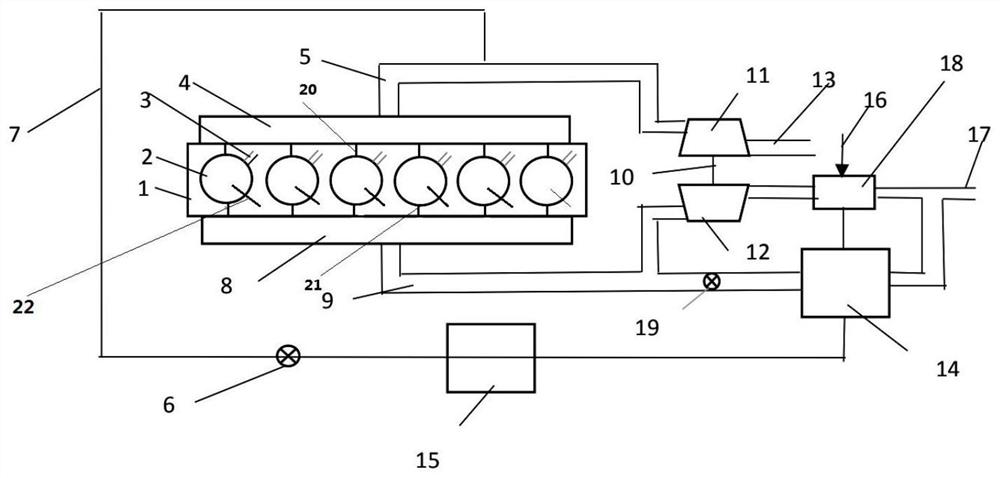

A dual fuel engine (2) is provided which is supplied with diesel fuel and at least one secondary fuel, such as LPG. The engine (2) has a plurality of cylinders (4, 6, 8, 10) in which pistons reciprocate. Each cylinder has diesel injectors (4A, 6A, 8A, 10A) for injecting the diesel fuel into the cylinder during an appropriate stroke of the piston and an air inlet valve (4C, 6C, 8C, 10C) which opens during the appropriate stroke of the piston to permit air flow therethrough. Each cylinder is further provided with LPG injectors (4B, 6B, 8B, 10B) for injecting the secondary fuel into the cylinders. The LPG injectors are independent to and separate from the diesel fuel injectors. The LPG and diesel fuel injectors are also independently controlled.

Owner:INTELLIGENT DIESEL SYST

Dual fuel engine

InactiveUS7444986B2Reduce stepsEasy to adaptElectrical controlInternal combustion piston enginesDiesel injectorPiston

A dual fuel engine (2) is provided which is supplied with diesel fuel and at least one secondary fuel, such as LPG. The engine (2) has a plurality of cylinders (4, 6, 8, 10) in which pistons reciprocate. Each cylinder has diesel injectors (4A, 6A, 8A, 10A) for injecting the diesel fuel into the cylinder during an appropriate stroke of the piston and an air inlet valve (4C, 6C, 8C, 10C) which opens during the appropriate stroke of the piston to permit air flow therethrough. Each cylinder is further provided with LPG injectors (4B, 6B, 8B, 10B) for injecting the secondary fuel into the cylinders. The LPG injectors are independent to and separate from the diesel fuel injectors. The LPG and diesel fuel injectors are also independently controlled.

Owner:INTELLIGENT DIESEL SYST

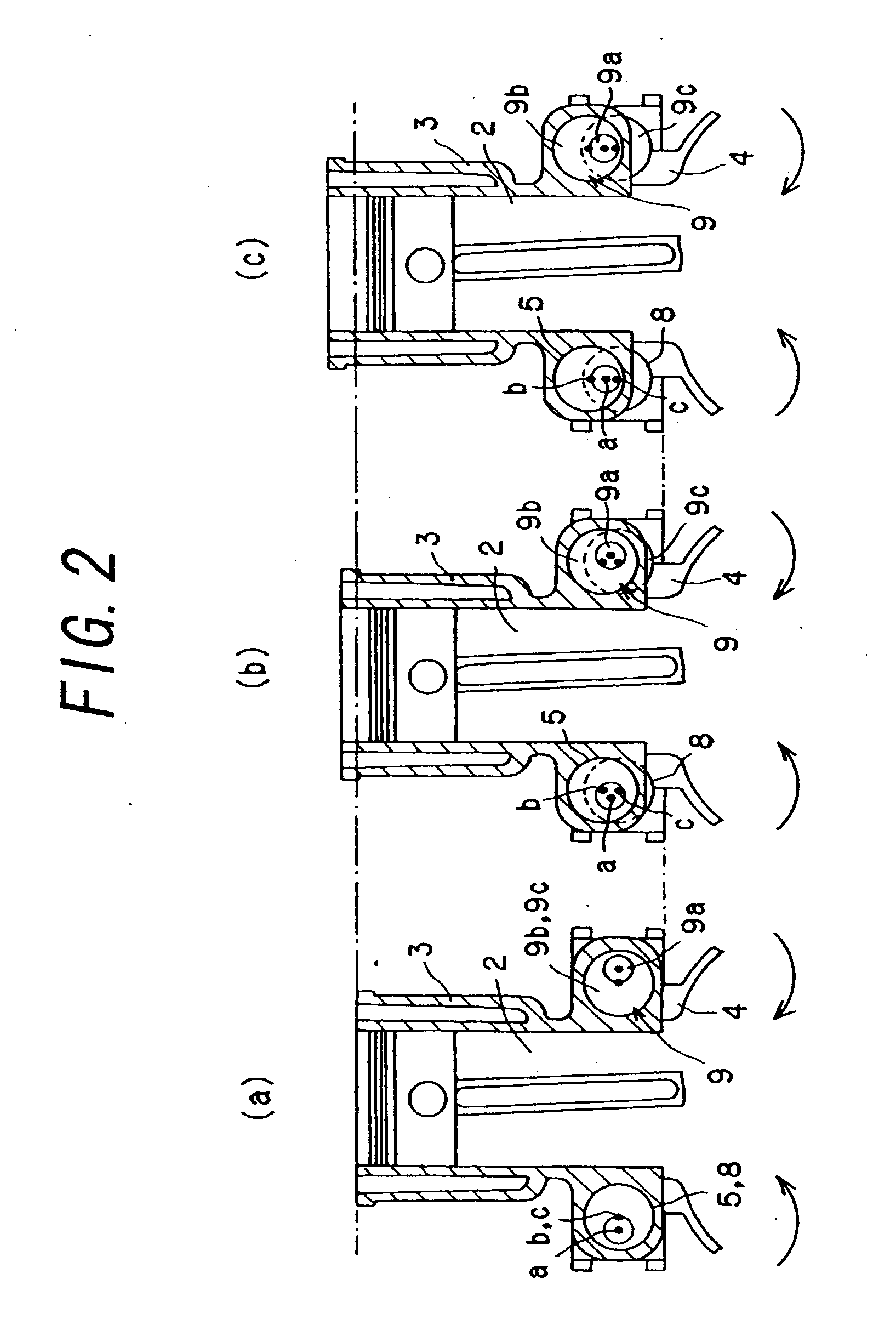

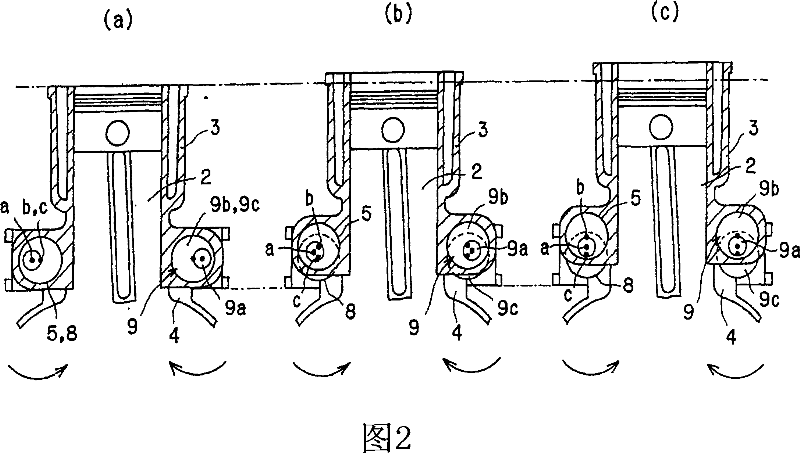

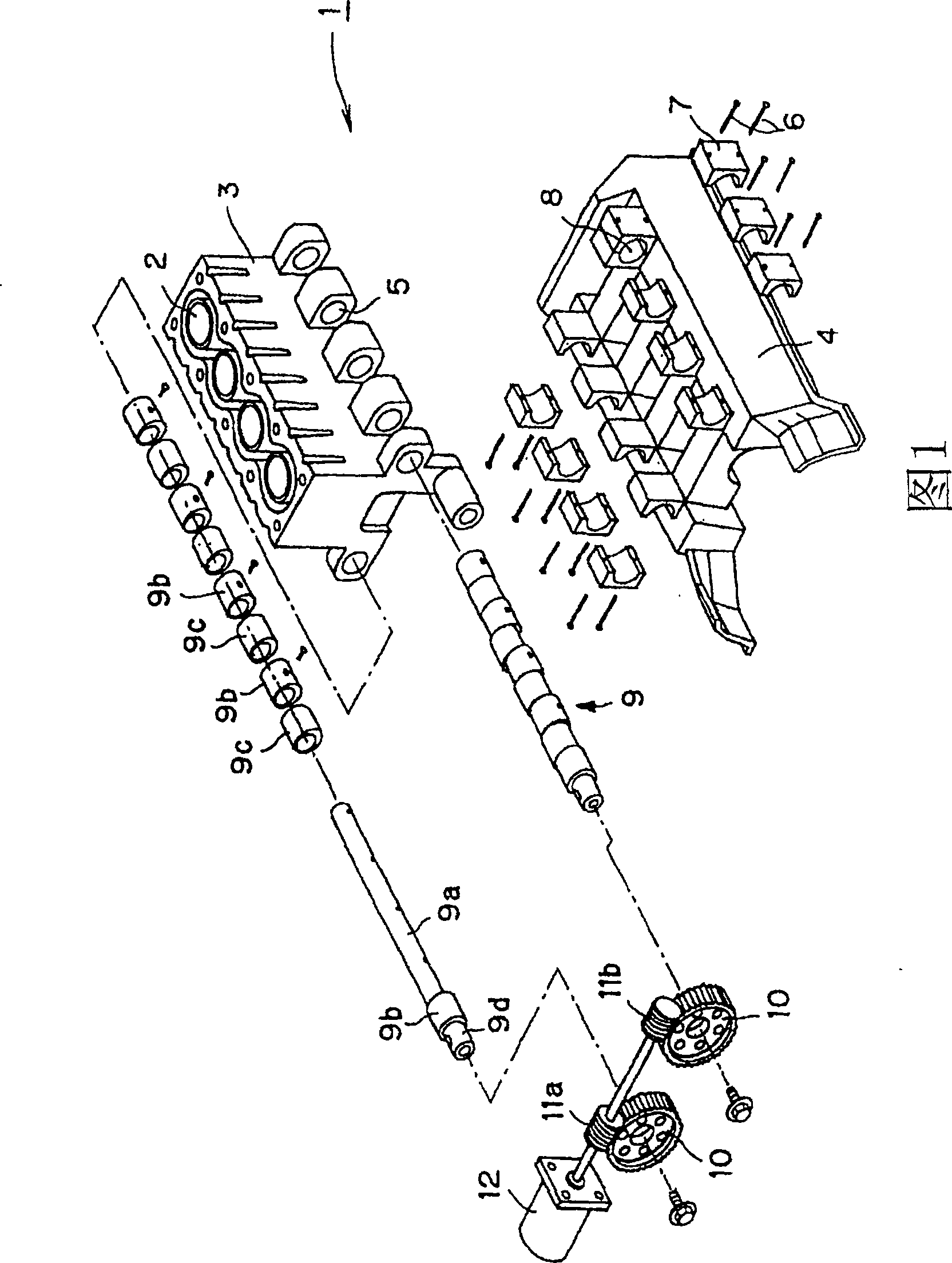

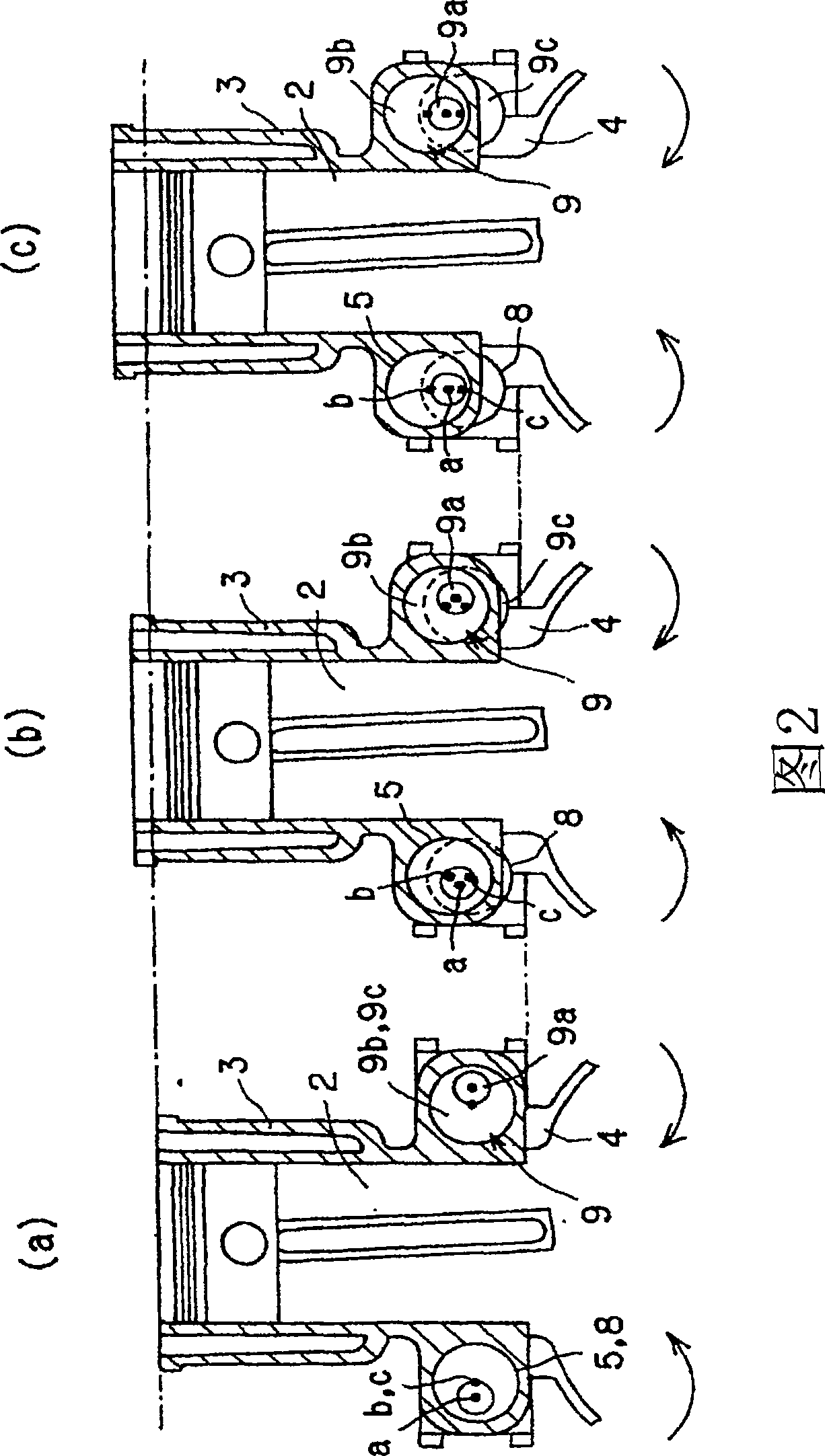

Variable Compression Ratio Internal Combustion Engine

InactiveUS20080022982A1Improve engine performanceImprove combustion efficiencyElectrical controlInternal combustion piston enginesCombustionFuel injection

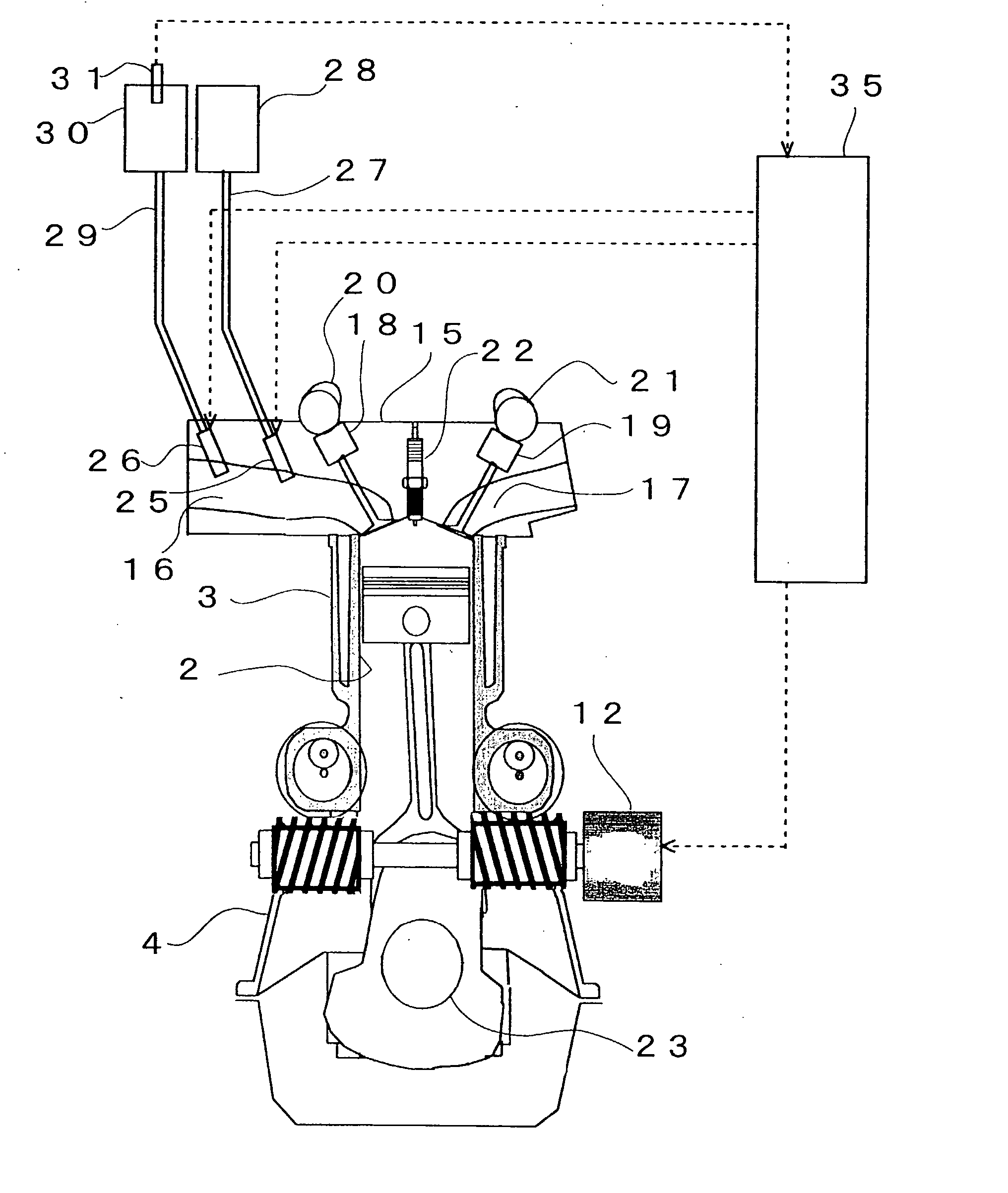

The invention is directed to a variable compression ratio internal combustion engine in which the compression ratio of the engine can be varied and multiple types of fuels having different combustion velocities are used. The invention provides a technology for achieving excellent engine performance for respective types of fuels. In the variable compression ratio internal combustion engine in which the compression ratio can be varied and multiple types of fuels having different combustion velocities are injected through multiple fuel injection valves, maps from which a target compression ratio of the internal combustion engine is read out are switched in accordance with the fuel used, thereby suppressing knocking or other disadvantages.

Owner:TOYOTA JIDOSHA KK

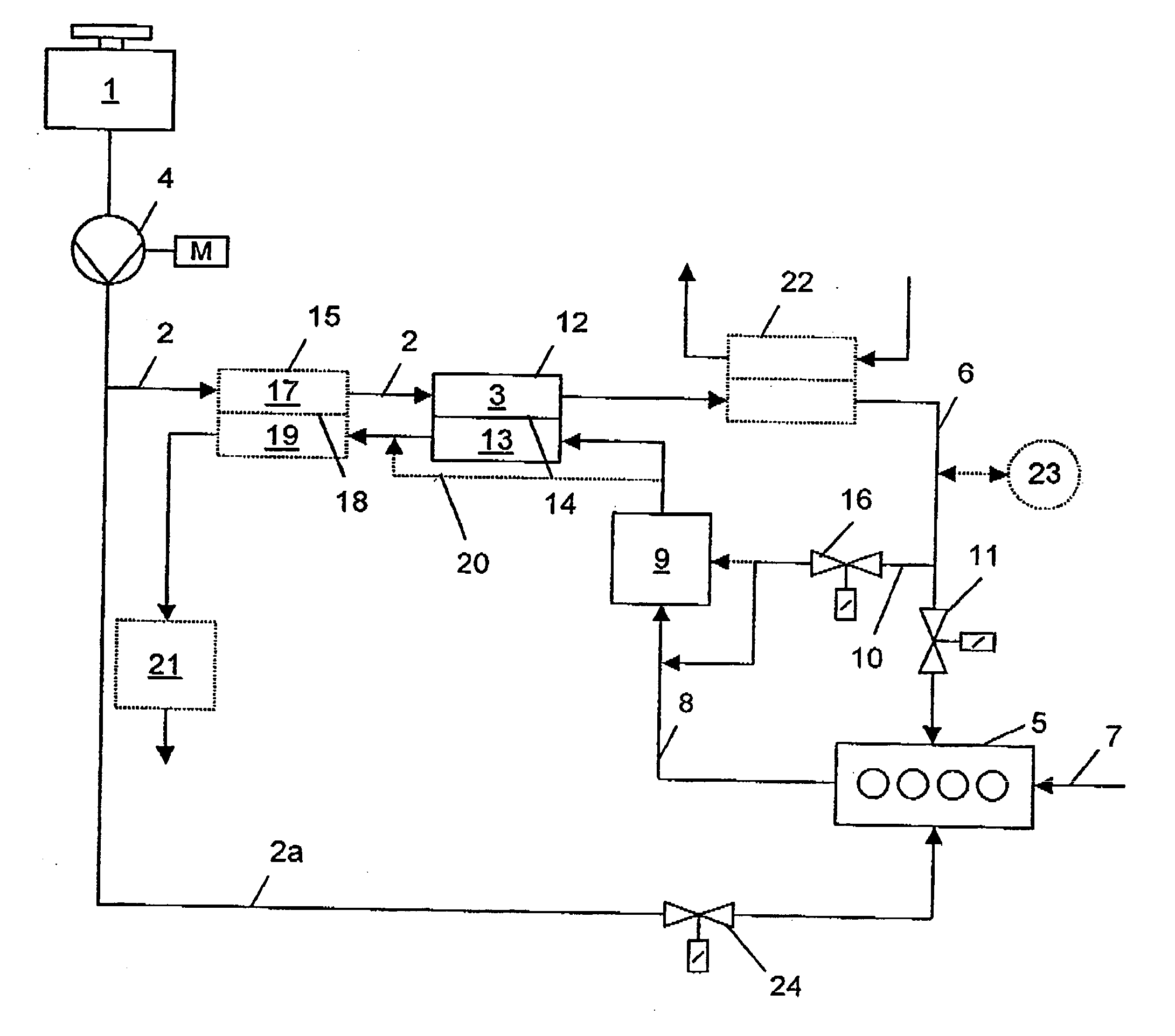

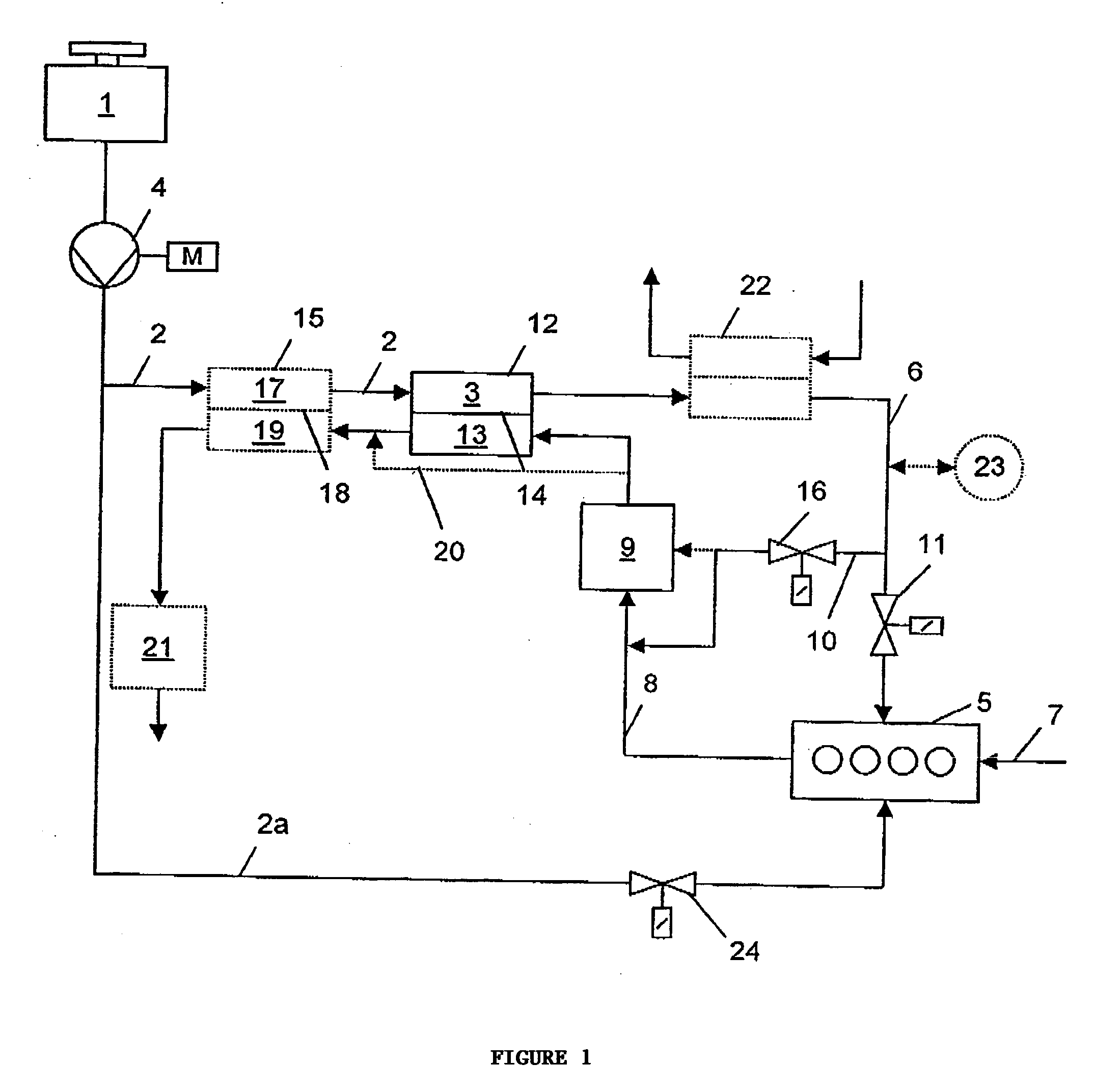

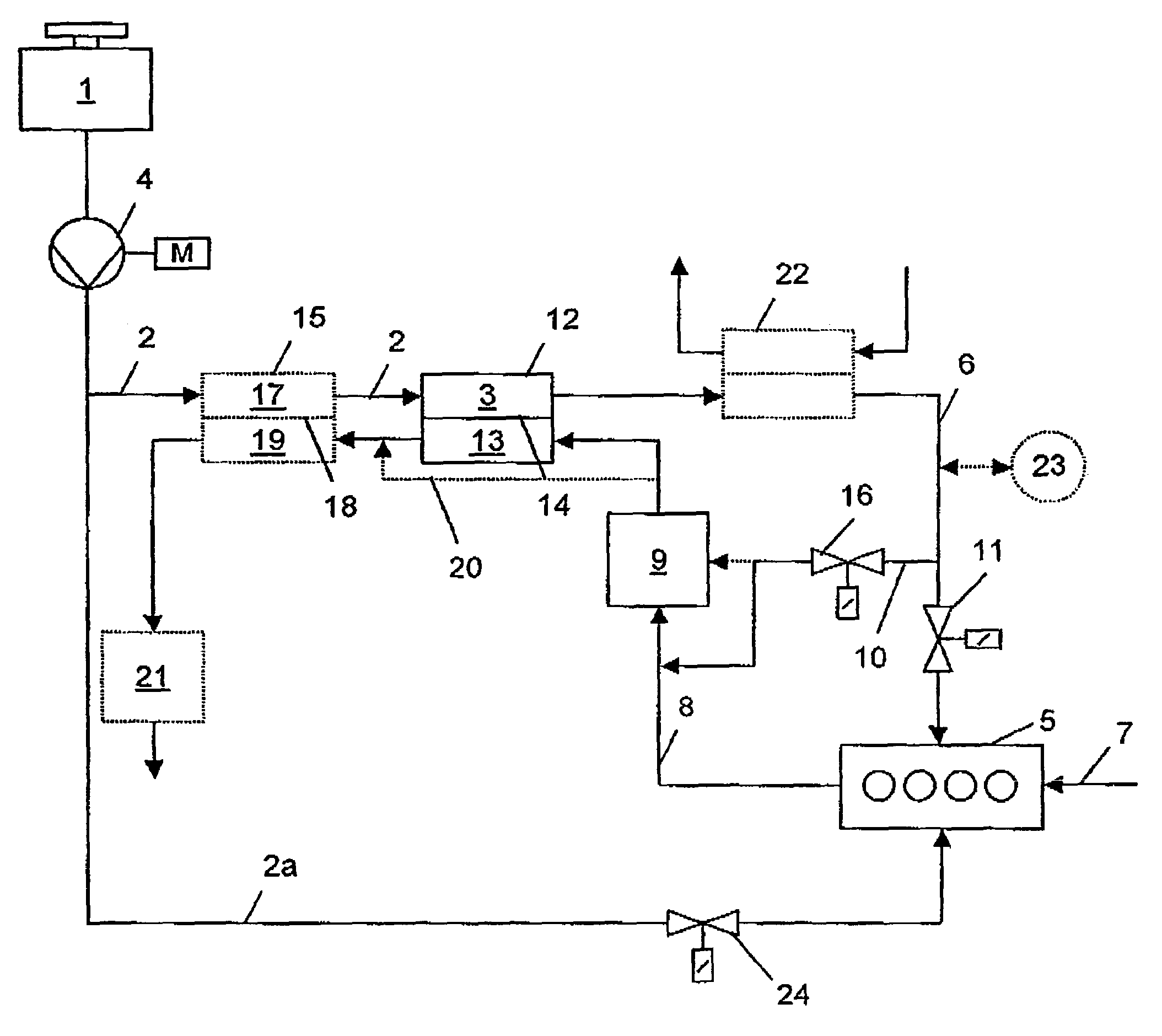

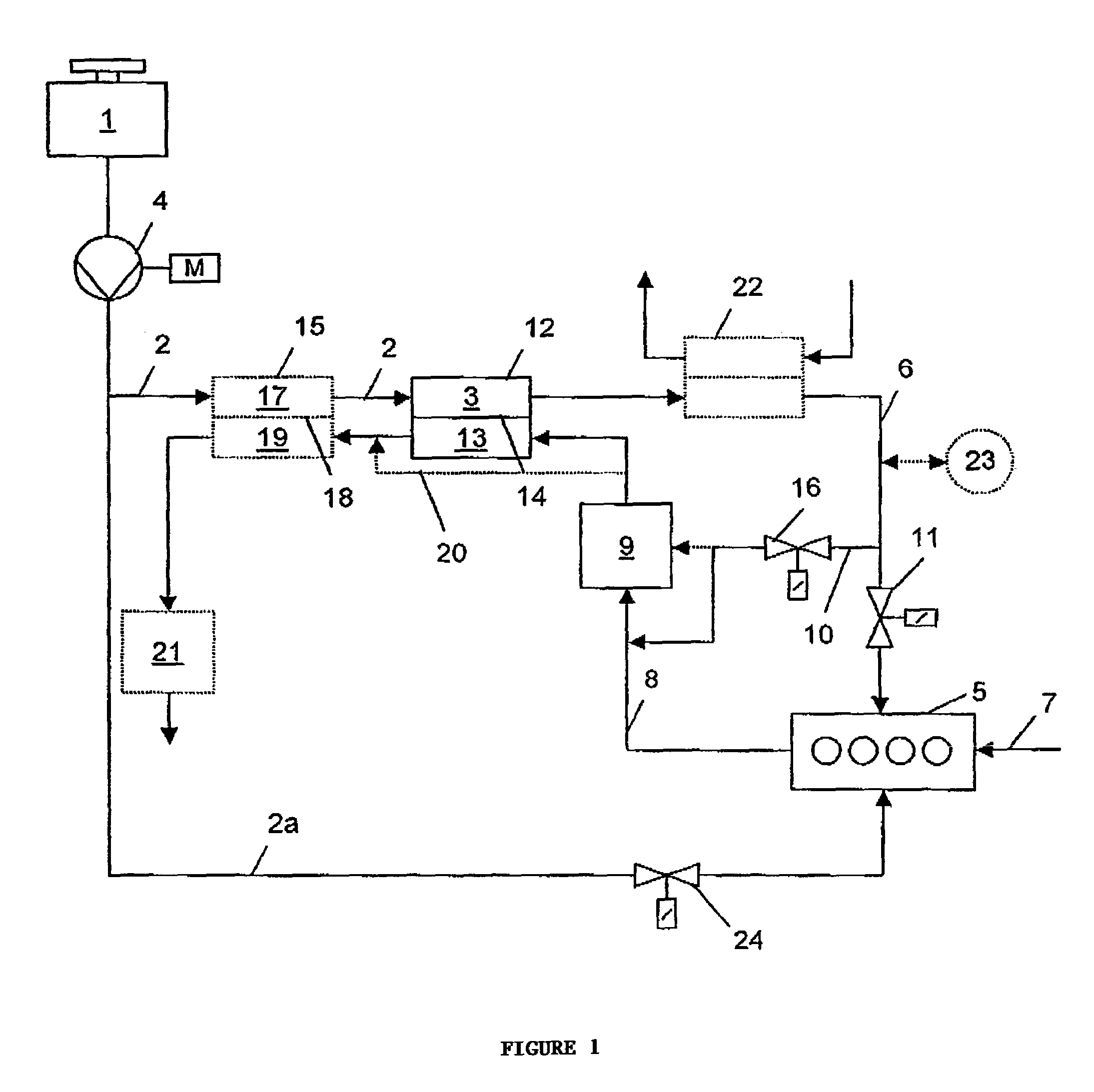

Internal combustion engine fuel supply system

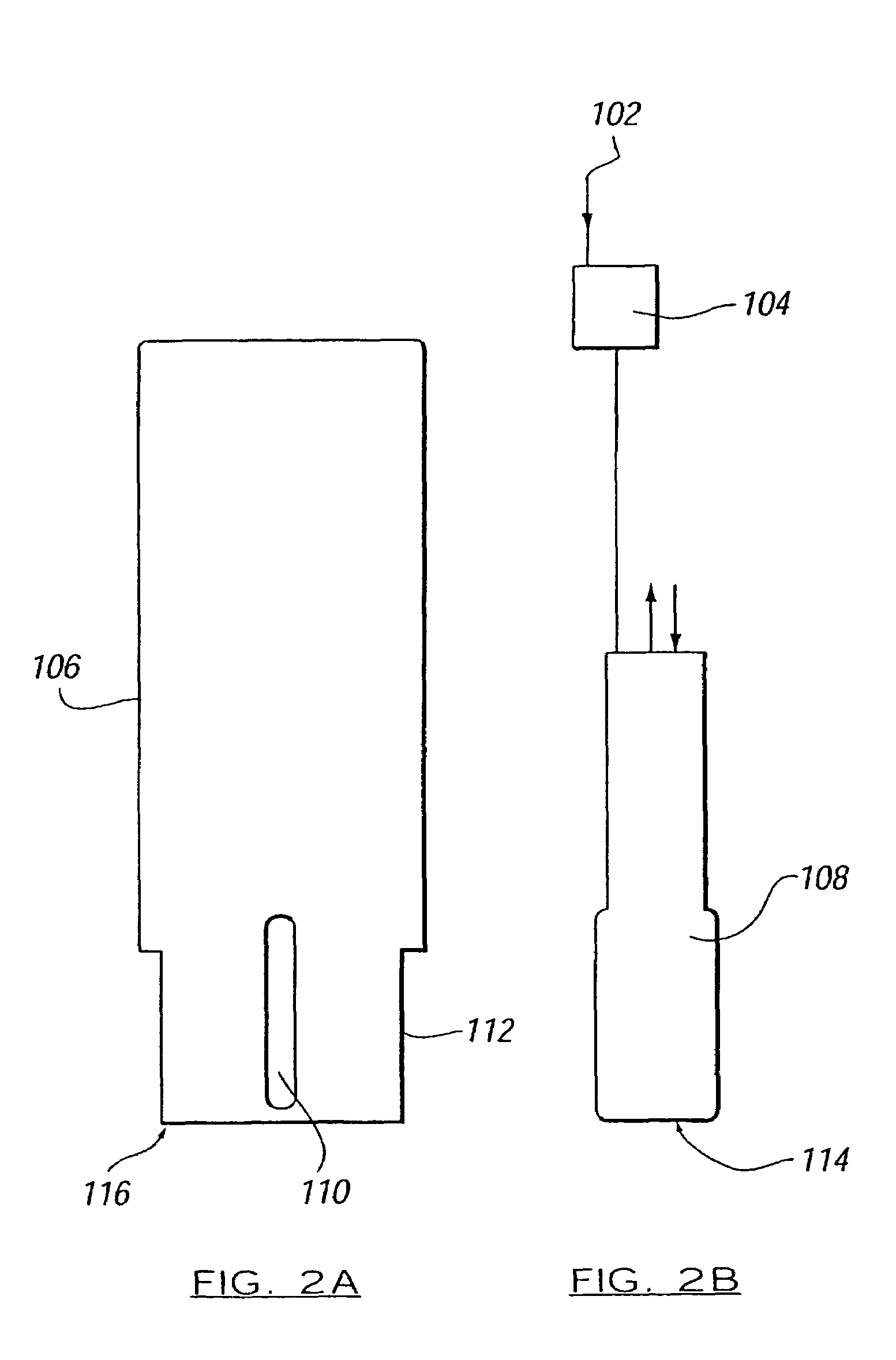

InactiveUS20060059897A1Reduce nitrogen oxide contentHigh calorific valueInternal combustion piston enginesExhaust apparatusThermal energyHydrogen

A system to supply hydrogen-rich fuel to an internal combustion engine, whereby a hydrogen-rich gas is produced from a liquid raw fuel by a hydrogen generator. The exhaust line of the internal combustion engine contains an exhaust purification system, such as a DeNOx catalytic converter, which is at least temporarily supplied with hydrogen-rich gas through a bypass line. In addition, the exhaust line is in thermal contact with the hydrogen generator in order to recover thermal energy.

Owner:NUCELLSYS GMBH

Variable compression ratio internal combustion engine

The invention is directed to a variable compression ratio internal combustion engine in which the compression ratio of the engine can be varied and multiple types of fuels having different combustion velocities are used. The invention provides a technology for achieving excellent engine performance for respective types of fuels. In the variable compression ratio internal combustion engine in which the compression ratio can be varied and multiple types of fuels having different combustion velocities are injected through multiple fuel injection valves, maps from which a target compression ratio of the internal combustion engine is read out are switched in accordance with the fuel used, thereby suppressing knocking or other disadvantages.

Owner:TOYOTA JIDOSHA KK

Internal combustion engine fuel supply system

InactiveUS7051518B2Reduce nitrogen oxide contentHigh calorific valueInternal combustion piston enginesExhaust apparatusThermal energyHydrogen

A system to supply hydrogen-rich fuel to an internal combustion engine, whereby a hydrogen-rich gas is produced from a liquid raw fuel by a hydrogen generator. The exhaust line of the internal combustion engine contains an exhaust purification system, such as a DeNOx catalytic converter, which is at least temporarily supplied with hydrogen-rich gas through a bypass line. In addition, the exhaust line is in thermal contact with the hydrogen generator in order to recover thermal energy.

Owner:NUCELLSYS GMBH

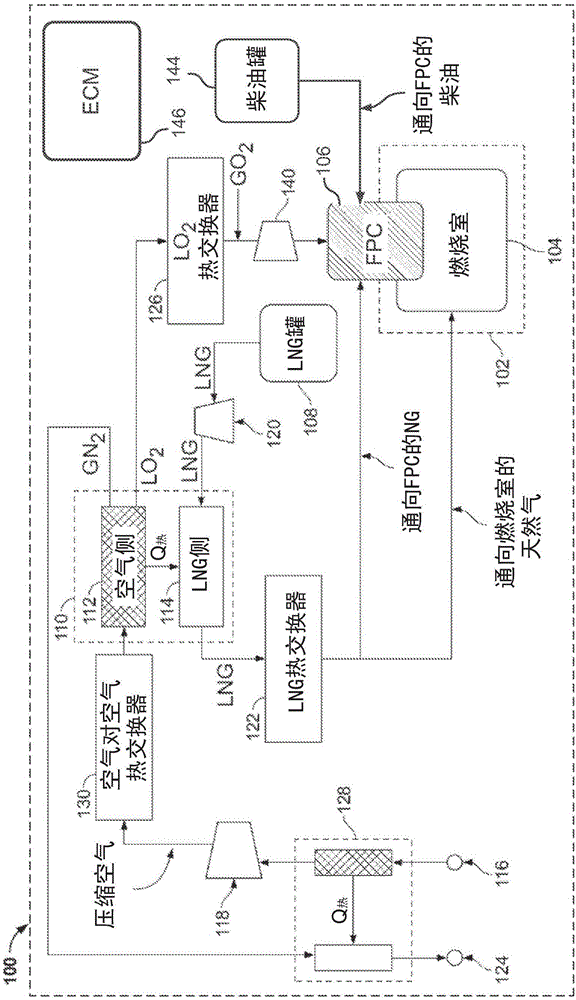

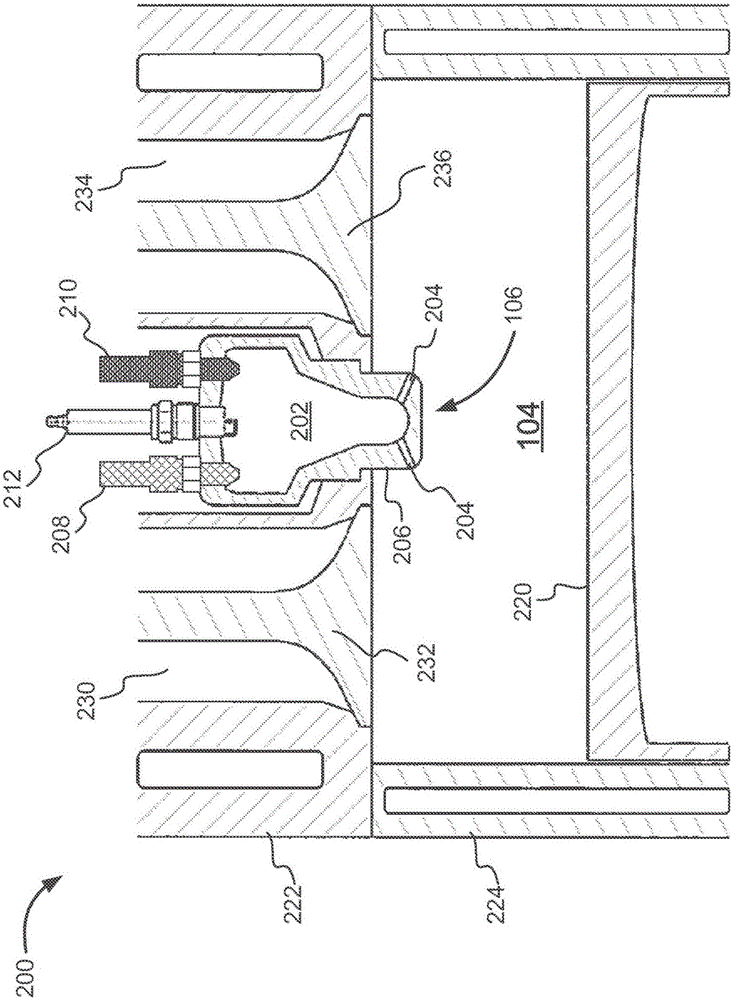

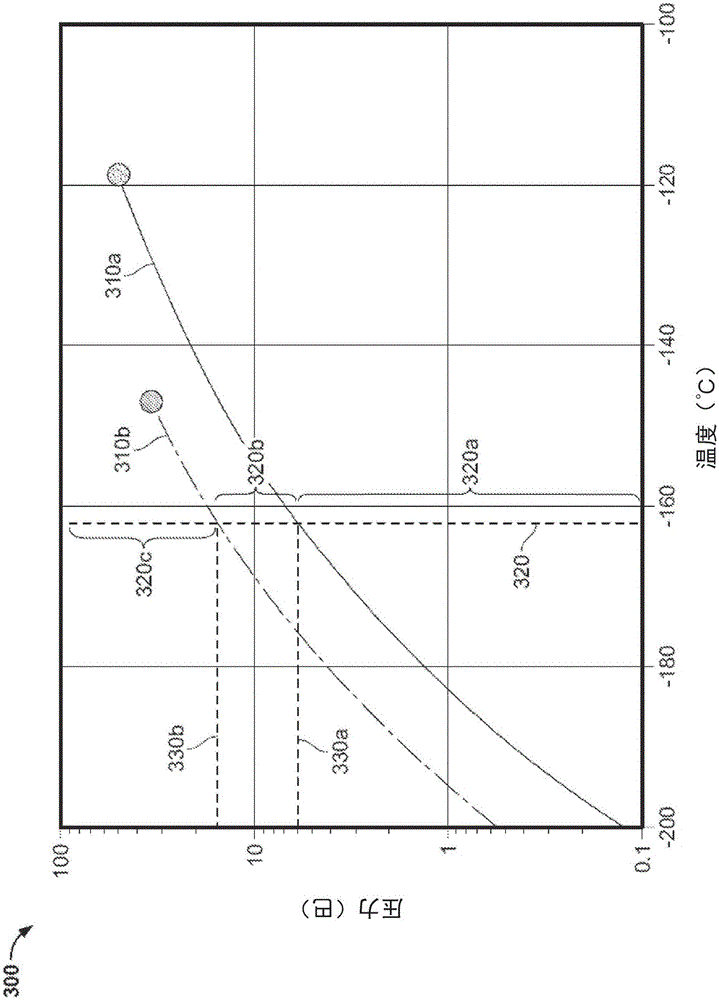

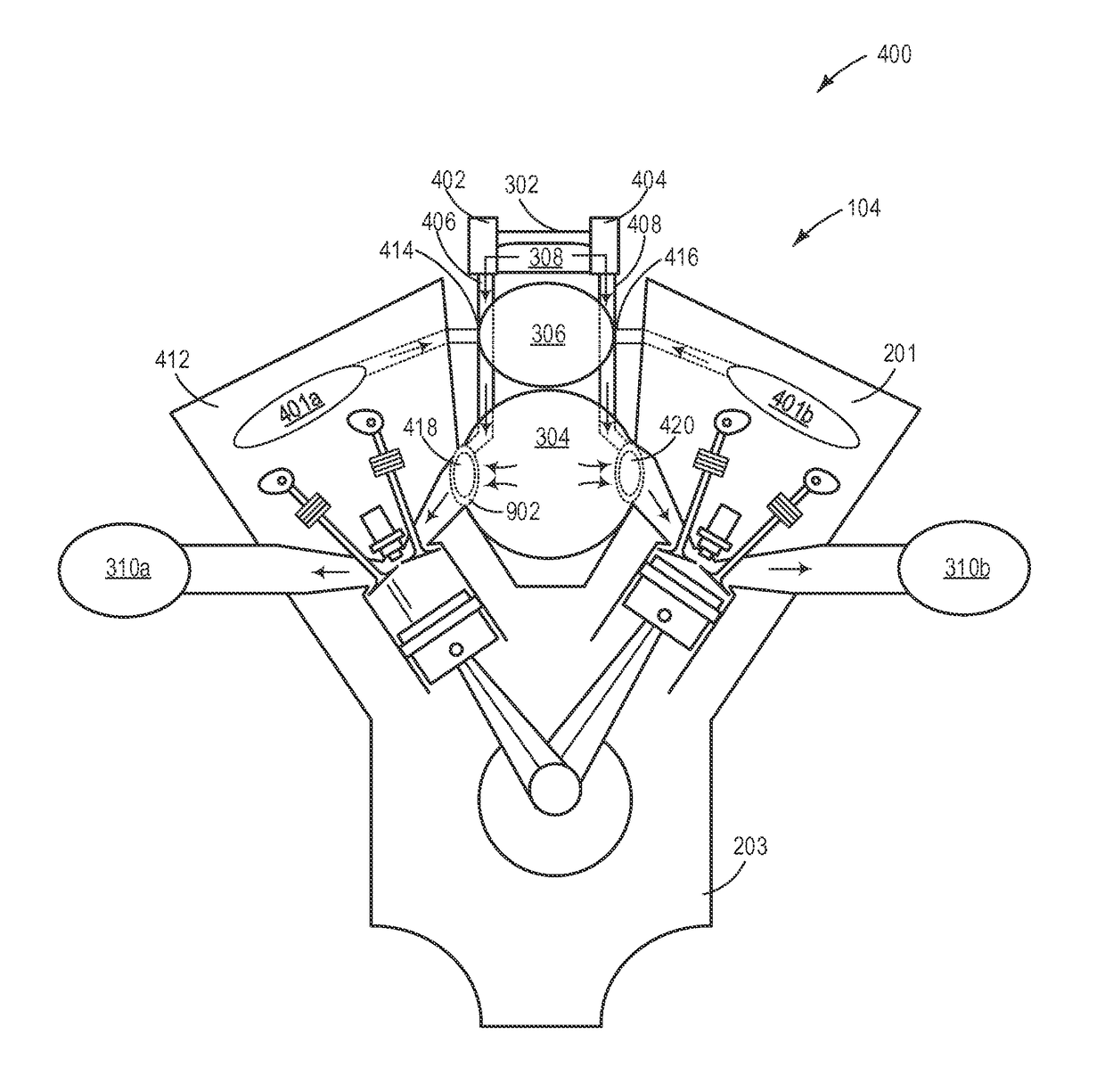

Use of prechambers with dual fuel source engines

InactiveCN106460741AElectrical controlNon-fuel substance addition to fuelCombustion chamberLiquid fuel

A system has an engine. The engine has a combustion chamber, a pre-combustion chamber apart from the combustion chamber, and an opening spanning between the combustion chamber and the pre-combustion chamber. The engine also has a first fuel supply system adapted to supply liquid fuel to the pre-combustion chamber and a second fuel supply system adapted to supply a second, different fuel to the combustion chamber. In certain instances, an oxygen supply system supplies oxygen into the prechamber.

Owner:WOODWARD GOVERNOR CO

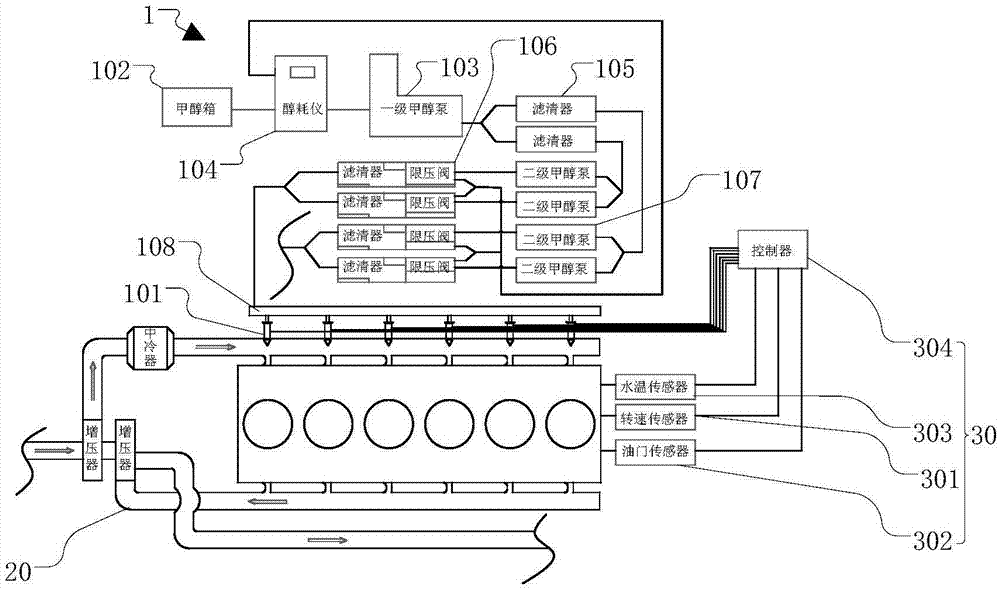

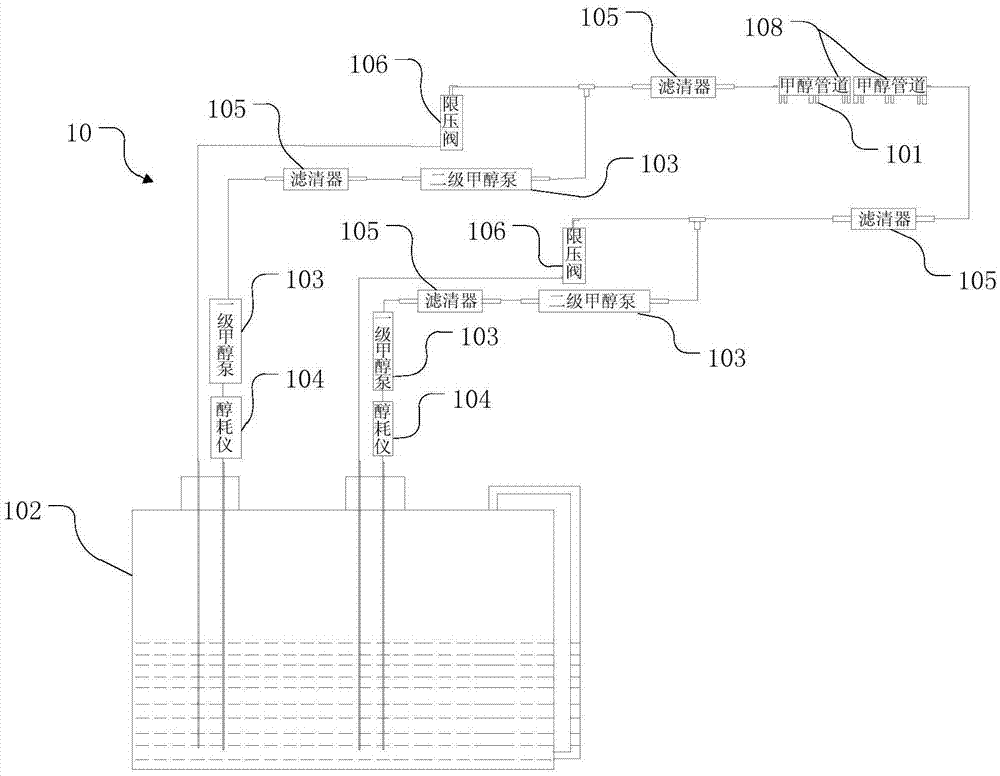

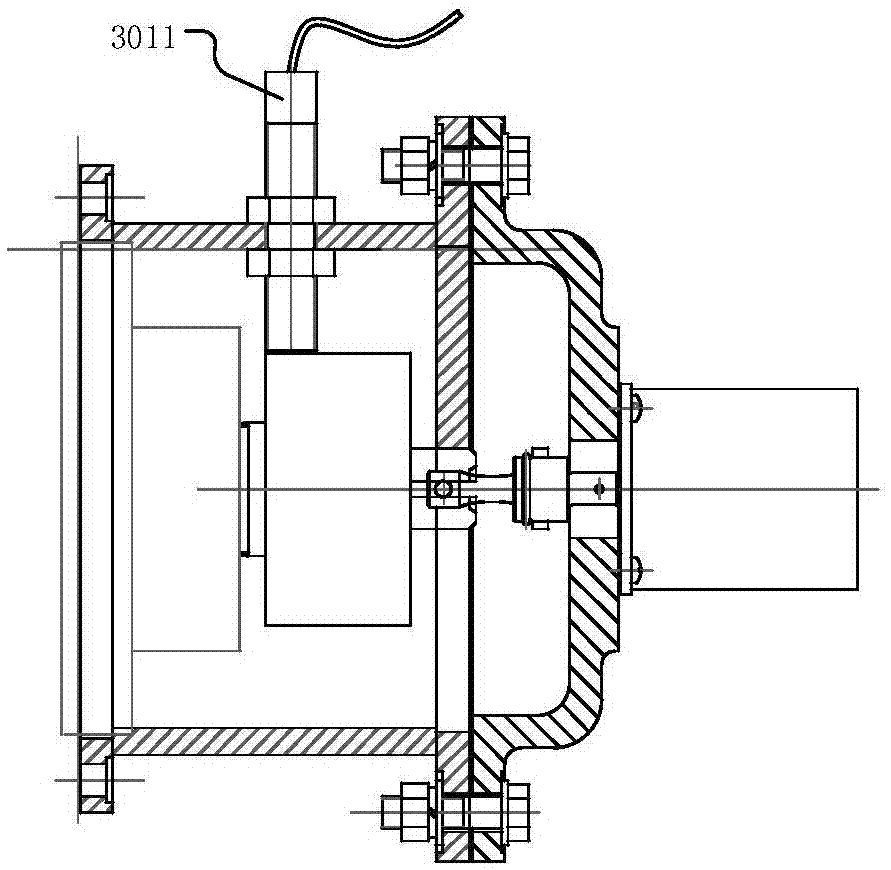

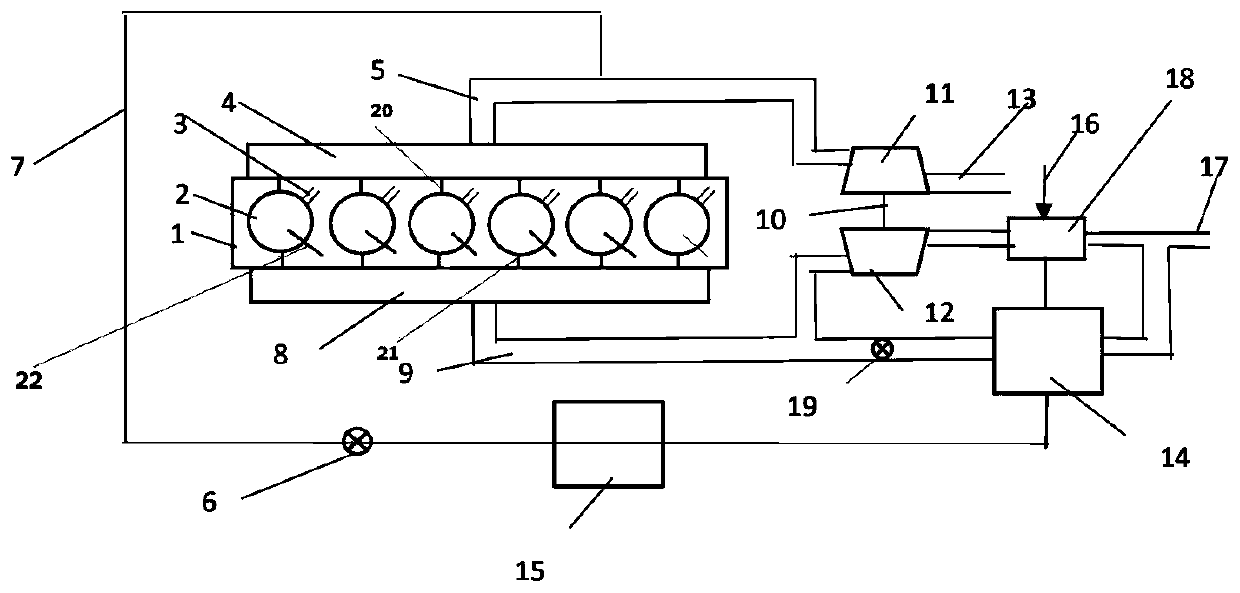

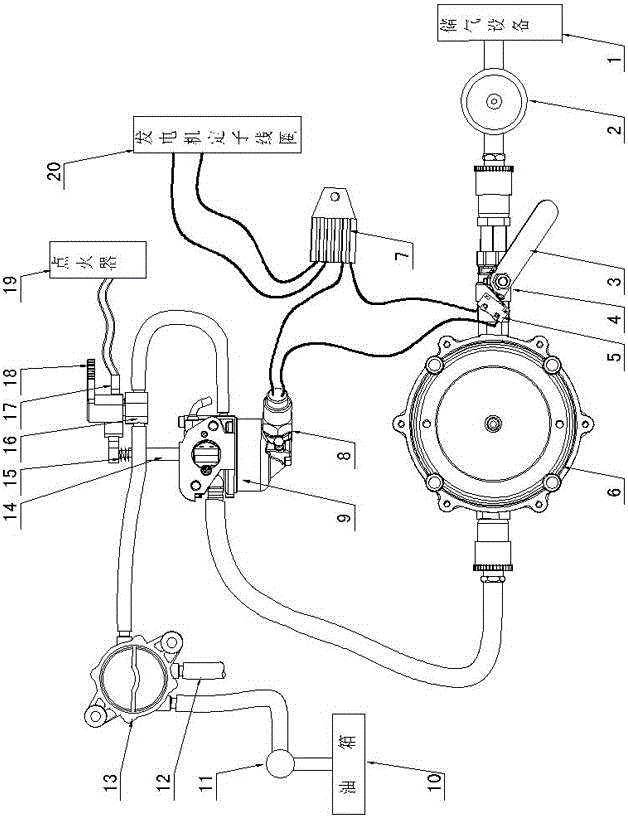

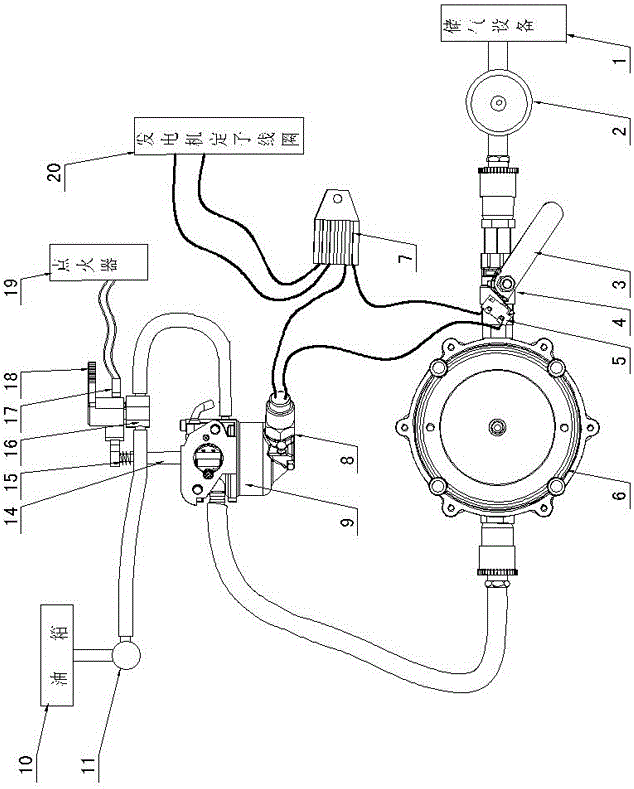

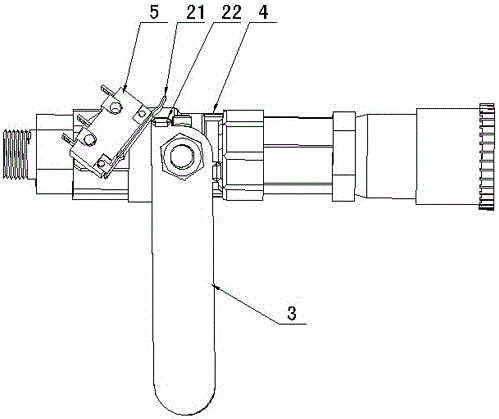

Methanol-diesel oil dual-fuel engine and rail locomotive

InactiveCN105443241AReduce use costElectrical controlInternal combustion piston enginesStart timeCombustion chamber

The invention provides a methanol-diesel oil dual-fuel engine and a rail locomotive. The methanol-diesel oil dual-fuel engine comprises: a diesel oil engine, a methanol injection system and an electronic control system; the methanol injection system comprises: a methanol tank connected through a primary methanol pump and a methanol nozzle mounted at a combustion chamber; a controller of the electronic control system controls injection starting time and injection mass of methanol according to acquired rotating speed of the engine, throttle opening and water temperature. The rail locomotive is provided with such a methanol-diesel oil dual-fuel engine. According to the methanol-diesel oil dual-fuel engine and the rail locomotive provided by the present invention, the injection starting time and injection mass of the methanol are controlled according to the rotating speed of the engine, the throttle opening and the water temperature, and therefore, the methanol and the diesel oil do not need to be premixed by adding a co-solvent and the cost of the fuels is reduced.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

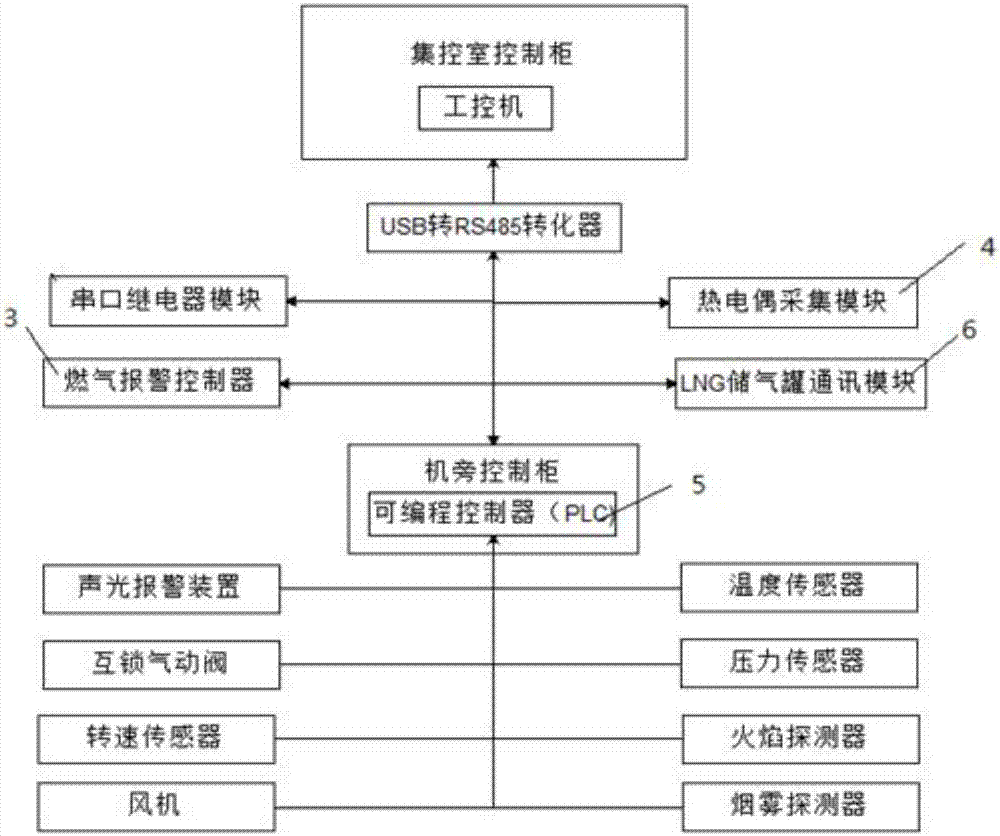

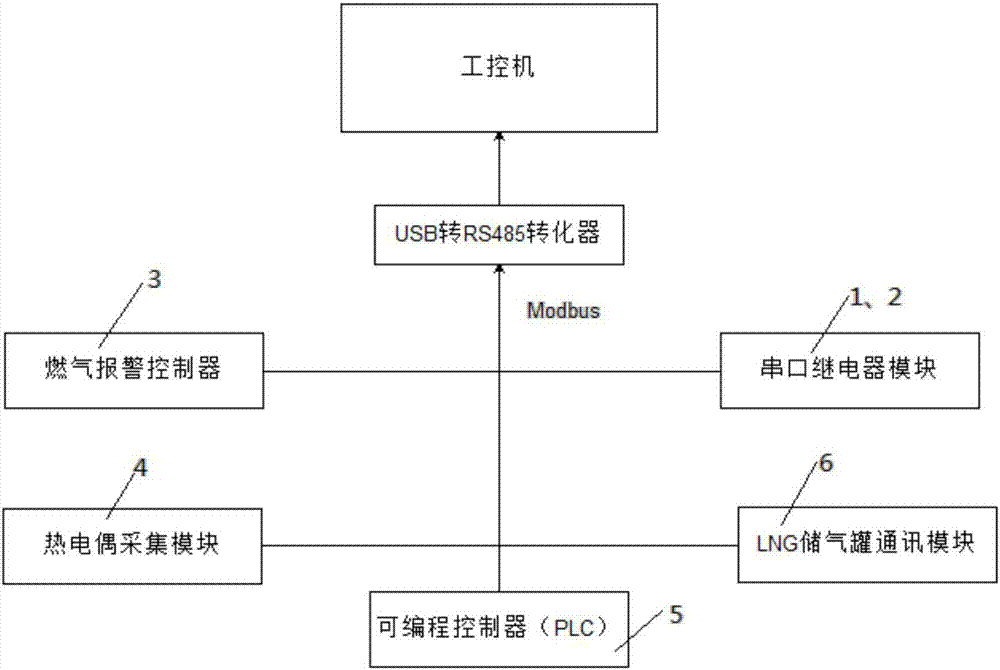

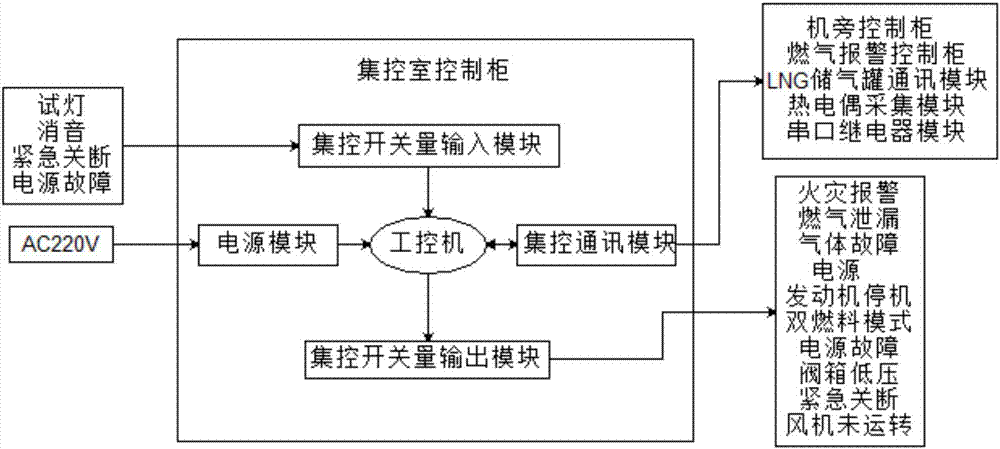

Marine LNG/diesel oil dual-fuel engine safety monitoring system

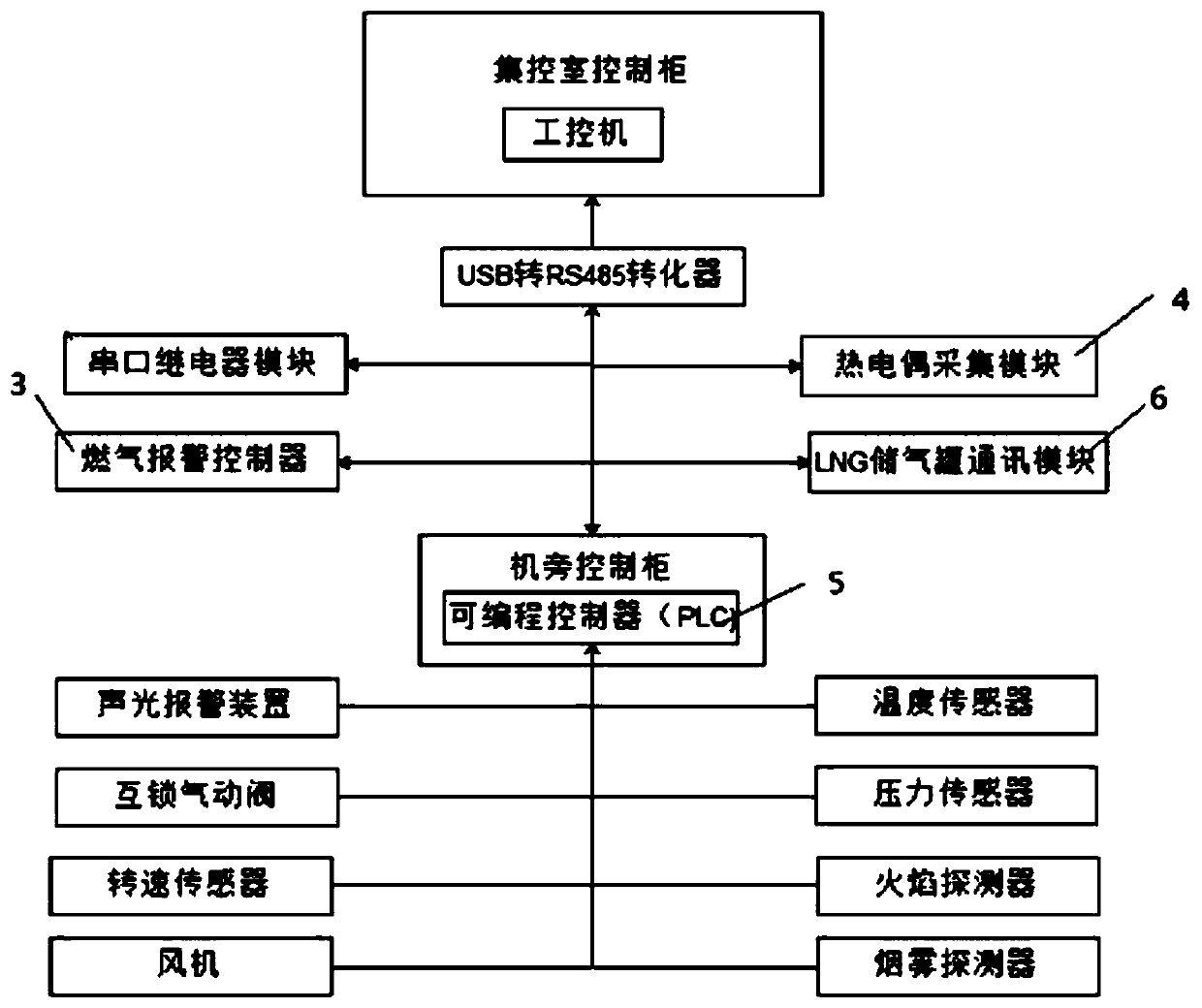

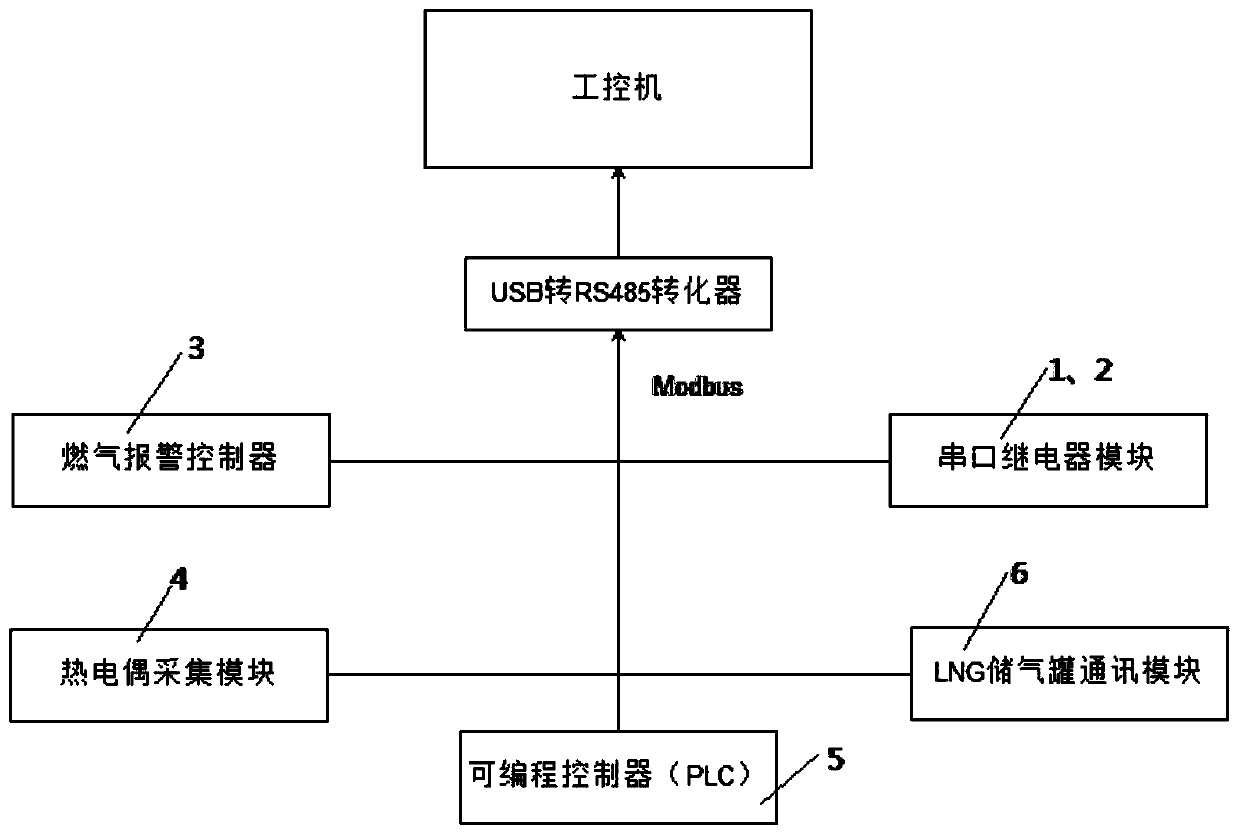

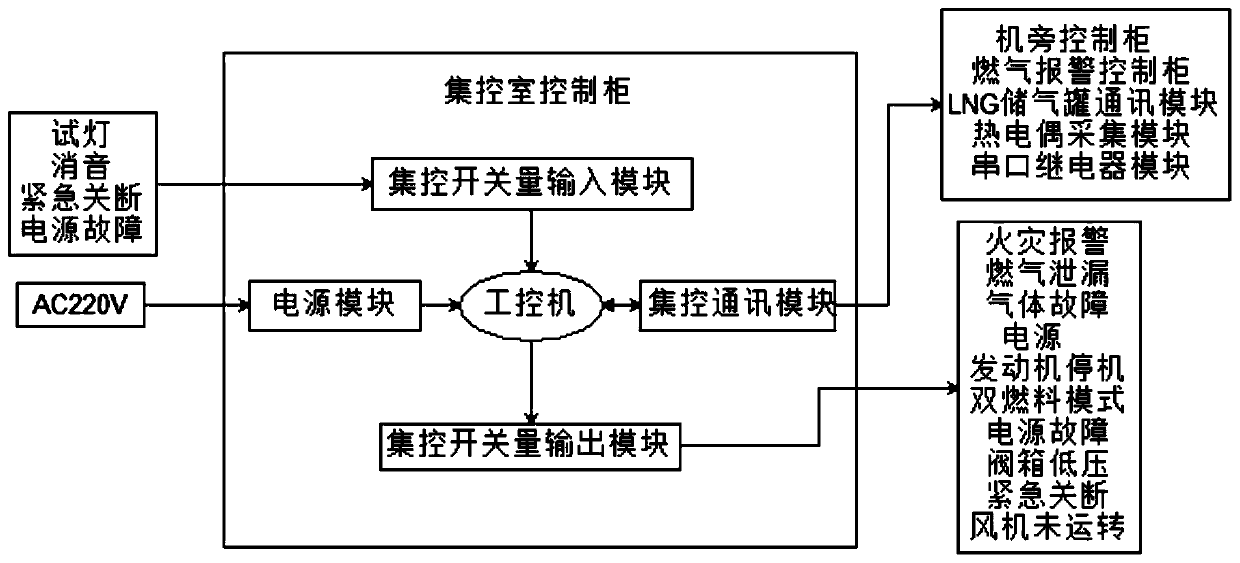

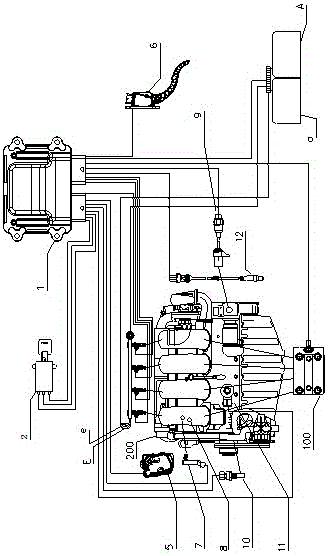

InactiveCN107035521AEasy to analyzeEasy to handleInternal combustion piston enginesEngine controllersUSBSafety monitoring

The invention discloses a marine LNG / diesel oil dual-fuel engine safety monitoring system. A central control room control cabinet serves as a core of an overall system, an industrial personal computer in the central control room control cabinet is connected with a programmable logic controller, a fuel gas alarming controller, an LNG air storage tank communication module, a thermocouple collecting module and a serial port relay module which are arranged in an on-site control cabinet through a USB-to-RS485 converter. The programmable logic controller in the on-site control cabinet is connected with a rotating speed sensor, a temperature sensor, a pressure sensor, a flame detector and an interlocking gas valve. The fuel gas alarming controller module is connected with a fuel gas detector. The LNG air storage tank communication module is connected with a gas tank pressure and liquid level sensor. The thermocouple collecting module is connected with an air cylinder exhaust temperature sensor. A real-time and accurate safety monitoring data report can be provided, analysis and treatment on the LNG / diesel oil dual-fuel engine system in the later period are facilitated, and the safety monitoring system can be conveniently used for engines in different types and different monitoring schemes.

Owner:WUHAN UNIV OF TECH

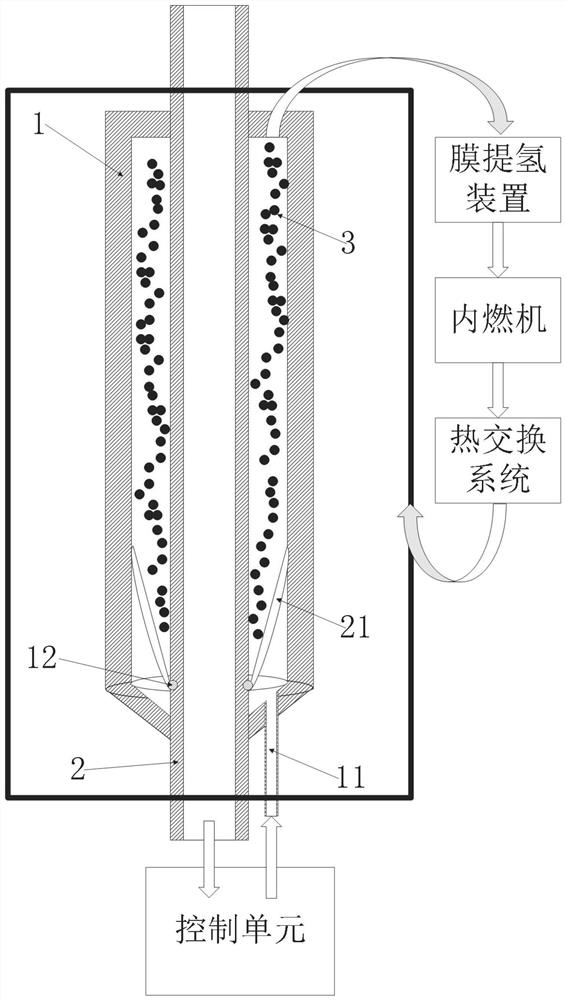

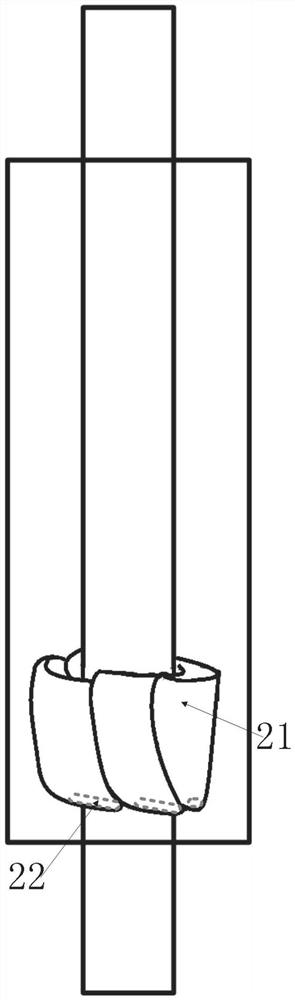

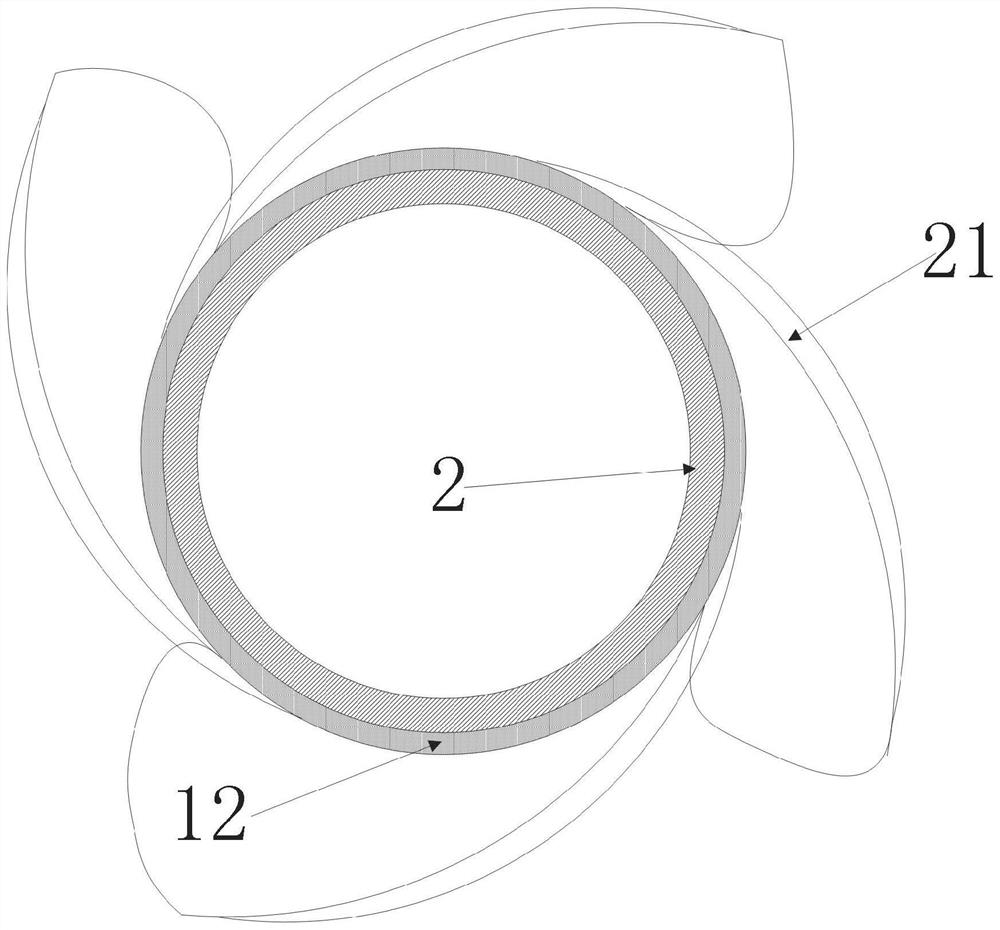

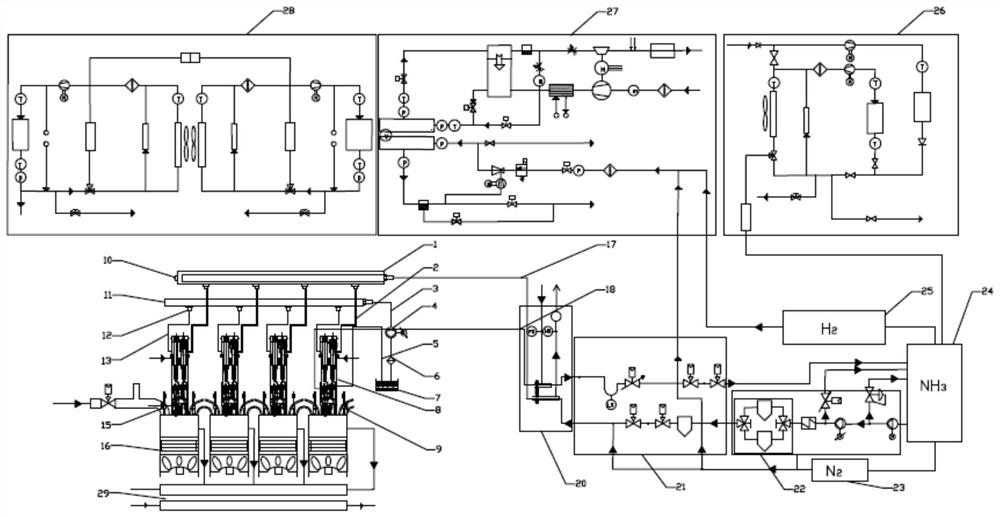

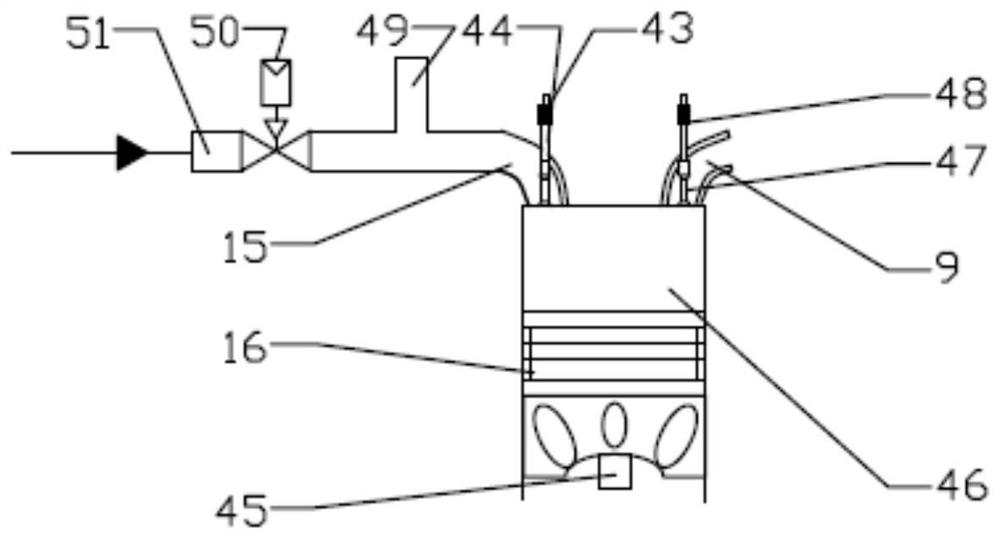

Methanol engine system adopting methanol to produce hydrogen serving as ignition agent and operation method of methanol engine system

ActiveCN110273790AAccurate supplyComplete replacementInternal combustion piston enginesNon-fuel substance addition to fuelGas supplyHydrogen production

The invention belongs to the technical field of engines, and particularly relates to a methanol engine system adopting methanol to produce hydrogen serving as an ignition agent and an operation method of the methanol engine system. The methanol engine system adopting a two-level heating methanol hydrogen production manner comprises a methanol engine, a gas supply system and an exhaust system, wherein the gas supply system comprises a methanol heater and a methanol hydrogen production device. The invention further discloses the operation method of the methanol engine system. According to the methanol engine system and the operation method of the methanol engine system, methanol-based fuel is adopted for the reaction to generate the hydrogen serving as the ignition agent, ignition agent preparing and stable, continuous and accurate supply to the engine are achieved, and completely replacing the diesel fuel with the methanol-based fuel is achieved under the situation of no need to change the structure of the engine.

Owner:SHENZHEN REVELATION TECH CO LTD

Multifuel supply system

A system for connecting a supply of alternative oil to a diesel engine which uses heated engine coolant and electric heat to prevent engine line restriction due to gelled alternative oil.

Owner:PLANT OIL POWERED DIESEL FUEL SYST

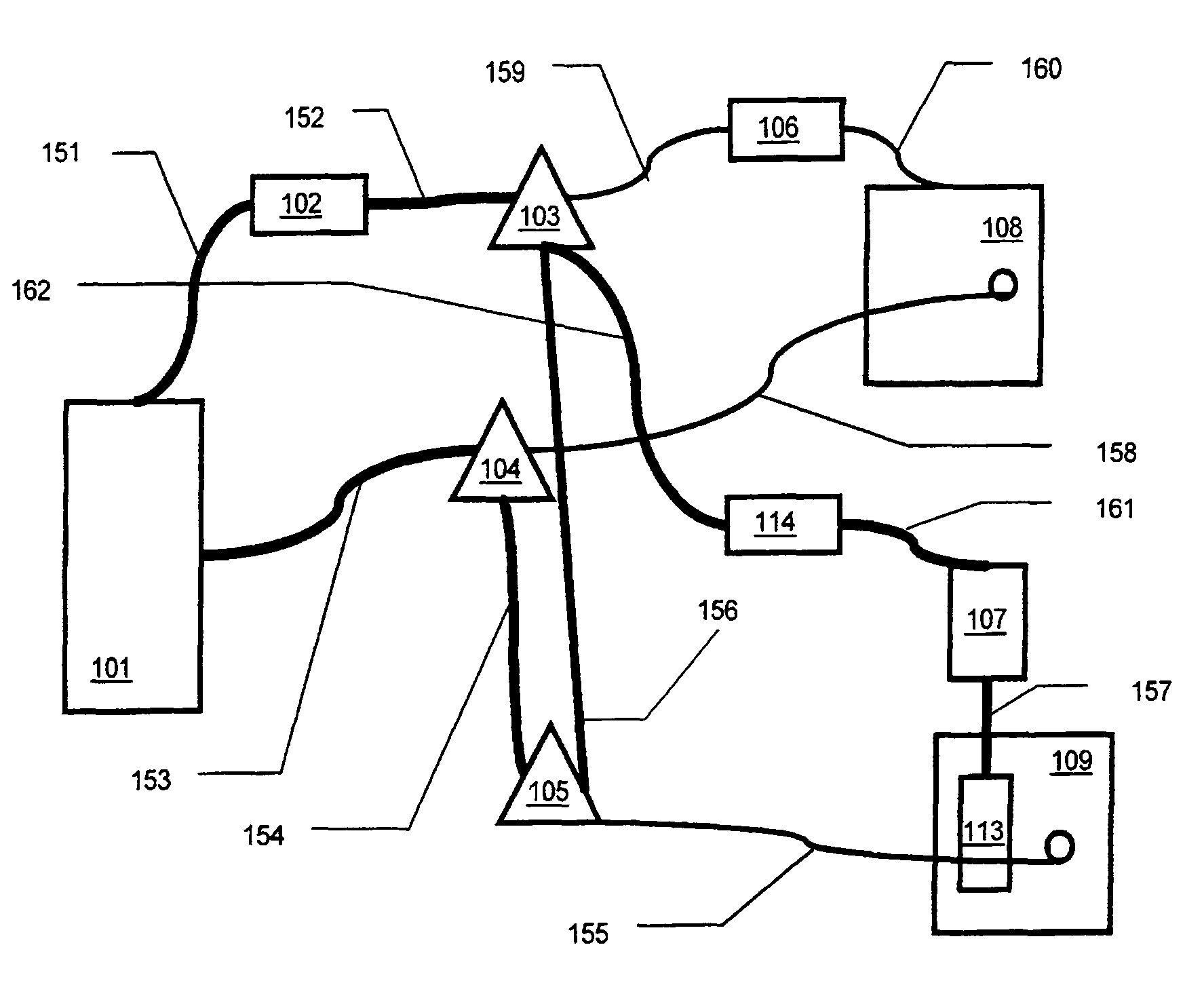

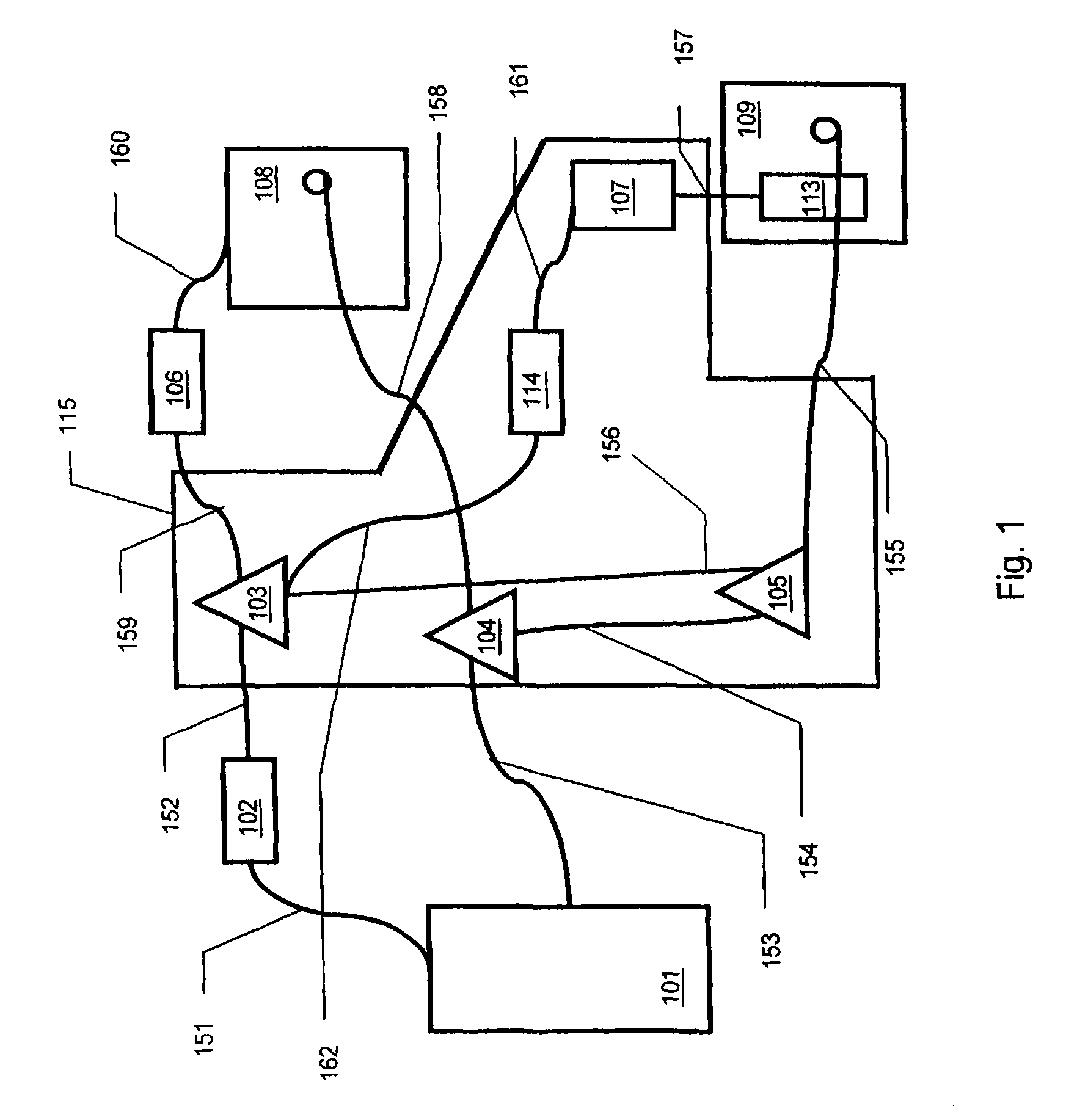

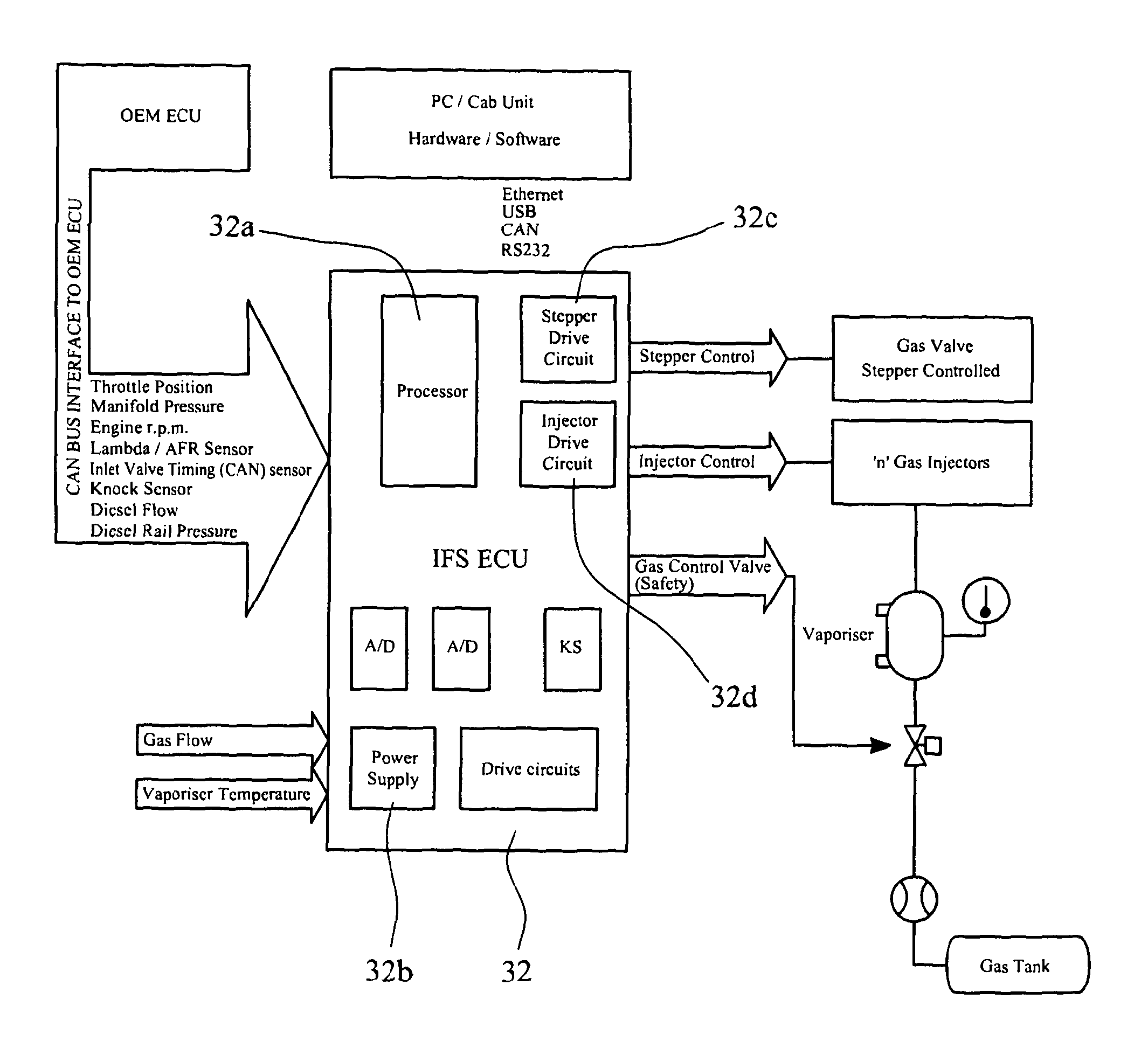

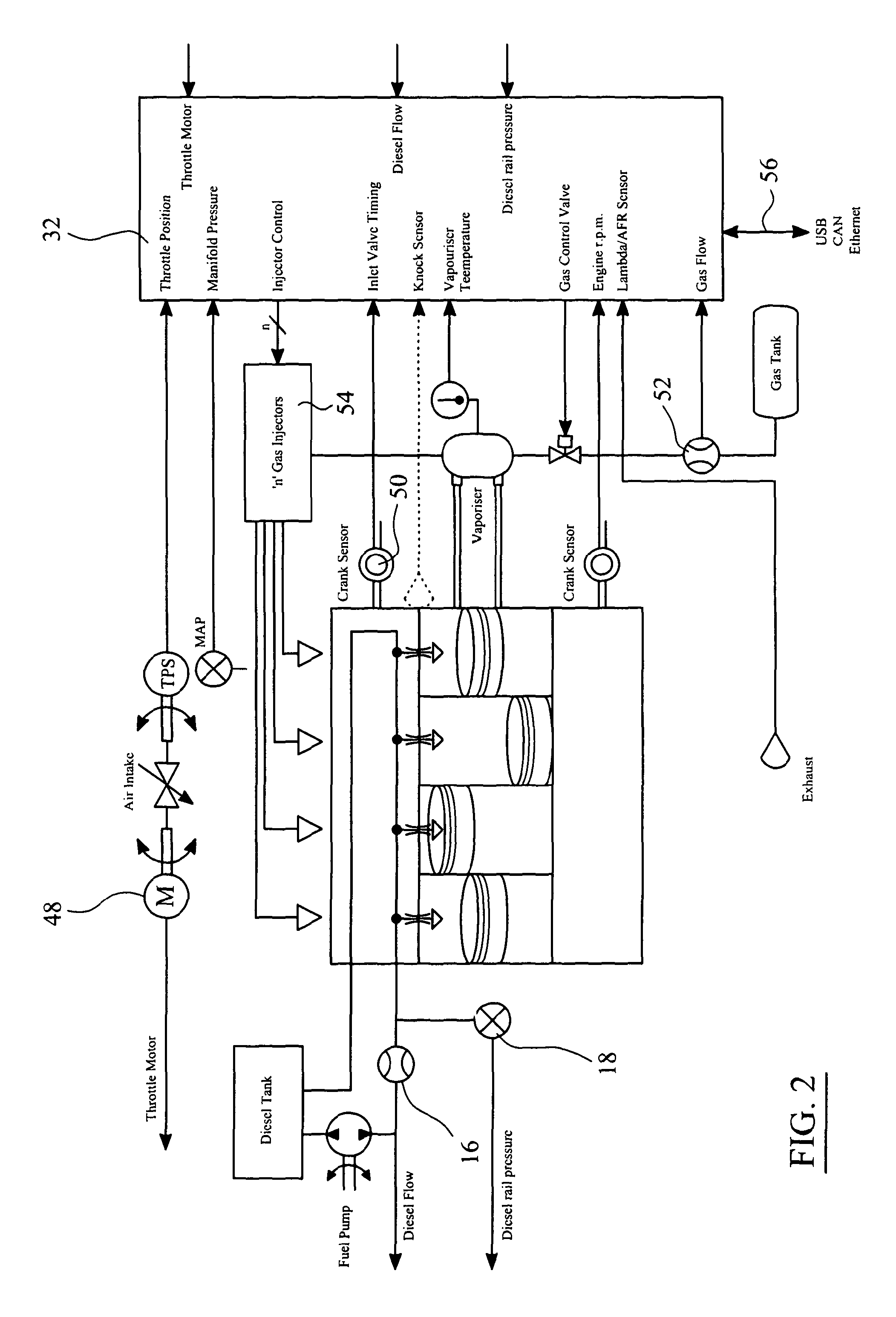

Apparatus and method for controlling a multi-fuel engine

ActiveUS9145838B2Improve economyReduce supplyElectrical controlInternal combustion piston enginesElectronic controllerCombustion

A dual-fuel engine has a primary fuel supply and a secondary fuel supply, the primary and secondary fuels being arranged in use to mix with each other and with air for combustion in one or more cylinders of the engine. The supply of both the primary and secondary fuels is arranged to be actively managed in accordance with a desired engine performance characteristic by an electronic controller. In one arrangement the supply of a primary fuel is arranged to be actively reduced when a secondary fuel is supplied to the engine.

Owner:INTELLIGENT DIESEL SYST

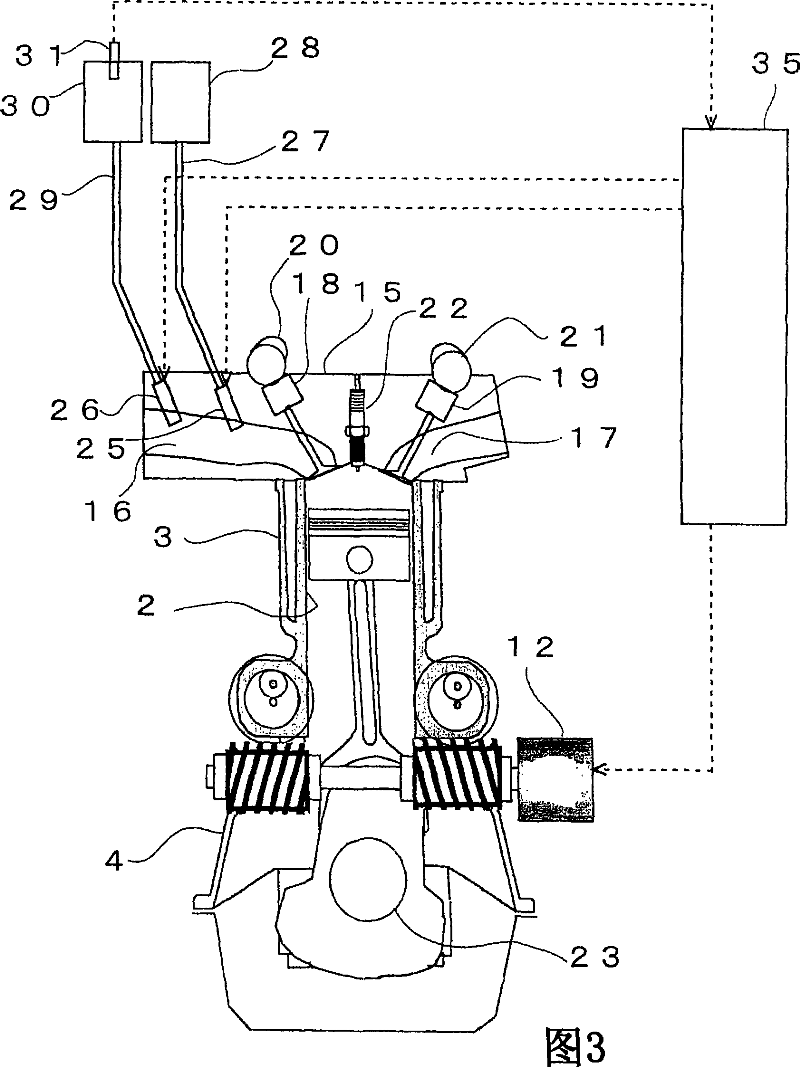

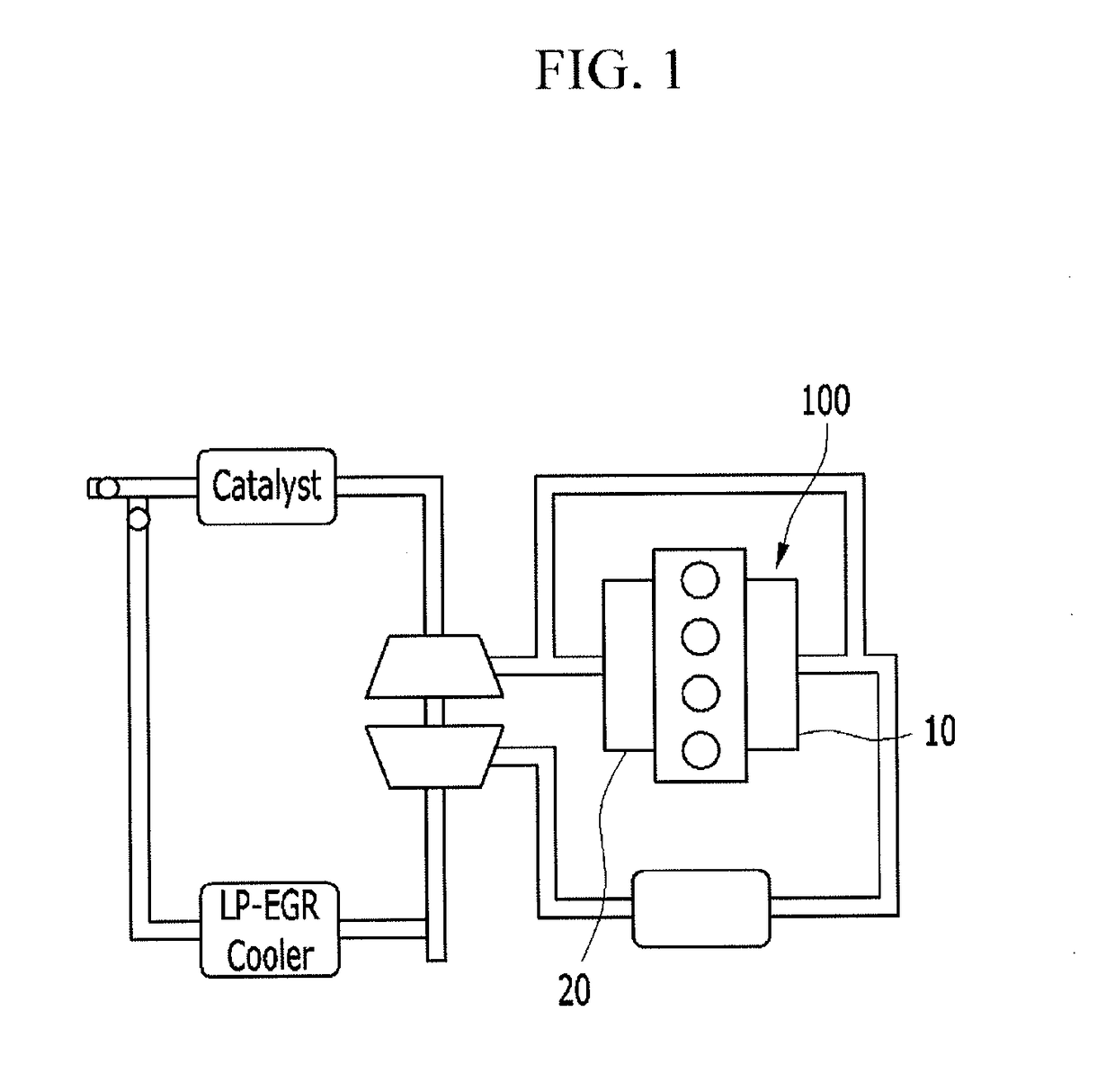

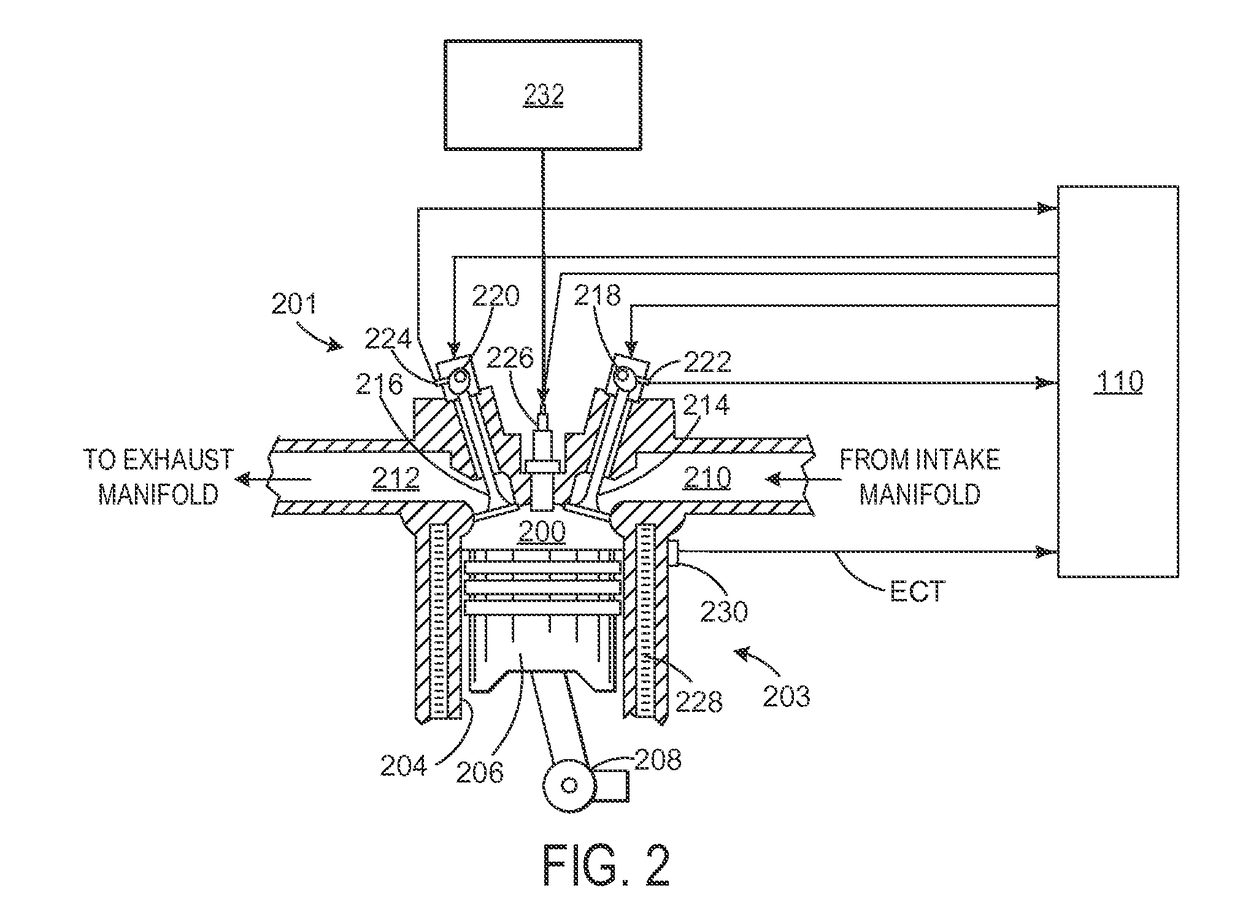

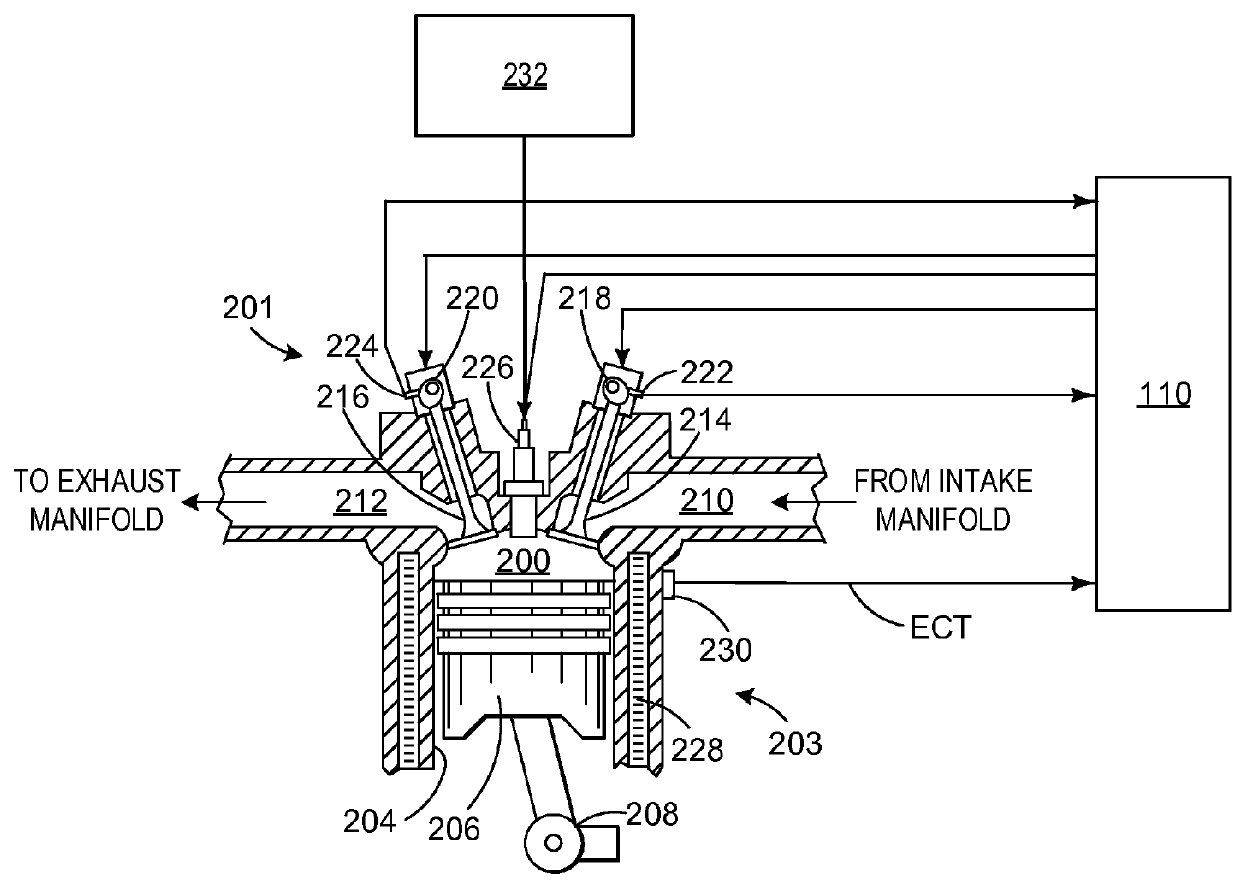

Gasoline-diesel complex combustion engine

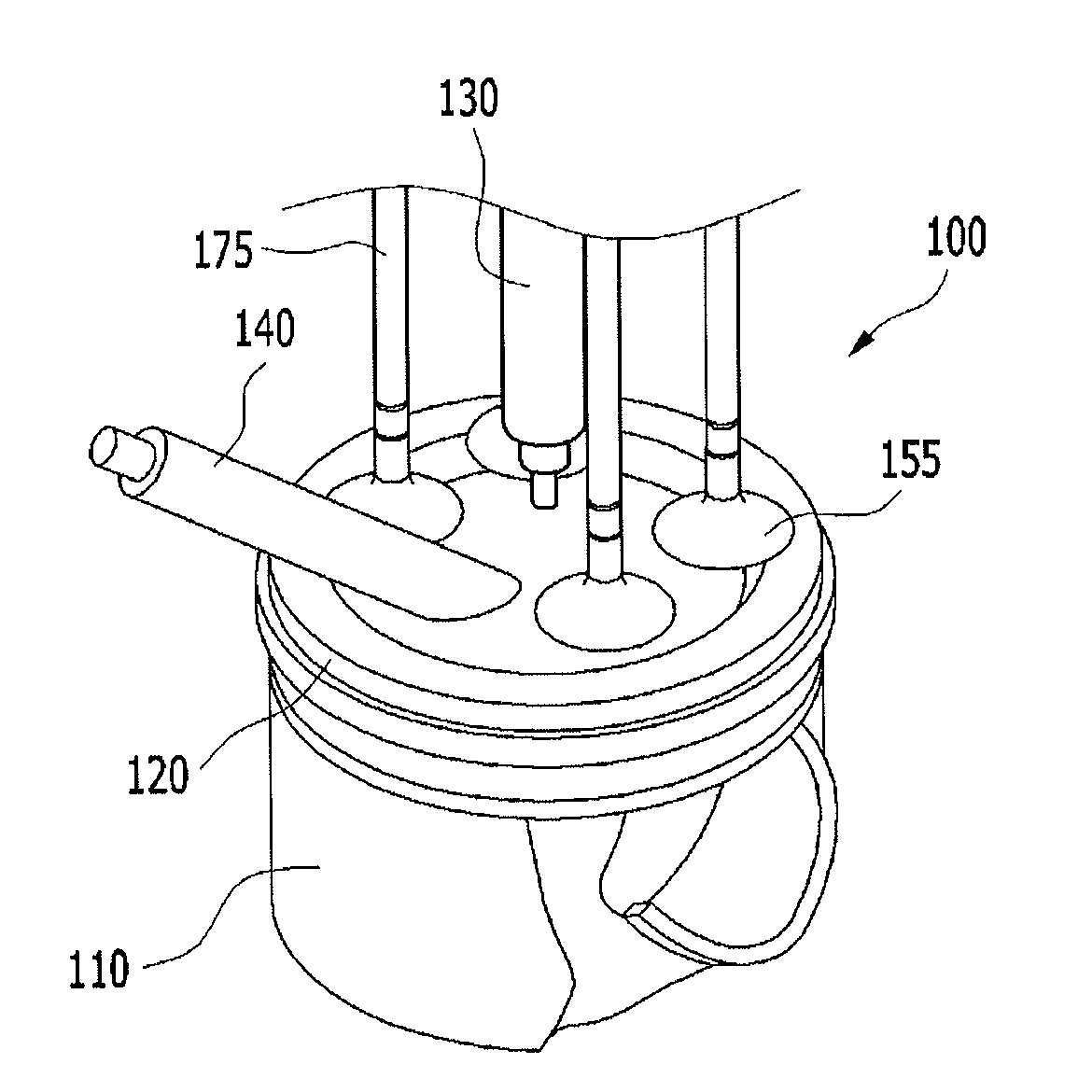

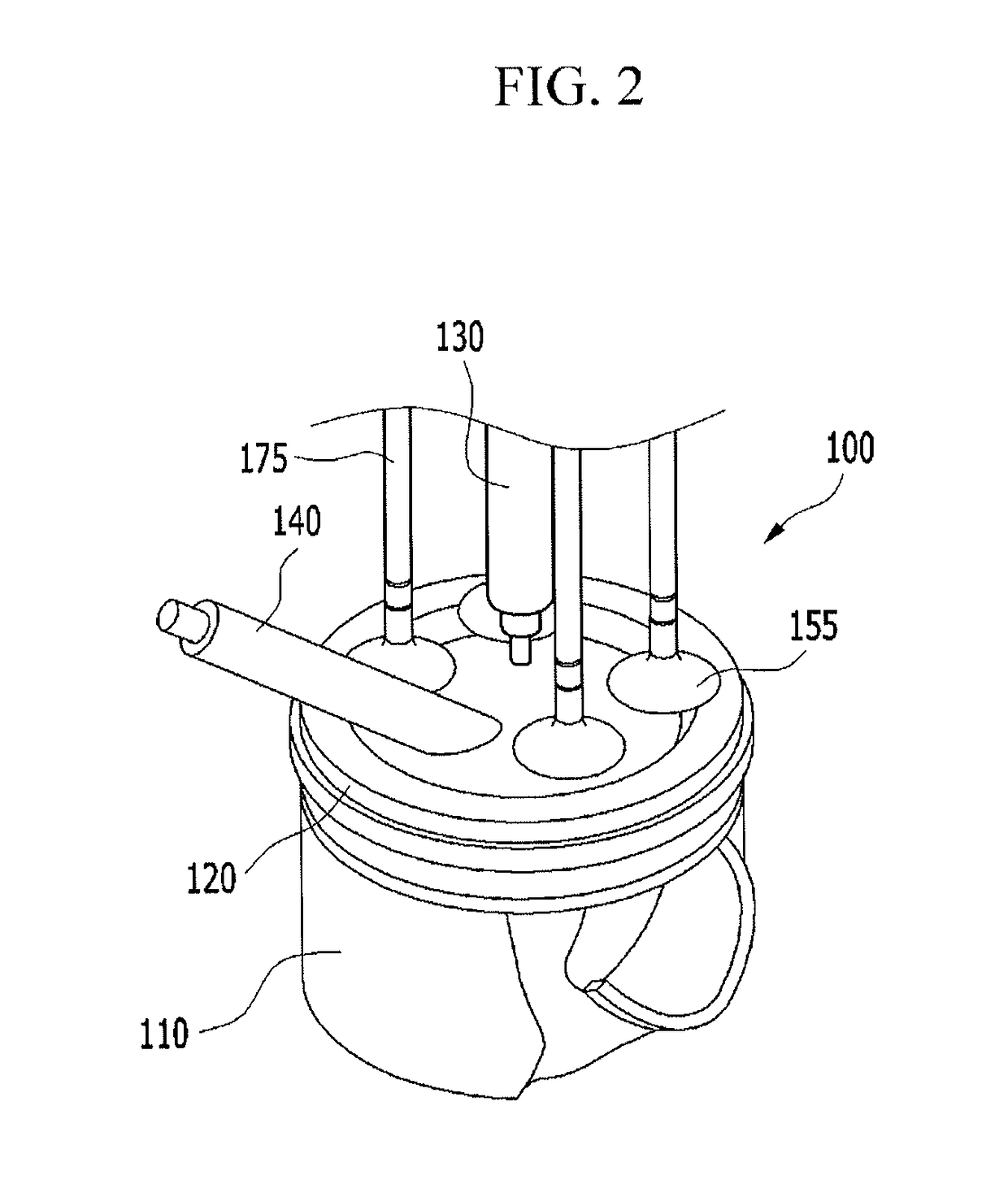

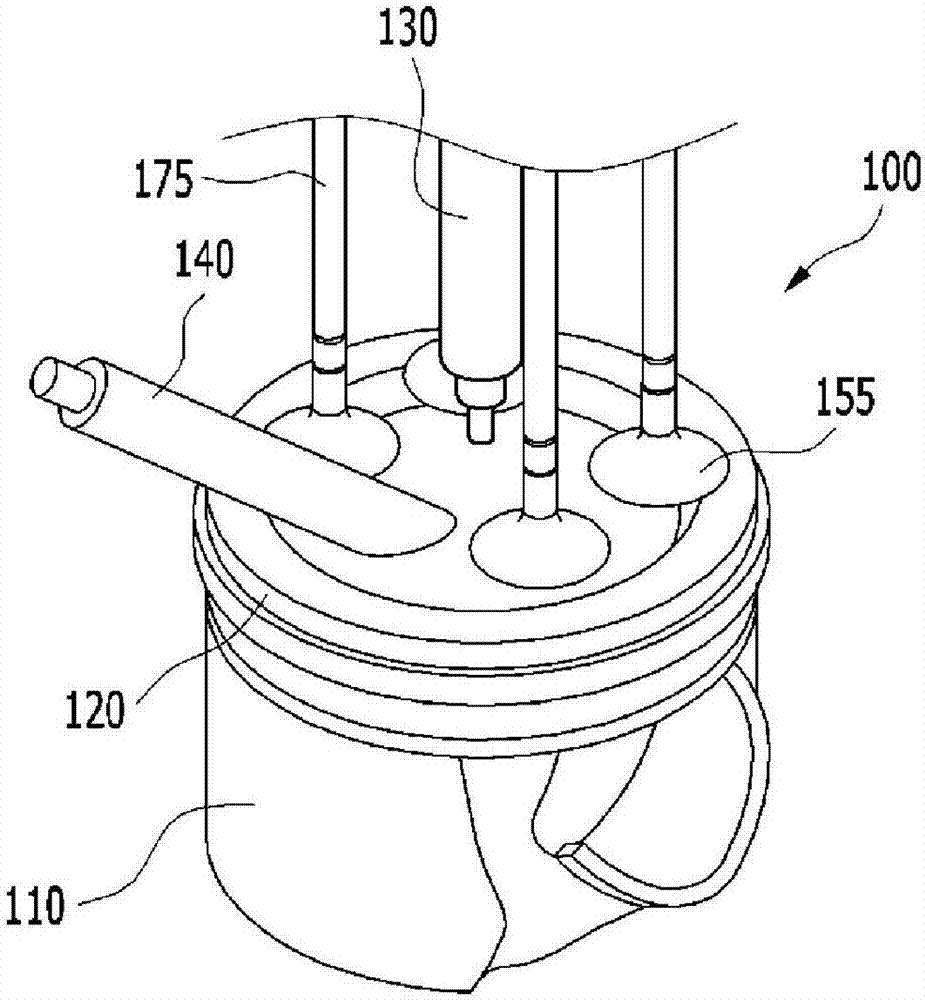

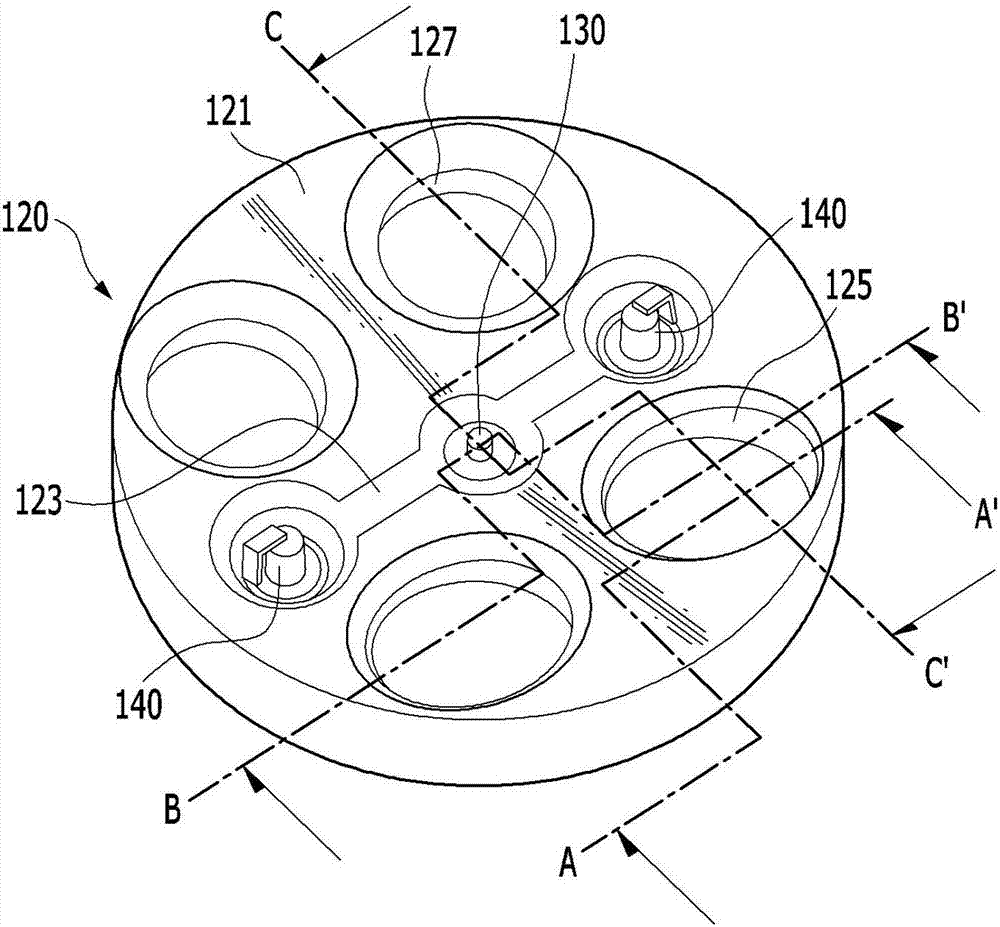

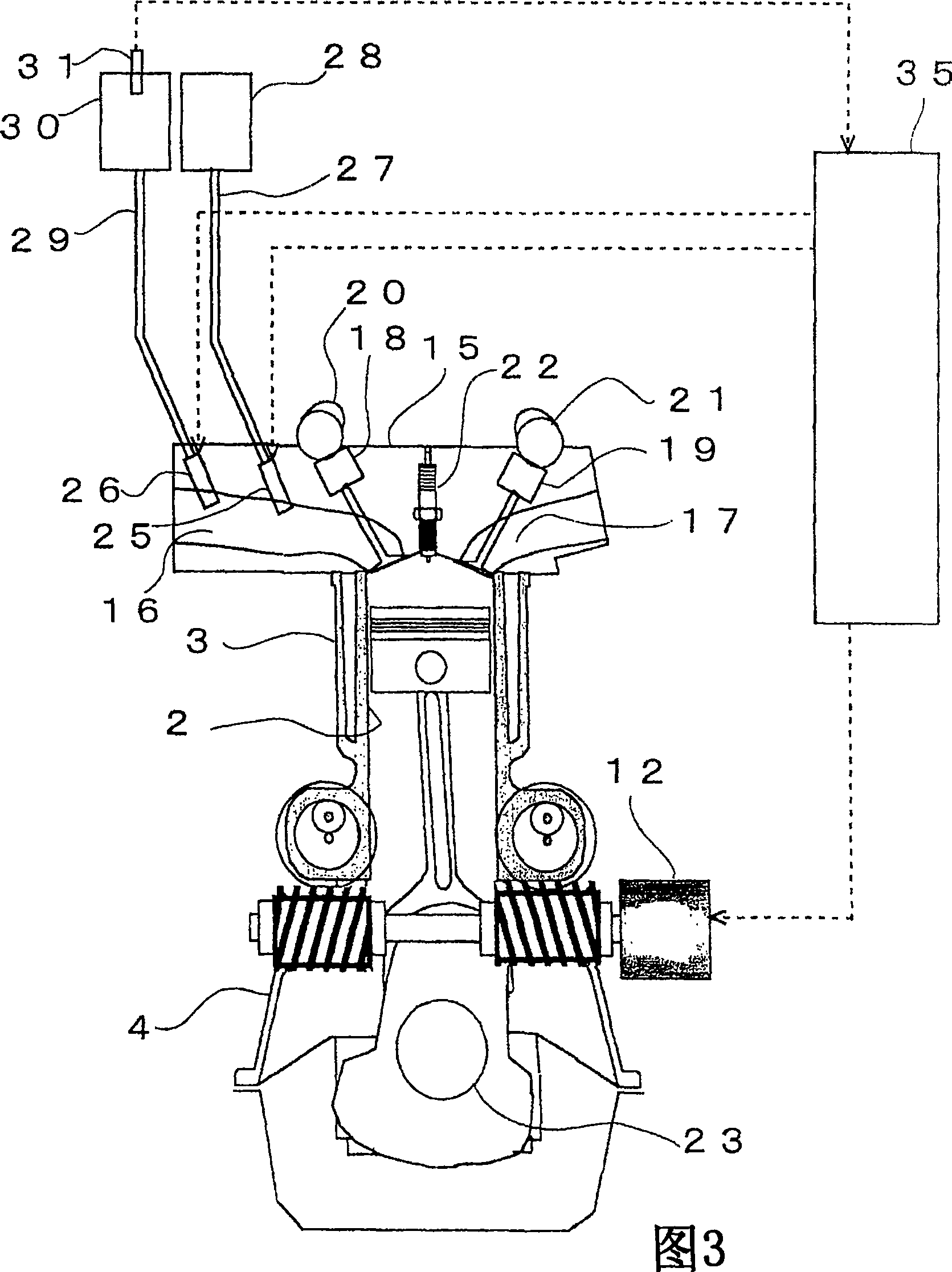

InactiveUS20170167456A1Avoid knockingEfficient chargingElectrical controlInternal combustion piston enginesCombustion chamberGasoline fuel

A gasoline-diesel complex combustion engine may include a cylinder including a cylinder body in which a combustion chamber is formed to generate a driving power by combusting a gasoline fuel and a diesel fuel and a cylinder head formed to cover an upper portion of the cylinder body, a pair of intake ports formed in the cylinder head, a pair of exhaust ports formed in the cylinder head, a diesel injector disposed in a center of the cylinder head, a pair of spark plugs disposed on opposite sides of the diesel injector, a first intake pipe and a second intake pipe mounted in the intake ports, an exhaust pipe mounted in the exhaust ports, a pair of intake valves disposed in the first and second intake pipes, and a gasoline injector disposed in the first and second intake pipes to inject the gasoline fuel into the combustion chamber.

Owner:HYUNDAI MOTOR CO LTD

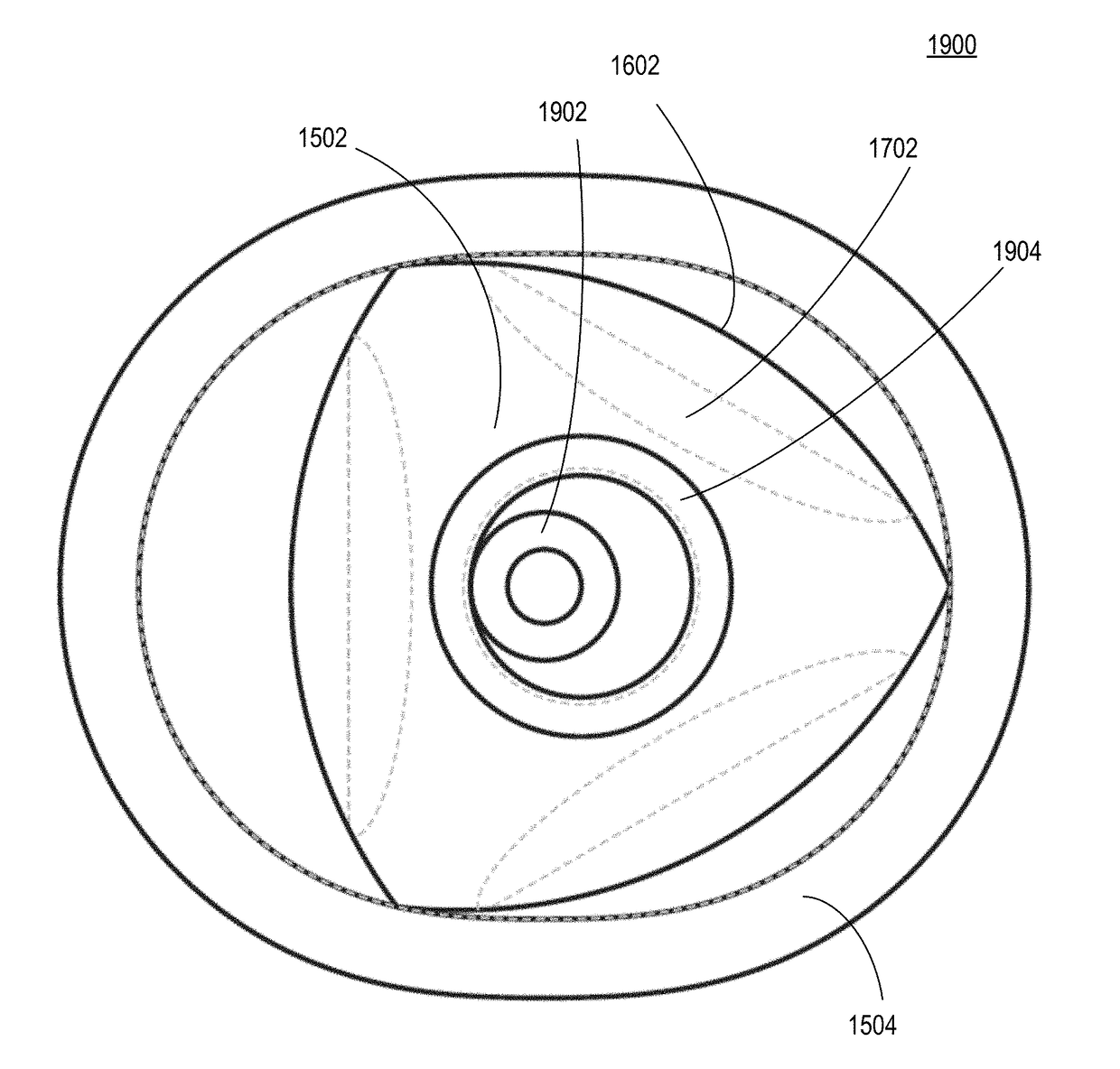

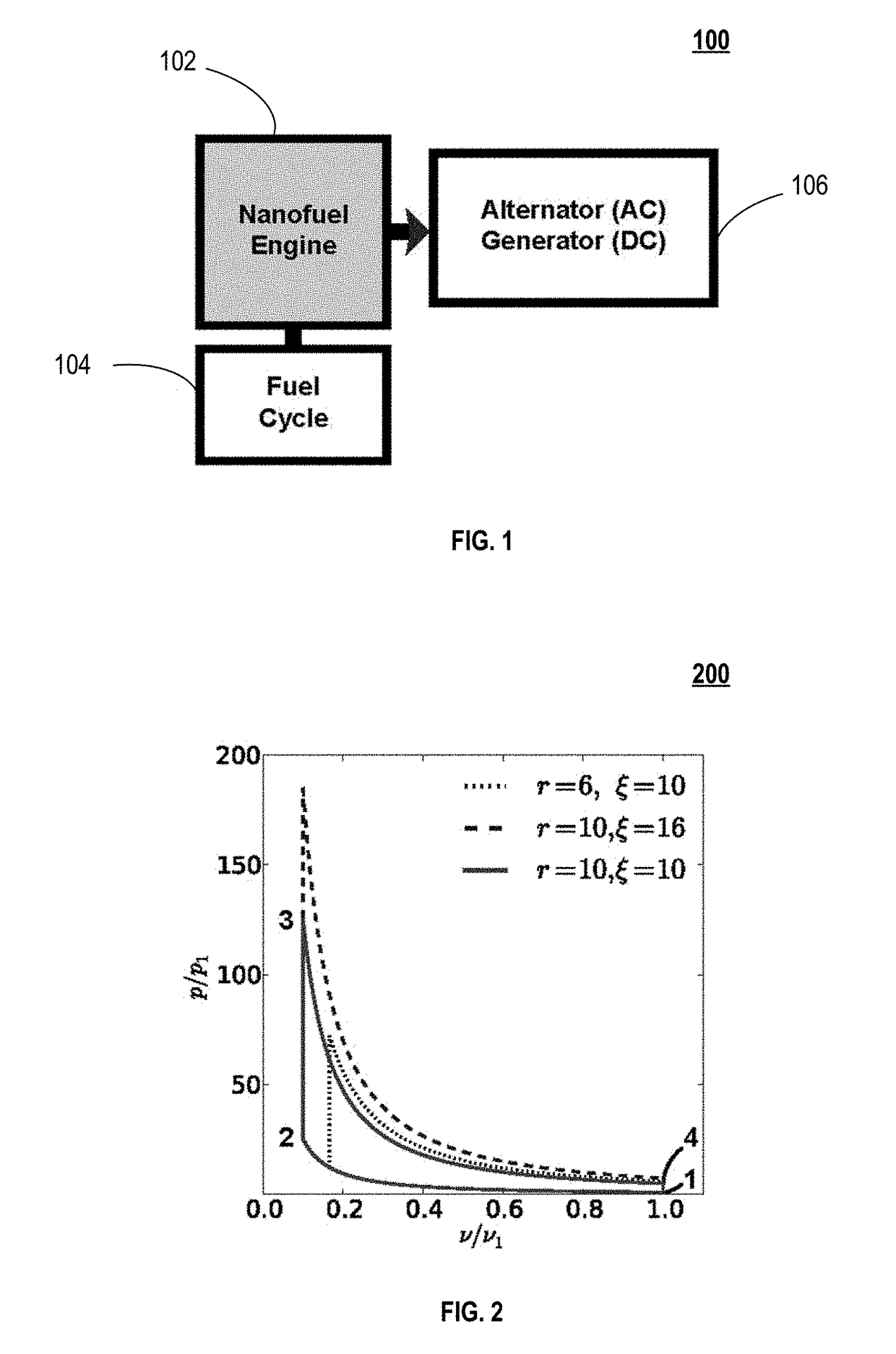

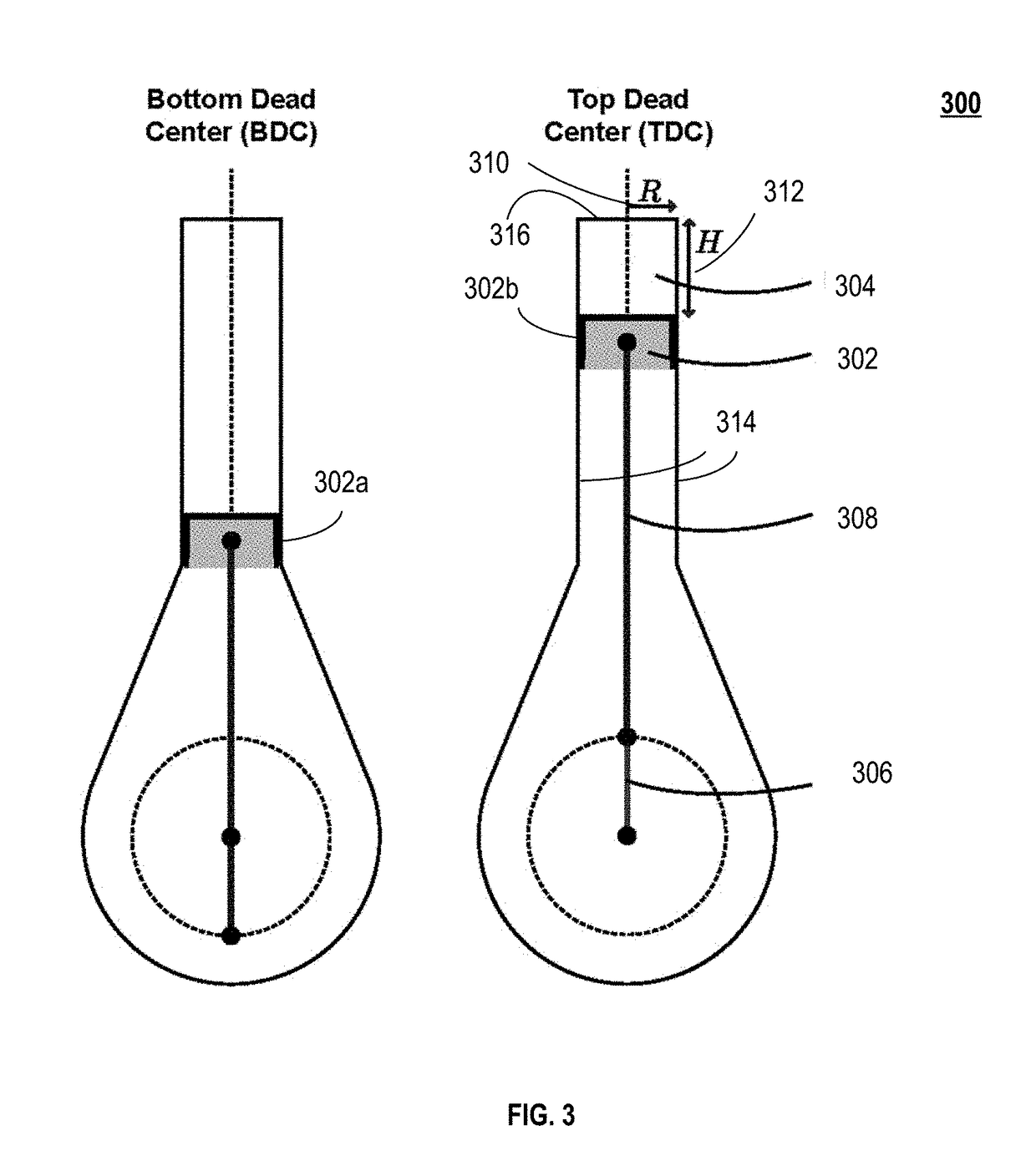

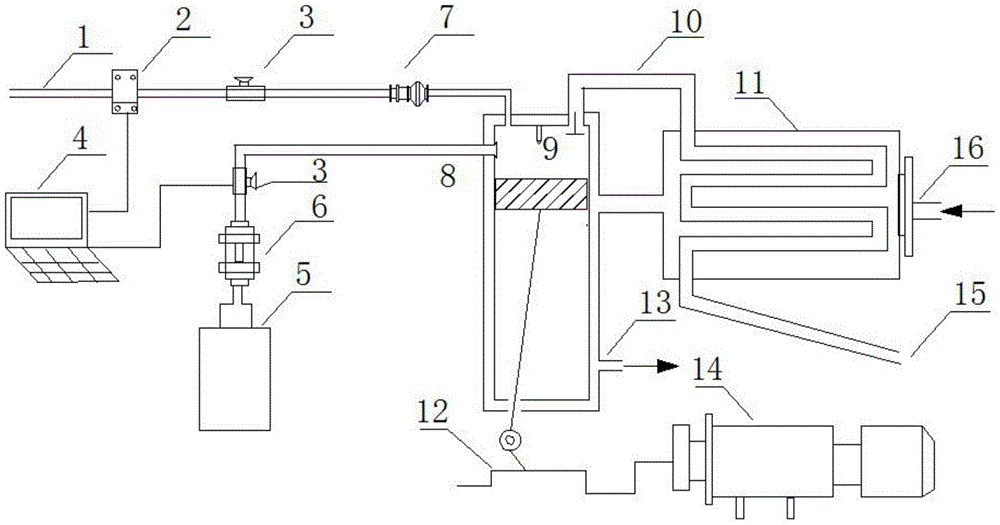

Nuclear powered internal engine nuclear fuel cycle and housing design improvement

ActiveUS20180170496A1Stable internal performanceImprove performanceCosmonautic vehiclesInternal combustion piston enginesWorking fluidChemical composition

A nanofuel engine including receiving nanofuel (including moderator, nanoscale molecular dimensions & molecular mixture) internally in an internal combustion engine that releases nuclear energy, is set forth. A nanofuel chemical composition of fissile fuel, passive agent, and moderator. A method of obtaining transuranic elements for nanofuel including: receiving spent nuclear fuel (SNF); separating elements from SNF, including a stream of elements with Z>92, fissile fuel, passive agent, fertile fuel, or fission products; and providing elements. A method of using transuranic elements to create nanofuel, including: receiving, converting, and mixing the transuranic elements with a moderator to obtain nanofuel. A method of operating a nanofuel engine loaded with nanofuel in spark or compression ignition mode. A method of cycling a nanofuel engine, including compressing nanofuel; igniting nanofuel; capturing energy released in nanofuel, which is also the working fluid; and using the working fluid to perform mechanical work or generate heat.

Owner:GLOBAL ENERGY RES ASSOC

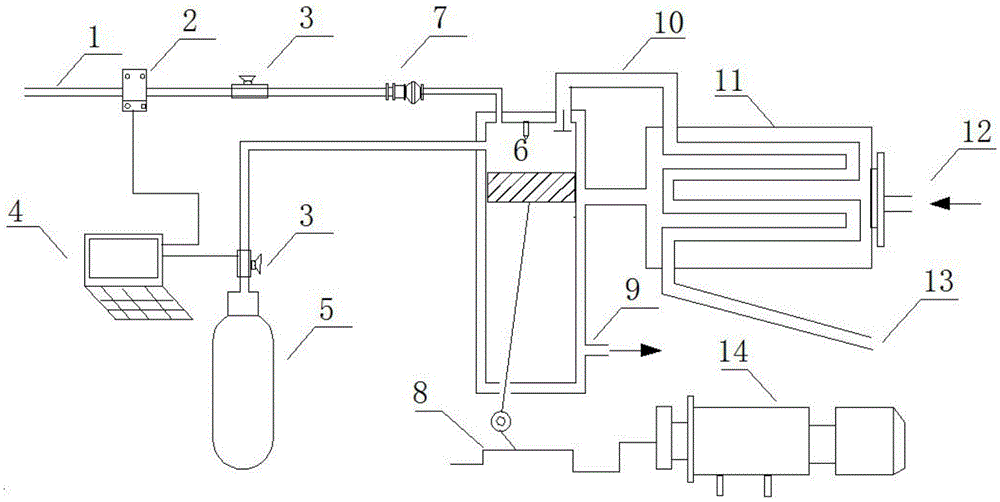

Technique and method for achieving power generation by means of explosion of extremely-low-concentration gas

InactiveCN105649771AInternal combustion piston enginesExhaust apparatusMechanical energyEnergy conversion efficiency

The invention relates to a technique and method for achieving power generation by means of the explosion of extremely-low-concentration gas. According to the method, in order to fully utilize gas with the concentration being lower than the 5% lower explosive limit and particularly mine return air gas with the concentration being lower than 0.75%, combustible and explosive gas or liquid with the optimal volume concentration is sprayed into the gas, and the combustible and explosive gas or liquid with the optimal volume concentration is relatively cheap and easy to store and transport; in addition, the combustible and explosive gas or liquid has a low lower explosive limit and can be ignited to explode after being mixed with the extremely-low-concentration gas, then acting is achieved for generating mechanical energy, a piston drives a crankshaft connecting rod to be connected with a power generator so that the mechanical energy can be converted into electric energy, and waste heat is recycled. The technique comprises a gas delivering and drying system, a liquid atomization system, a gas distribution system, a cooling system, a waste heat utilization system, a heat engine system and a power generation system. According to the technique and method for achieving power generation by means of the explosion of the extremely-low-concentration gas, the gas with the concentration being lower than 5% can be fully utilized, the energy conversion efficiency is improved, and greenhouse gas emission is reduced; and a novel energy-saving and emission-reducing power generation method is provided.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

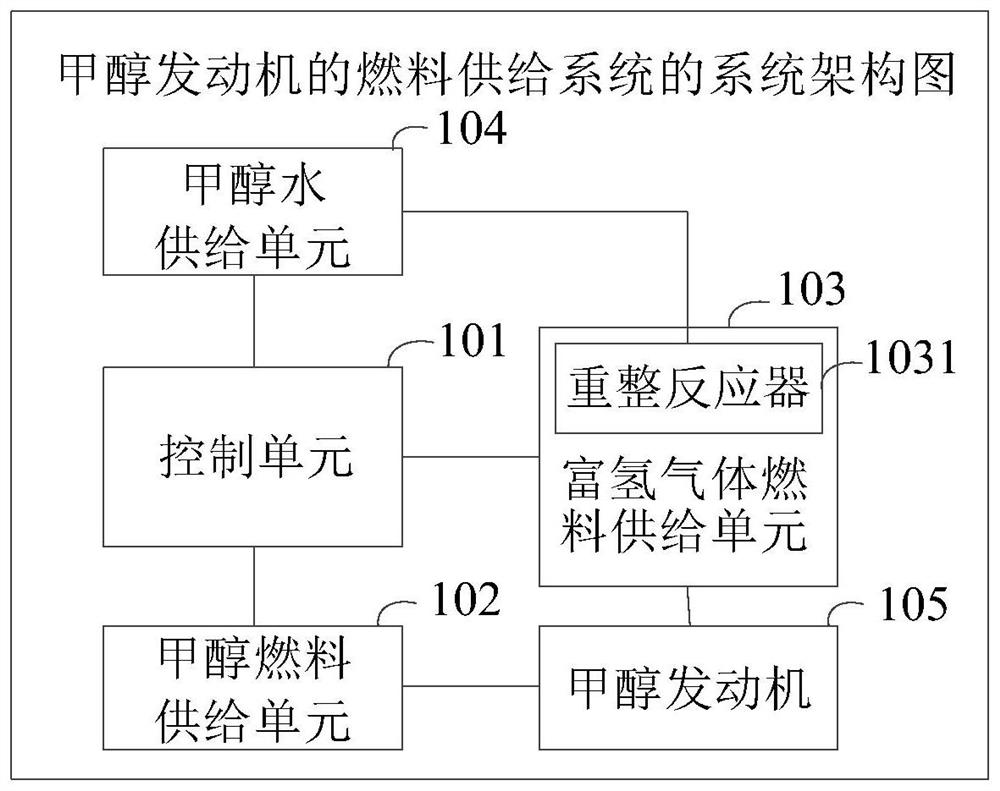

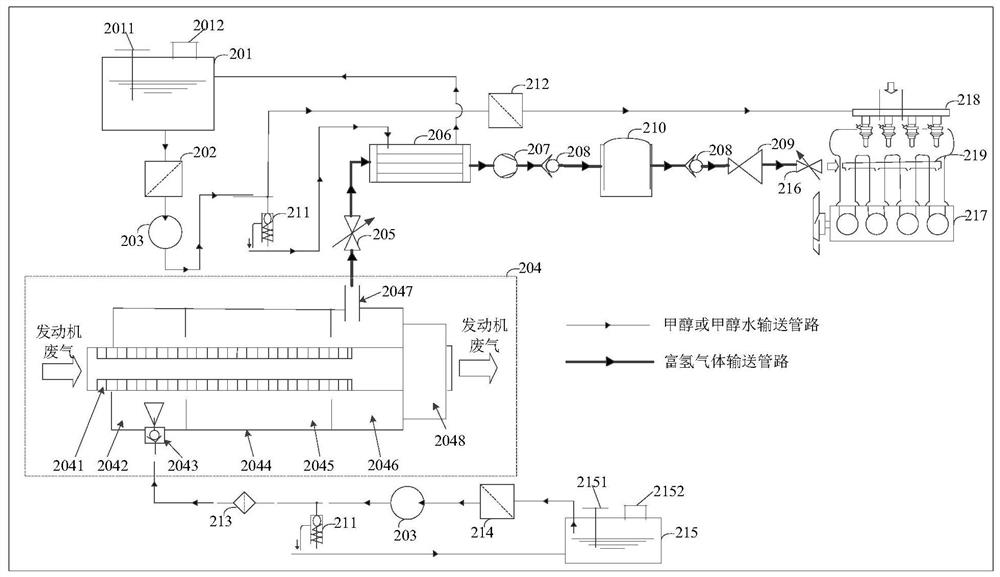

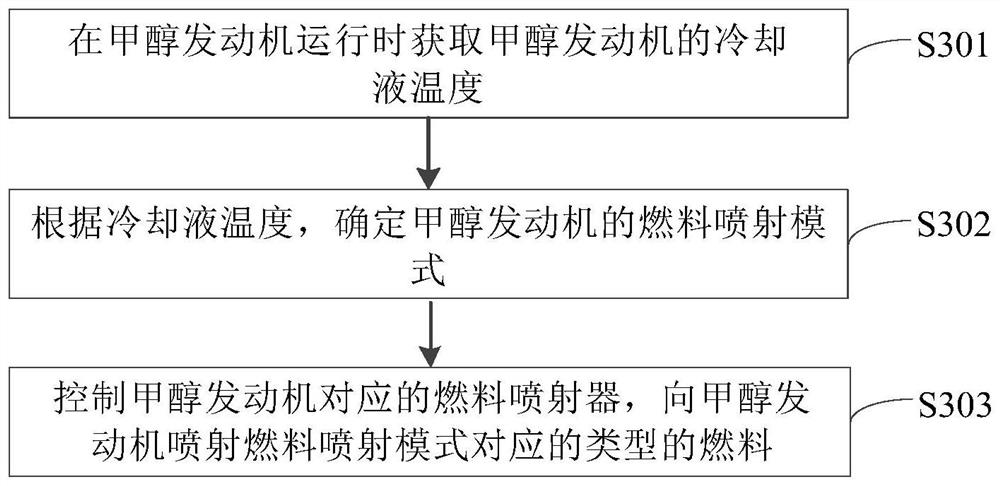

Fuel supply method, device and system of methanol engine

PendingCN114687873AHigh thermal efficiencyImprove combustion qualityElectrical controlInternal combustion piston enginesCoolant temperatureCooling fluid

The invention provides a fuel supply method, device and system for a methanol engine. The fuel supply method comprises the steps that firstly, the cooling liquid temperature of the methanol engine is obtained when the methanol engine operates; then, according to the temperature of the cooling liquid, the fuel injection mode of the methanol engine is determined; and then, a fuel injector corresponding to the methanol engine is controlled, and fuel of the type corresponding to the fuel injection mode is injected to the methanol engine. Through the mode, the type of the fuel injected to the methanol engine can be determined according to the temperature of the cooling liquid of the methanol engine, so that the fuel combustion quality of the methanol engine is improved, and the heat efficiency of the methanol engine is improved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Gasoline-diesel complex combustion engine

InactiveCN106870115AElectrical controlInternal combustion piston enginesCombustion chamberGasoline fuel

A gasoline-diesel complex combustion engine may include a cylinder including a cylinder body in which a combustion chamber is formed to generate a driving power by combusting a gasoline fuel and a diesel fuel and a cylinder head formed to cover an upper portion of the cylinder body, a pair of intake ports formed in the cylinder head, a pair of exhaust ports formed in the cylinder head, a diesel injector disposed in a center of the cylinder head, a pair of spark plugs disposed on opposite sides of the diesel injector, a first intake pipe and a second intake pipe mounted in the intake ports, an exhaust pipe mounted in the exhaust ports, a pair of intake valves disposed in the first and second intake pipes, and a gasoline injector disposed in the first and second intake pipes to inject the gasoline fuel into the combustion chamber.

Owner:HYUNDAI MOTOR CO LTD

Variable compression ratio internal combustion engine

The invention is directed to a variable compression ratio internal combustion engine in which the compression ratio of the engine can be varied and multiple types of fuels having different combustion velocities are used. The invention provides a technology for achieving excellent engine performance for respective types of fuels. In the variable compression ratio internal combustion engine in which the compression ratio can be varied and multiple types of fuels having different combustion velocities are injected through multiple fuel injection valves, maps from which a target compression ratio of the internal combustion engine is read out are switched in accordance with the fuel used, thereby suppressing knocking or other disadvantages.

Owner:TOYOTA JIDOSHA KK

Heat energy recovery internal combustion engine

PendingCN114508413AIncrease workImprove work efficiencyFuel cell heat exchangeInternal combustion piston enginesCombustion chamberFuel cells

The invention provides a heat energy recovery internal combustion engine. The device comprises a combustion chamber, an air inlet channel, a spark plug, an air pressure supplementing cavity and a hydrogen inlet channel. According to the internal combustion engine, in the air inlet process of the air piston, hydrogen exhausted by the vehicle-mounted fuel cell is synchronously injected into the combustion chamber through the hydrogen inlet channel, so that the hydrogen is mixed with gasoline; and at the later stage of the air inlet process of the air piston, part of mixed gas in the combustion chamber is pumped out through suction of the piston in the air pressure supplementing cavity and temporarily stored in the air pressure supplementing cavity to serve as supplementary fuel in the acting combustion process of the combustion chamber. After the piston reaches the peak position of the compression stroke, the mixed gas is supplemented into the combustion chamber until the spark plug ignites to block the air pressure adjusting hole so as to trigger the combustion chamber to ignite the mixed fuel under high pressure, so that the conversion efficiency of the fuel is improved, and the acting of the internal combustion engine in the single stroke is improved.

Owner:NANJING INST OF MECHATRONIC TECH

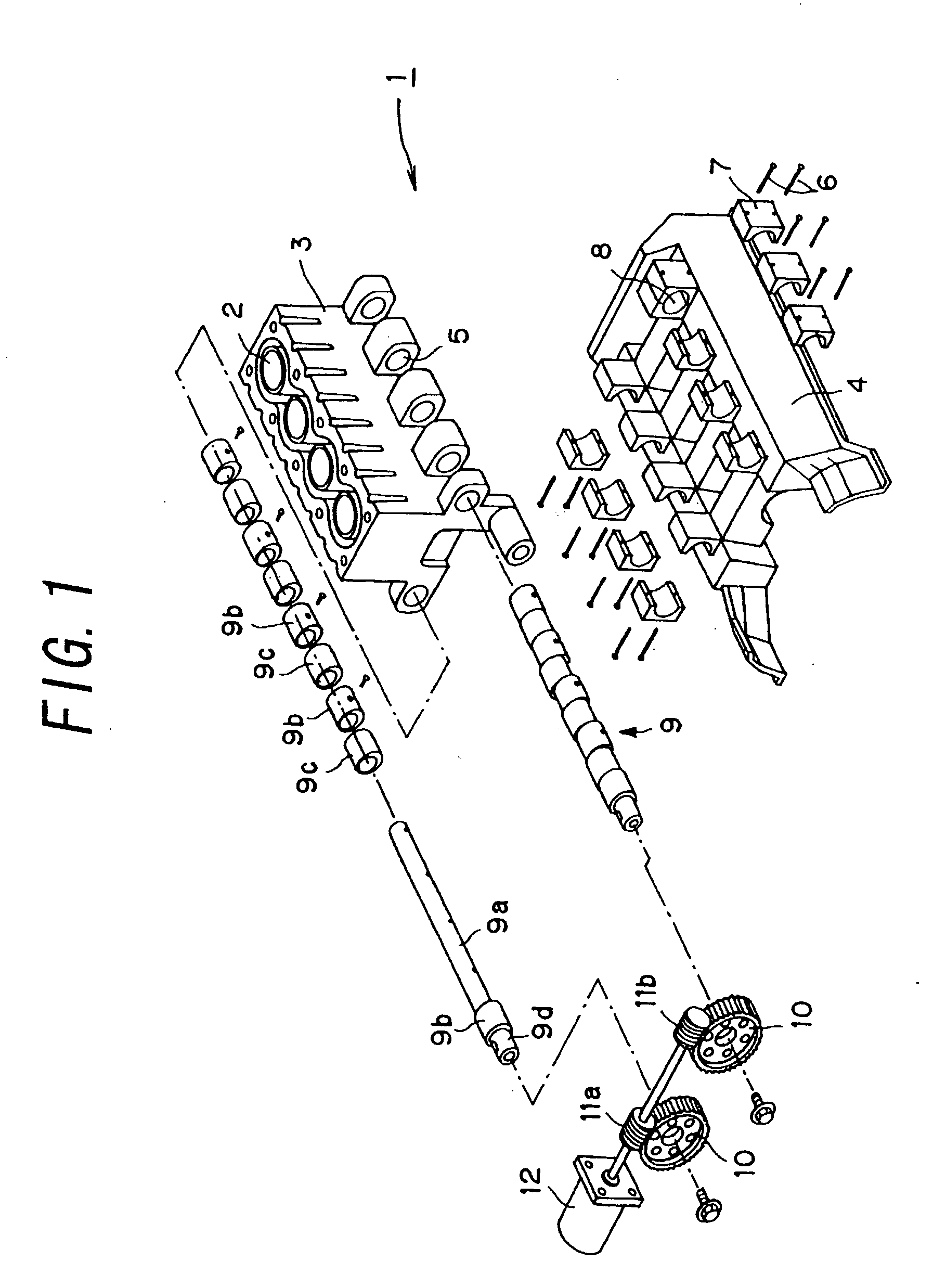

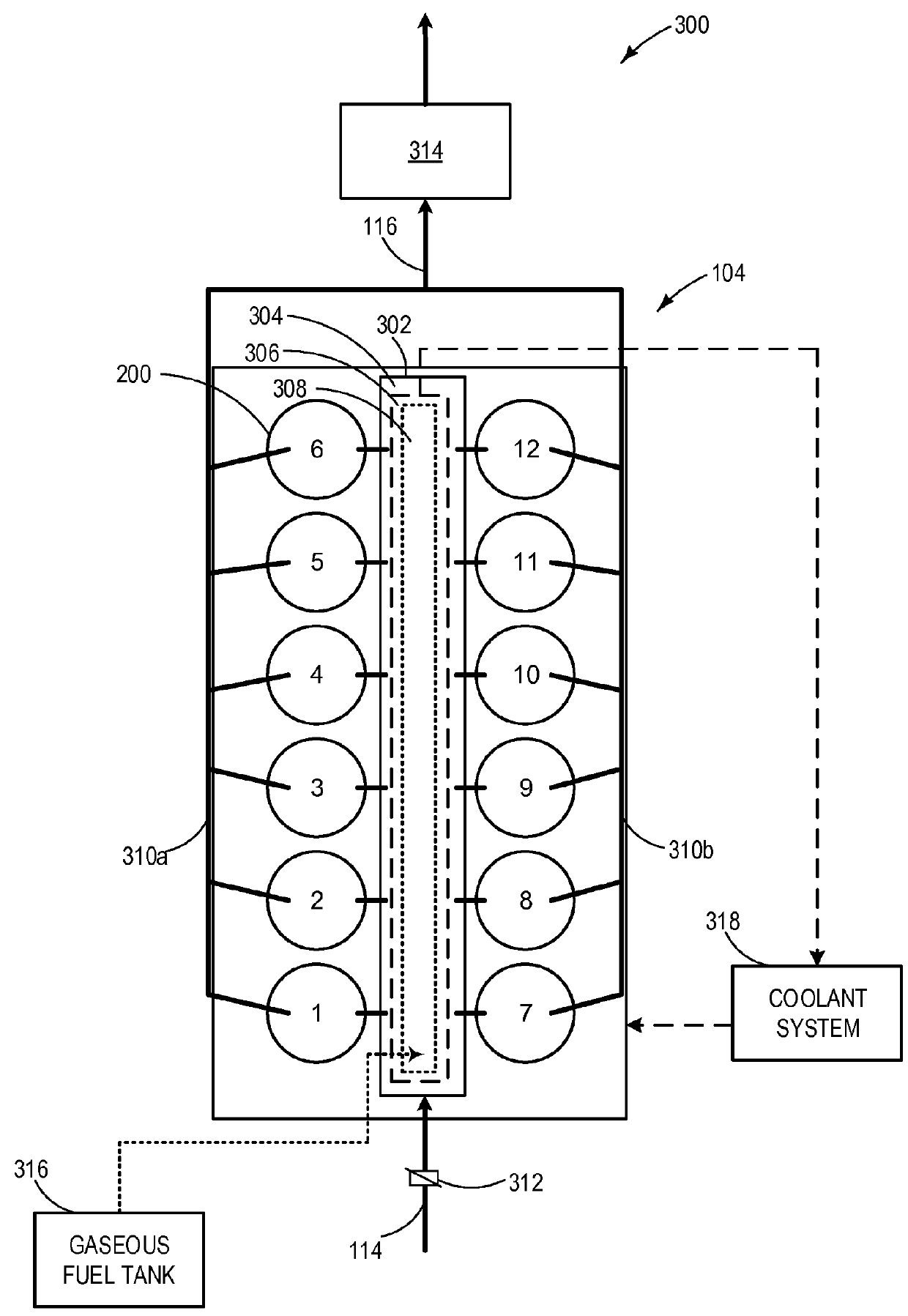

Multi-fuel engine system

Various methods and systems are provided for an intake manifold for an engine. In one example, an insert comprises an annular body having a top surface, bottom surface, inner surface, and outer surface. The insert further comprises a first groove for coupling an intake air port of an intake manifold to a cylinder head, a second groove for circulating gaseous fuel received from a gas runner of the intake manifold, and one or more openings to fluidically couple the second groove to an interior of the intake air port. The insert is configured to mix gaseous fuel and intake air at a coupling location between the intake manifold and the cylinder head.

Owner:GE GLOBAL SOURCING LLC

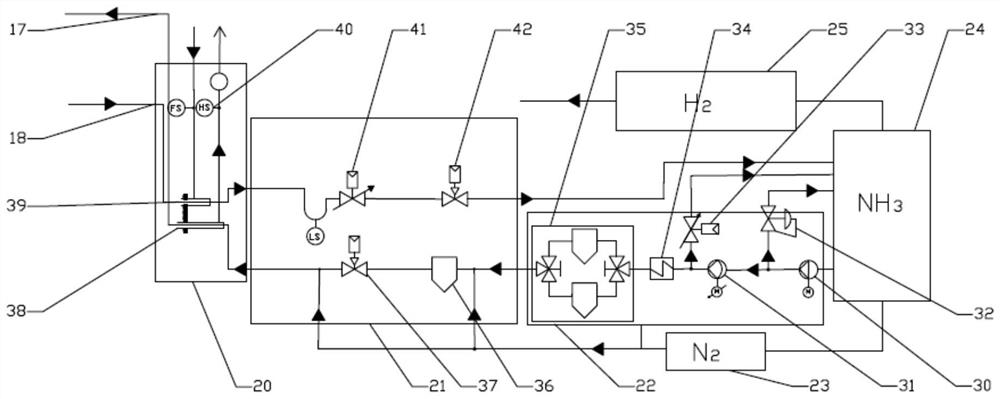

Liquid ammonia phase change cooling type hybrid power thermal management system

ActiveCN114151252AControl injectionSave installation spaceLiquid coolingHeat pumpsFuel oilThermal management system

The invention aims to provide a liquid ammonia phase change cooling type hybrid power thermal management system which comprises an ejector, a liquid ammonia hydrogen supply system, a liquid ammonia common rail pipe, a fuel oil common rail pipe and an oil tank, and the liquid ammonia hydrogen supply system comprises a liquid ammonia storage tank, an ammonia pumping system, a flow dividing system and an ammonia inlet and outlet system. The fuel oil common rail pipe is connected with the oil tank and a one-way oil inlet of the ejector, the liquid ammonia common rail pipe is connected with the ammonia inlet and outlet system and a one-way ammonia inlet of the ejector, an ammonia inlet pipe and an ammonia return pipe are arranged in the ammonia inlet and outlet system, and the ammonia pumping system comprises a liquid ammonia storage flow divider, a low-pressure pump and a high-pressure pump. The flow dividing system comprises a storage tank, an ammonia inlet control valve, a safety valve and an ammonia outlet control valve. The cold start problem of the engine under the cold condition can be effectively solved, the power consumption of the compressor is reduced, waste heat utilization is achieved, and the energy utilization rate is increased. Meanwhile, a feasible ammonia fuel application path is provided, and three purposes of one ammonia fuel are achieved.

Owner:HARBIN ENG UNIV

Multi-fuel engine system

Owner:GE GLOBAL SOURCING LLC

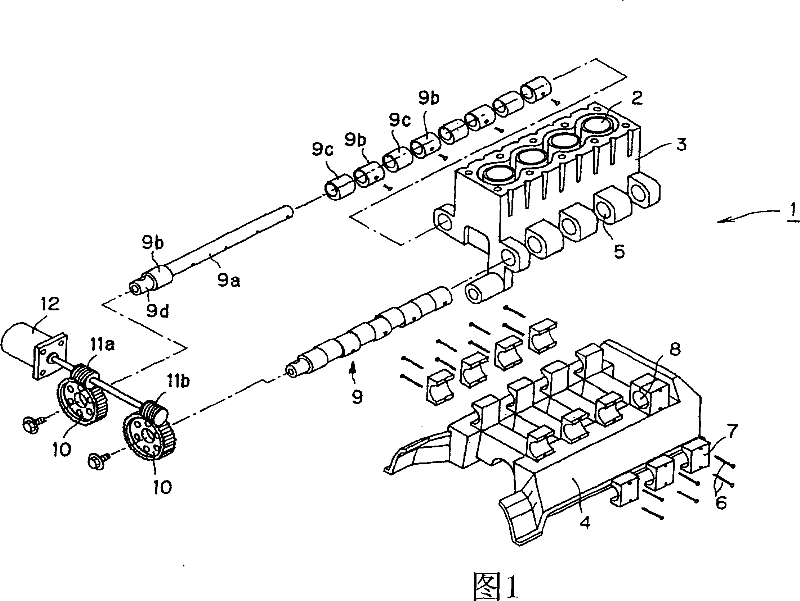

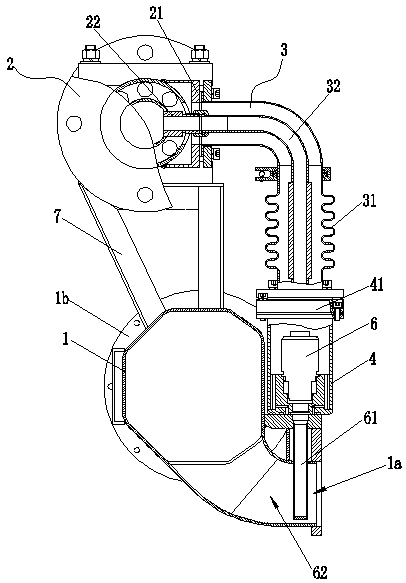

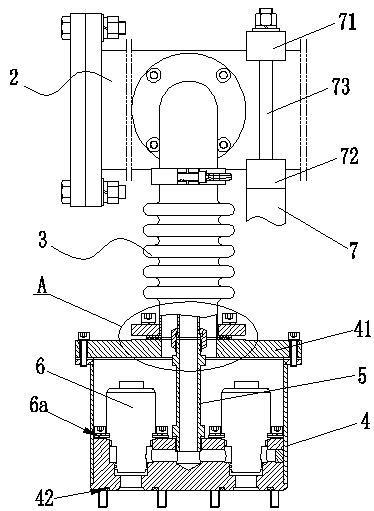

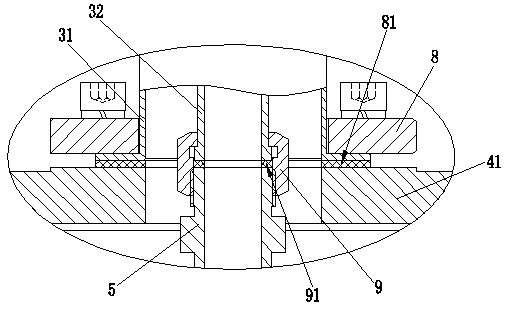

Air intake structure of a dual-fuel engine

ActiveCN105484864BAchieve overlayRetrofit smallInternal combustion piston enginesFuel supply apparatusEngineeringInlet manifold

The invention discloses an air inlet structure for a dual-fuel engine. The air inlet structure comprises an air inlet pipe and a fuel air inlet manifold. The fuel air inlet manifold is connected with a valve piece box through a fuel air inlet branch pipe. The fuel air inlet manifold comprises an outer air inlet manifold body and an inner air inlet manifold body. The fuel air inlet branch pipe comprises an outer air inlet branch pipe body and an inner air inlet branch pipe body. One end of the outer air inlet branch pipe body is connected with the outer air inlet manifold body, and the other end of the outer air inlet branch pipe is connected with a cover plate of the valve piece box. One end of the inner air inlet branch pipe body is connected with the inner air inlet manifold body, and the other end of the inner air inlet branch pipe body is connected with a fuel gas inlet connecting pipe extending in the valve piece box. At least one fuel gas jetting valve communicated with the inner air inlet branch pipe body is arranged in the valve piece box, wherein a nozzle is arranged on the fuel gas jetting valve and extends in the air inlet pipe. The air inlet structure for the dual-fuel engine has the advantages of being simple and compact in structure, safe, reliable and high in combustion efficiency, and therefore the energy utilization rate is increased.

Owner:NINGBO C S I POWER & MASCH GRP CO LTD

A Safety Monitoring System for Marine LNG/Diesel Dual Fuel Engine

InactiveCN107035521BEasy to analyzeEasy to handleInternal combustion piston enginesEngine controllersGas detectorUSB

The invention discloses a marine LNG / diesel oil dual-fuel engine safety monitoring system. A central control room control cabinet serves as a core of an overall system, an industrial personal computer in the central control room control cabinet is connected with a programmable logic controller, a fuel gas alarming controller, an LNG air storage tank communication module, a thermocouple collecting module and a serial port relay module which are arranged in an on-site control cabinet through a USB-to-RS485 converter. The programmable logic controller in the on-site control cabinet is connected with a rotating speed sensor, a temperature sensor, a pressure sensor, a flame detector and an interlocking gas valve. The fuel gas alarming controller module is connected with a fuel gas detector. The LNG air storage tank communication module is connected with a gas tank pressure and liquid level sensor. The thermocouple collecting module is connected with an air cylinder exhaust temperature sensor. A real-time and accurate safety monitoring data report can be provided, analysis and treatment on the LNG / diesel oil dual-fuel engine system in the later period are facilitated, and the safety monitoring system can be conveniently used for engines in different types and different monitoring schemes.

Owner:WUHAN UNIV OF TECH

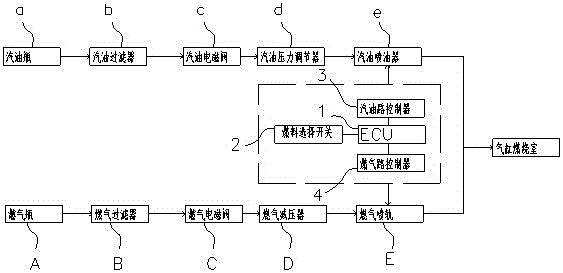

Multi-fuel electronic injection engine for forklift

InactiveCN105756785AIncrease inspiratory capacitySafe and reliable workElectrical controlInternal combustion piston enginesCombustion chamberIgnition coil

The invention relates to the field of forklift engines, in particular to a multi-fuel electronic injection engine for a forklift.The multi-fuel electronic injection engine comprises a fuel feeding system for feeding gasoline or natural gas to an engine cylinder combustion chamber and an electronic control system for controlling feeding of gasoline and feeding of natural gas fuel to the engine.When the gasoline is fed, a corresponding gasoline nozzle is opened, meanwhile, a corresponding ignition coil of the cylinder combustion chamber starts to ignite, and air synchronous with injection gasoline enters an electronic throttle valve, and then enters the cylinder combustion chamber through an air intake manifold to allow the engine to operate; when gas is fed, a corresponding gas nozzle is opened, meanwhile, a corresponding ignition coil of the cylinder combustion chamber starts to ignite, and air synchronous with injection gas enters the electronic throttle valve, and then enters the cylinder combustion chamber through the air intake manifold to allow the engine to operate; the electronic throttle valve is arranged on the air intake manifold, adjusts the opening degree of a speed-limiting throttle valve body and limits the opening speed of the throttle valve body.

Owner:合肥宝发动力技术股份有限公司

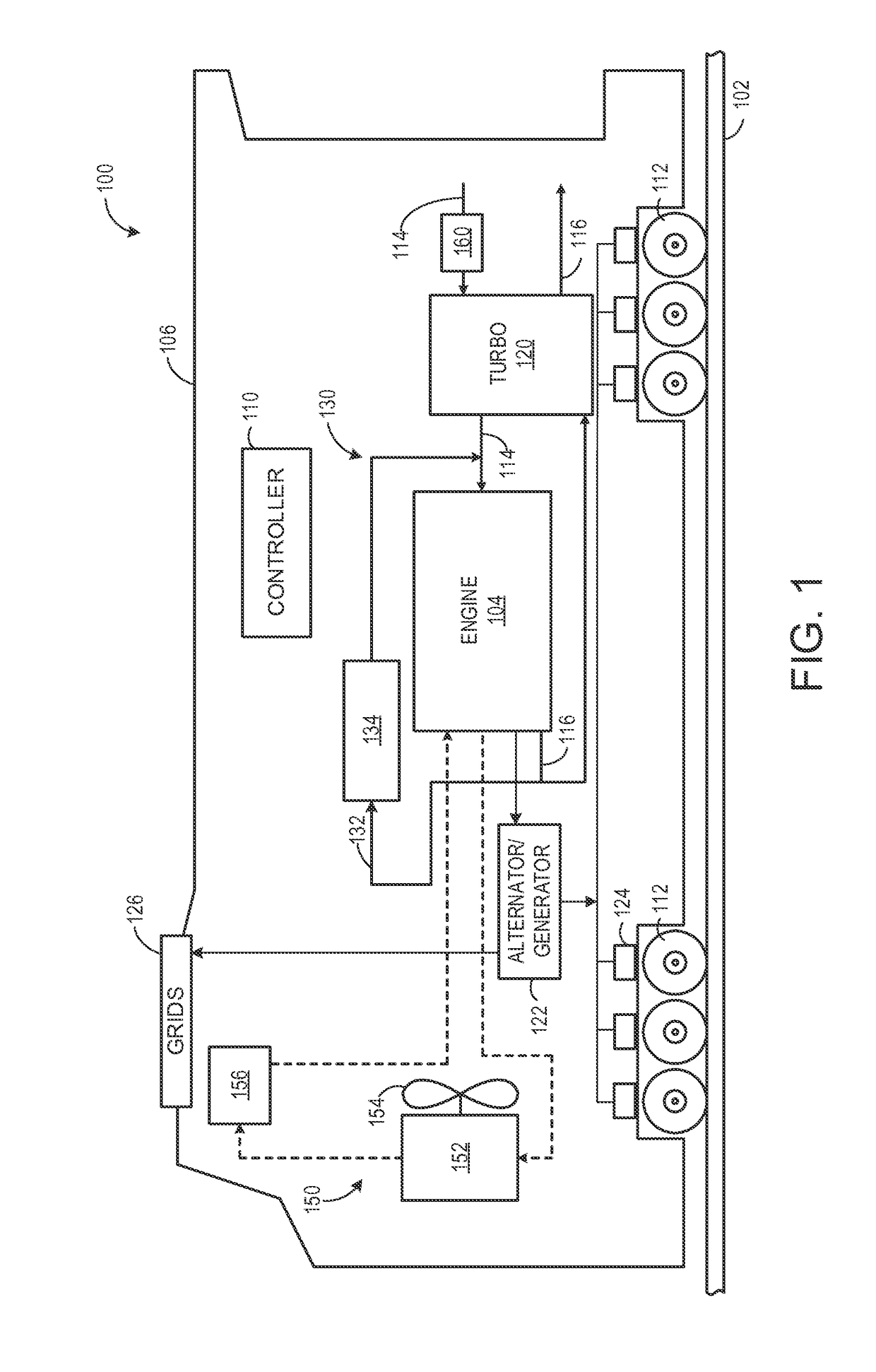

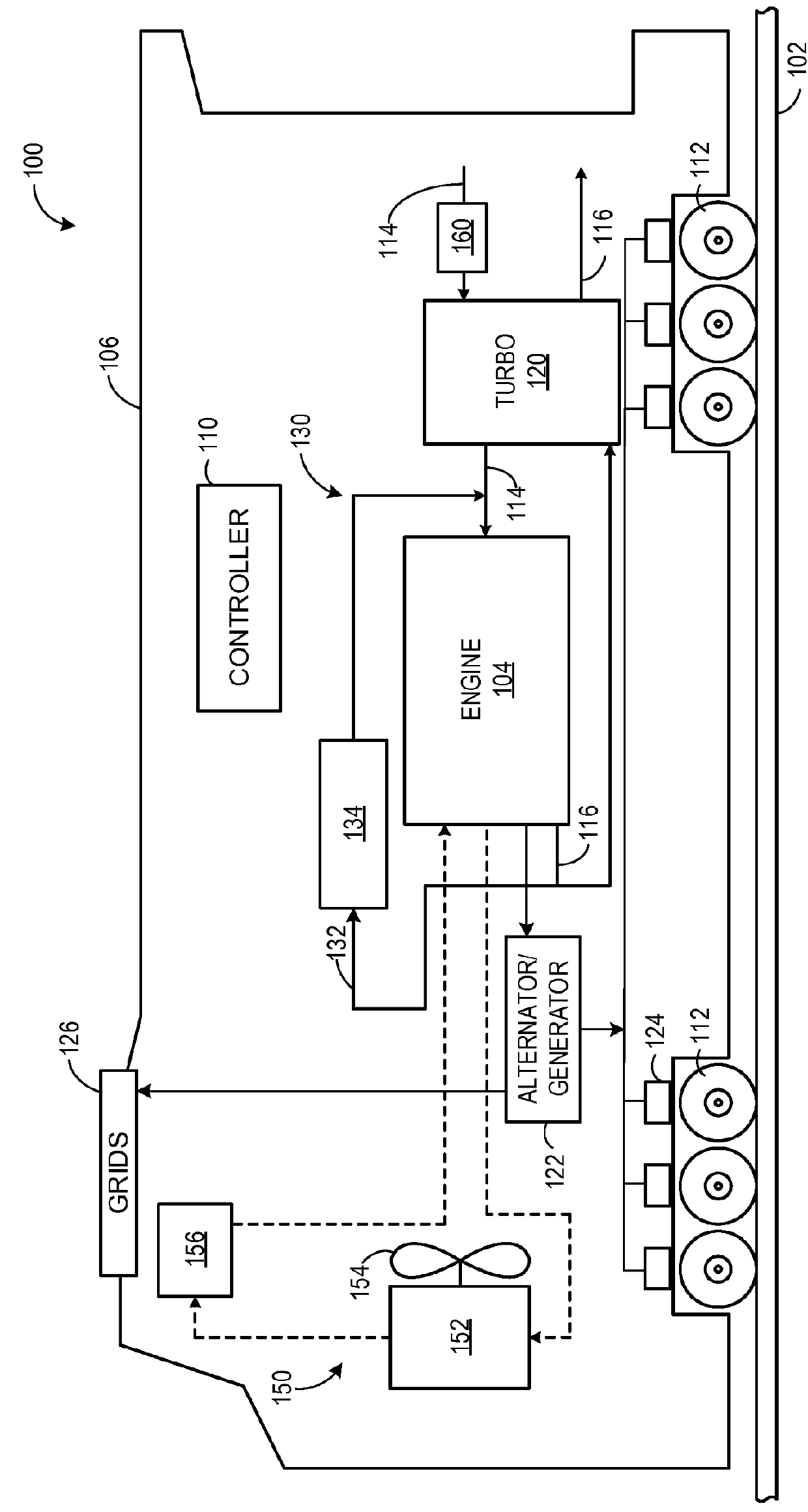

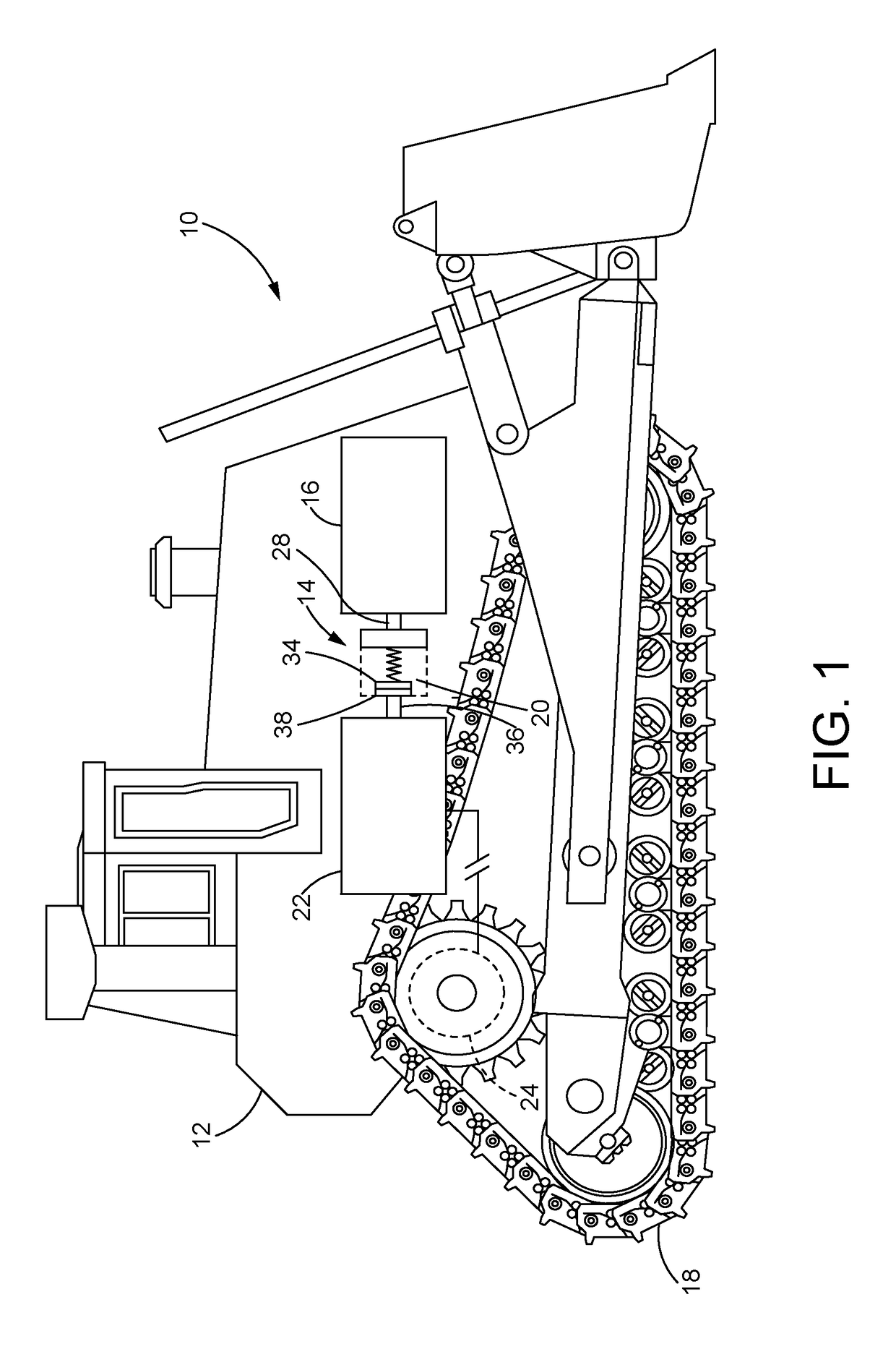

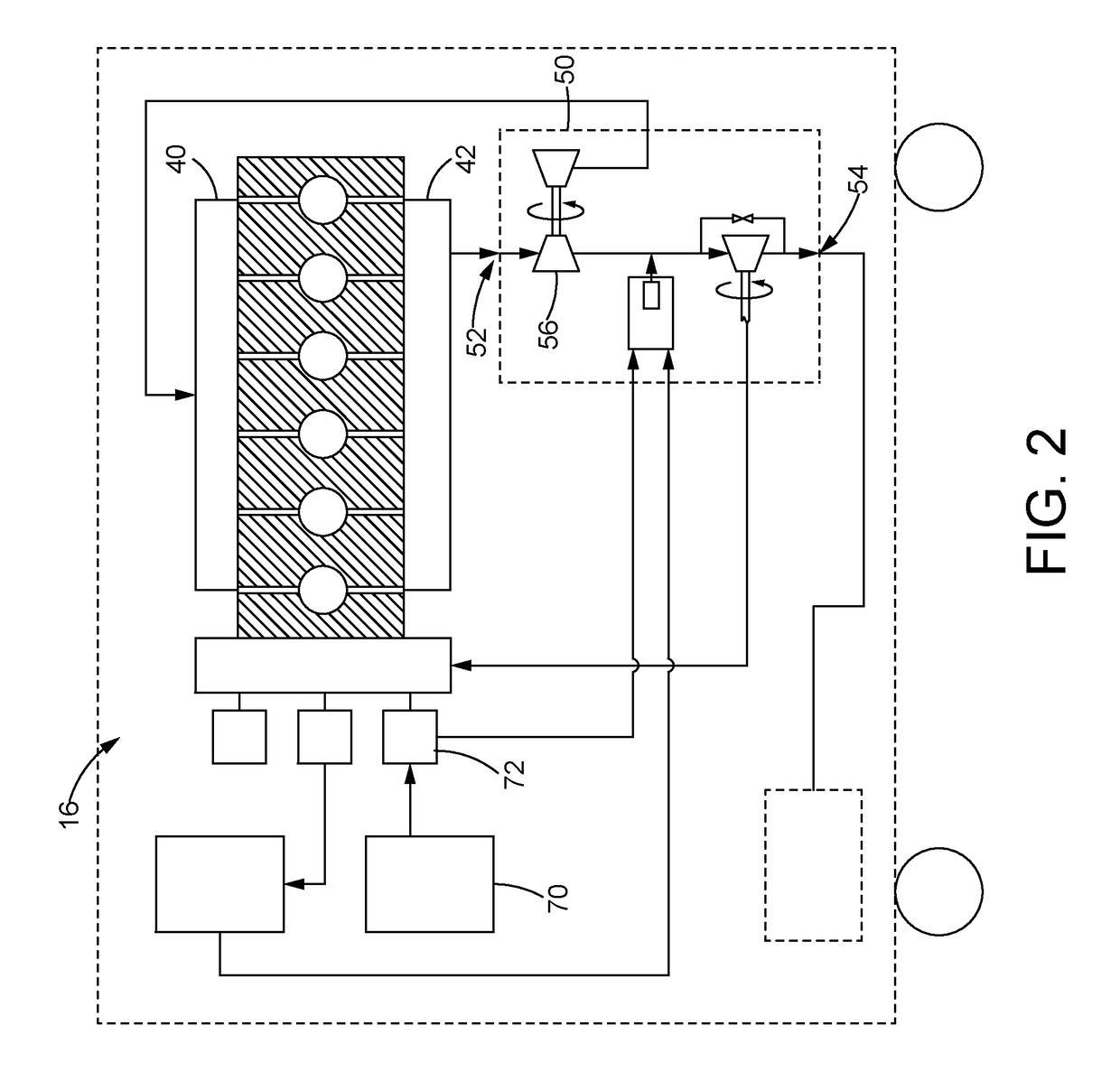

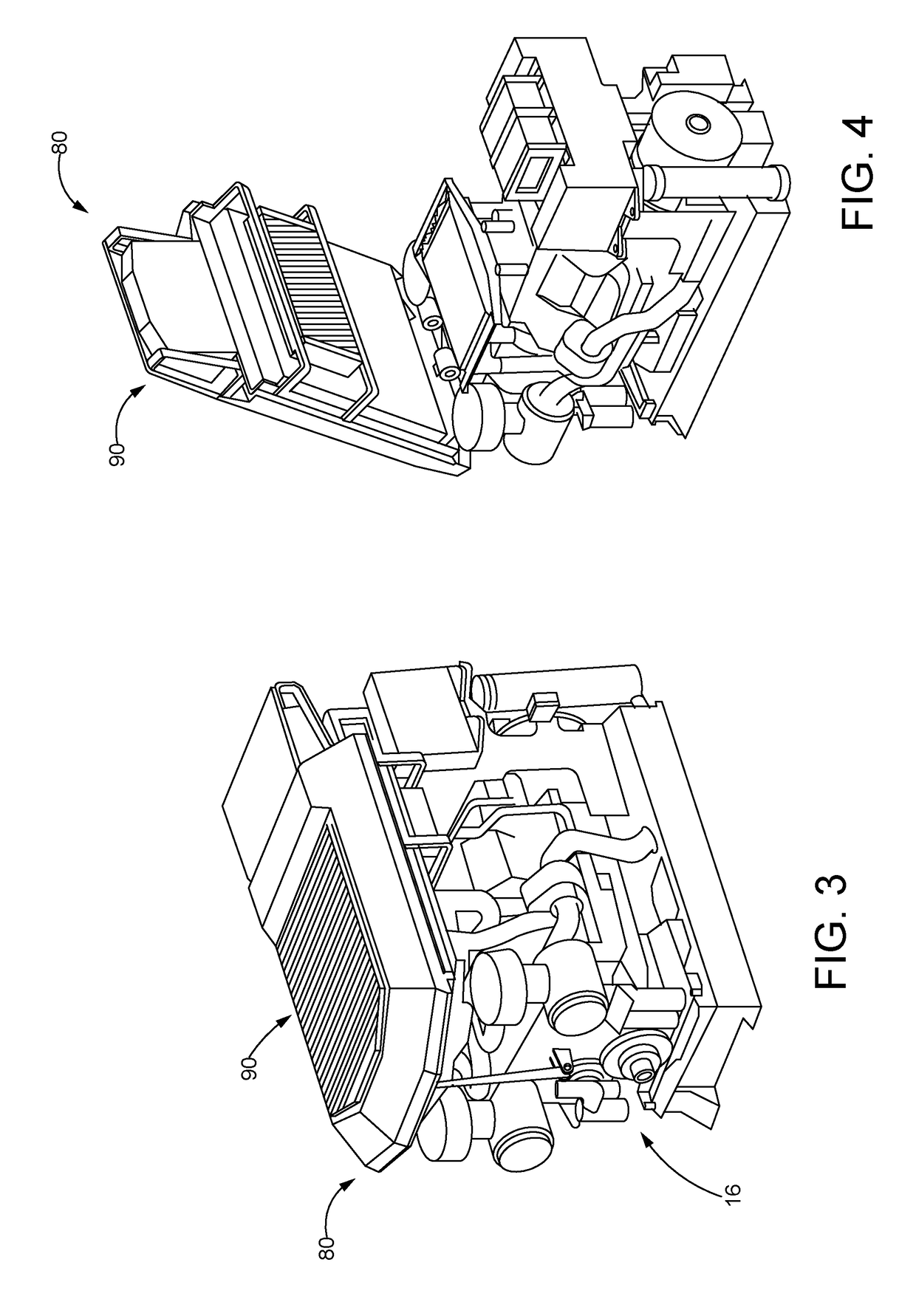

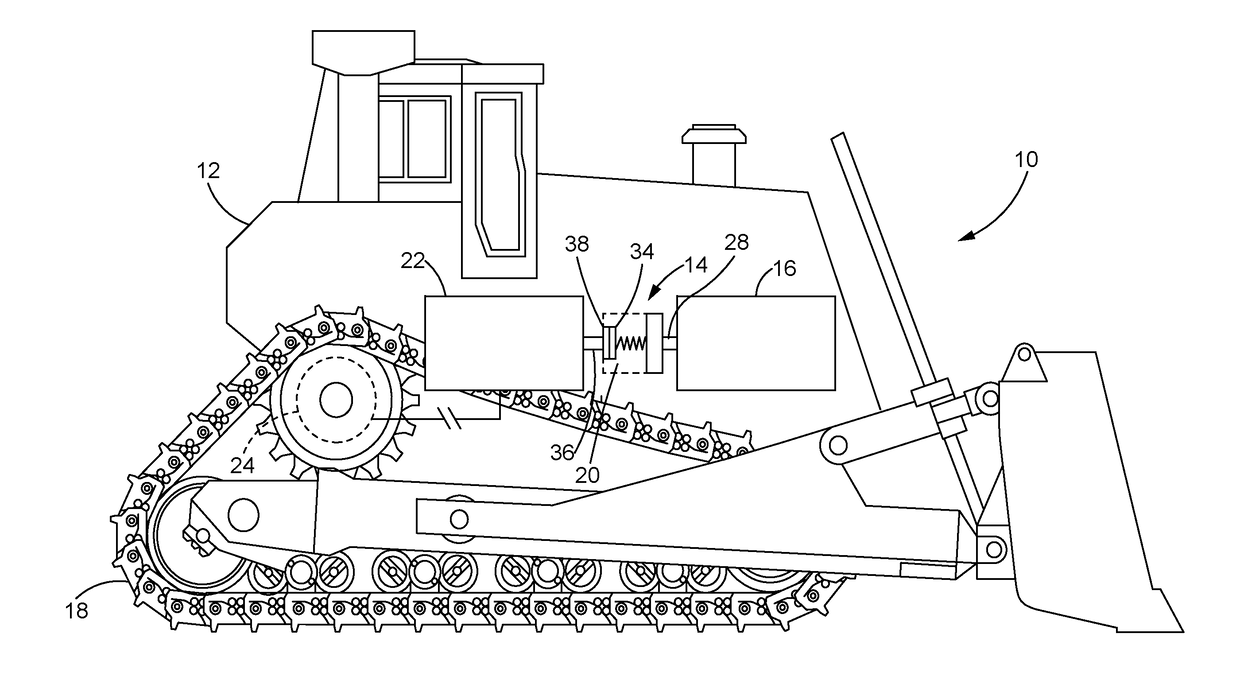

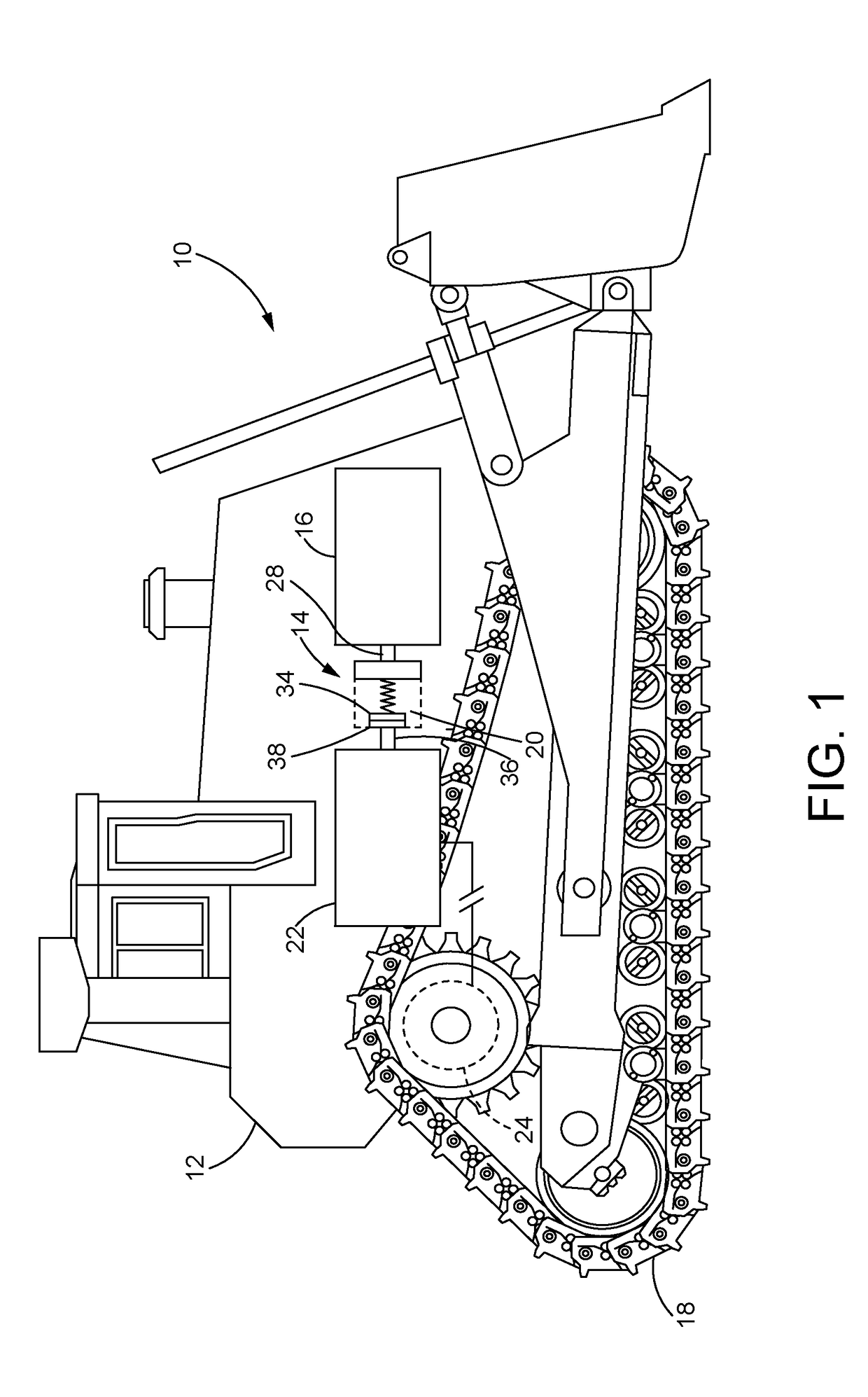

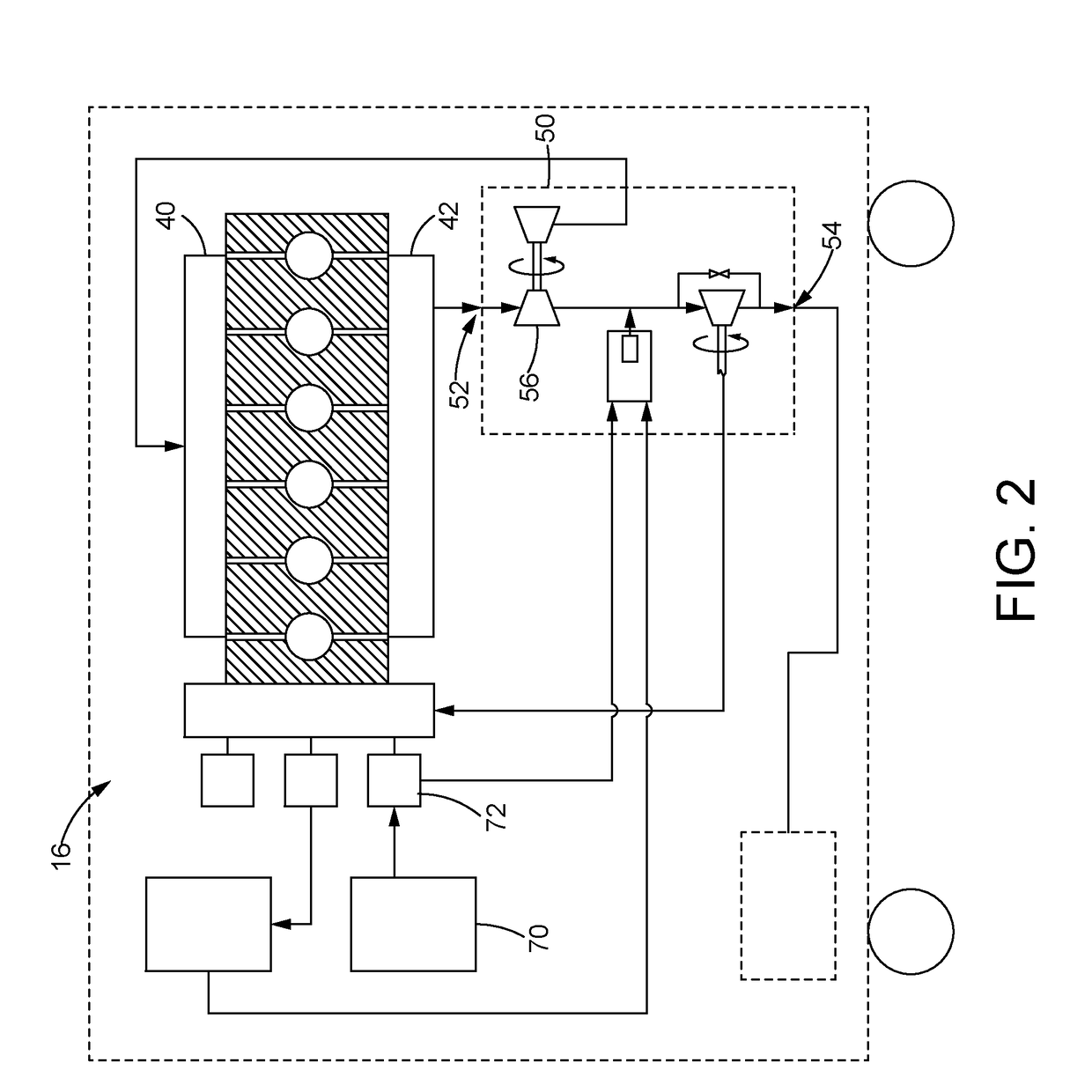

Modular power unit

ActiveUS10196966B2Internal combustion piston enginesNuclear energy generationElectrical batteryEngineering

A work machine is provided. The work machines may include a power module configured to provide power including a battery and an engine and configured to a folding heat exchange device. The work machine may also include a drive module configured with one or more motors and positioned over a track roller frame. The work machine may also include a hydraulic module including one or more devices in a front region and one or more devices in a rear region to cut or rip encountered material

Owner:CATERPILLAR INC

Fuel feed system for multi-fuel variable-frequency generator

InactiveCN105952530AImprove performanceImprove stabilityInternal combustion piston enginesFuel injecting pumpsThrottle controlSolenoid valve

The invention discloses a fuel feed system for a multi-fuel variable-frequency generator. The fuel feed system comprises a fuel gas feed module, a gasoline feed module and an oil-gas transformation control module. The oil-gas transformation control module comprises a multi-fuel carburetor (9), a normally-open solenoid valve (8), a direct current stabilizer (7), a solenoid valve microswitch (5) and a flameout microswitch (17). A valve needle (31) of the normally-open solenoid valve (8) is matched with an oil extraction hole (30) of an oil cup (29). A boss (22) of a fuel gas switch handle (3) is matched with a warping plate (21) of the solenoid valve microswitch (5). A throttle control rod (14) is provided with a throttle shifting fork (24) and a reset spring (15). A gasoline switch handle (18) is provided with a handle shifting fork (25). When a gasoline switch (16) is turned on, the handle shifting fork (25) is matched with the throttle shifting fork (24); and when the gasoline switch (16) is turned off, the handle shifting fork (25) is matched with a warping plate (23) of the flameout microswitch (17). By means of the structure, the fuel feed system for the multi-fuel variable-frequency generator has the characteristics of being modularized in structure, easy and convenient to operate, smooth and steady in oil-gas switching, free of external power sources, good in stability and the like.

Owner:ZHEJIANG ZHONGJIAN TECH

A methanol engine system using methanol to produce hydrogen as an igniter and an operation method thereof

ActiveCN110273790BAccurate supplyComplete replacementInternal combustion piston enginesNon-fuel substance addition to fuelThermodynamicsProcess engineering

The invention belongs to the technical field of engines, and particularly relates to a methanol engine system adopting methanol to produce hydrogen serving as an ignition agent and an operation method of the methanol engine system. The methanol engine system adopting a two-level heating methanol hydrogen production manner comprises a methanol engine, a gas supply system and an exhaust system, wherein the gas supply system comprises a methanol heater and a methanol hydrogen production device. The invention further discloses the operation method of the methanol engine system. According to the methanol engine system and the operation method of the methanol engine system, methanol-based fuel is adopted for the reaction to generate the hydrogen serving as the ignition agent, ignition agent preparing and stable, continuous and accurate supply to the engine are achieved, and completely replacing the diesel fuel with the methanol-based fuel is achieved under the situation of no need to change the structure of the engine.

Owner:SHENZHEN REVELATION TECH CO LTD

Modular Power Unit

ActiveUS20180172362A1Internal combustion piston enginesNuclear energy generationComputer moduleModularity

A work machine is provided. The work machines may include a power module configured to provide power including a battery and an engine and configured to a folding heat exchange device. The work machine may also include a drive module configured with one or more motors and positioned over a track roller frame. The work machine may also include a hydraulic module including one or more devices in a front region and one or more devices in a rear region to cut or rip encountered material

Owner:CATERPILLAR INC

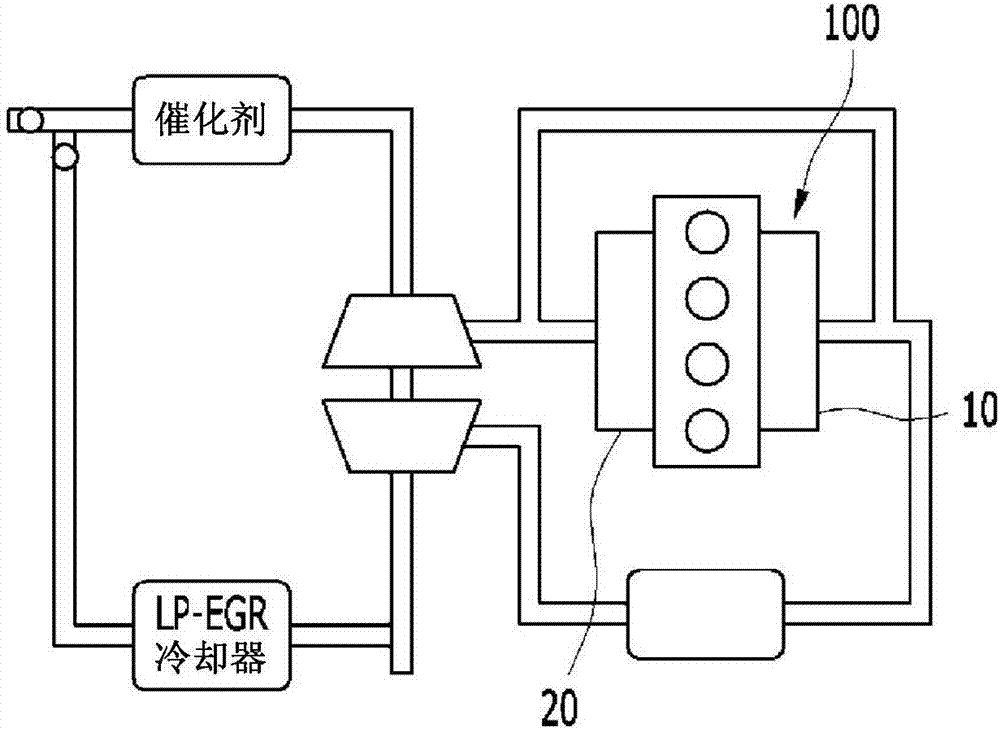

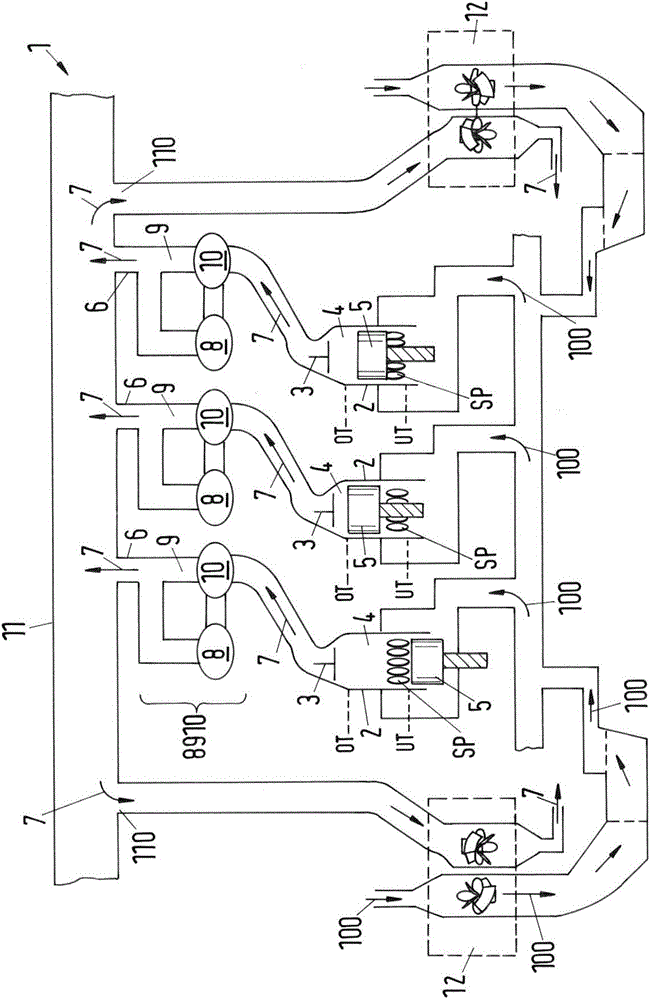

Reciprocating internal combustion engine, exhaust gas conditioning and method for operating a reciprocating internal combustion engine

InactiveCN105089747AReduce methane contentSo as not to damageInternal combustion piston enginesExhaust apparatusExternal combustion engineFour-stroke engine

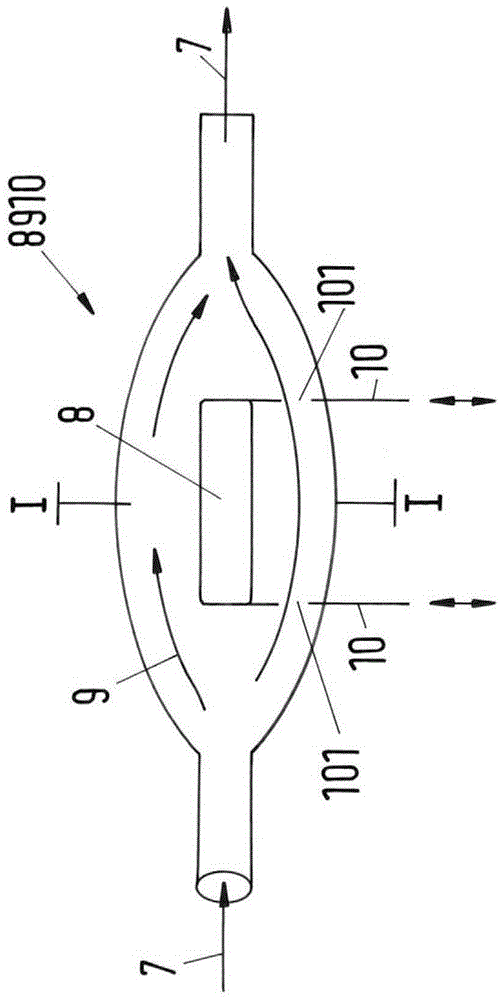

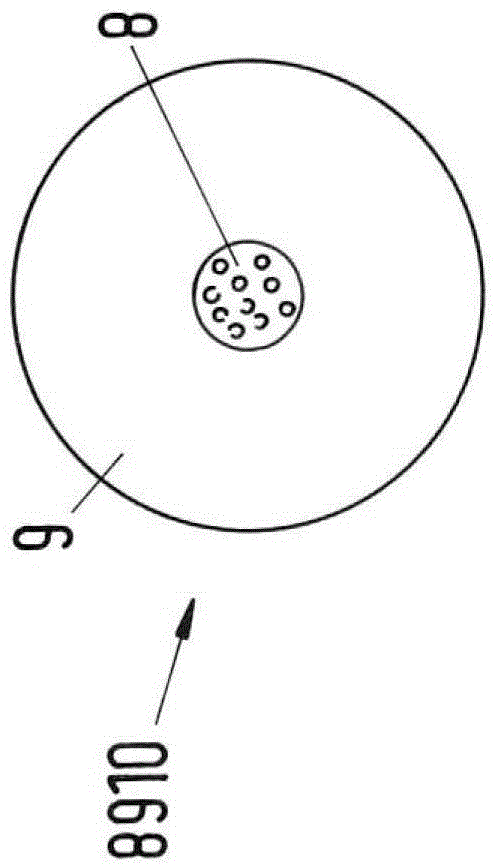

The invention relates to a reciprocating internal combustion engine (1), in particular a two-stroke engine or four-stroke engine, in particular a longitudinally scavenged two-stroke large diesel engine, comprising a cylinder (2) with an outlet valve (3) and a combustion chamber (4) unilaterally limiting piston (5), in the cylinder (2) between an upper dead center (OT) and a bottom dead center (UT) is arranged back and forth. In this case, an exhaust gas line (6) is provided such that an exhaust gas (7) from the combustion chamber (4) via the outlet valve (3) of the exhaust line (6) can be fed .; According to the invention, an exhaust gas treatment (8910) is comprising an exhaust gas catalytic converter (8) and a bypass line (9) and a switching device (10) provided such that the exhaust gas (7) by means of the switching device (10) alternatively through the exhaust gas catalytic converter (8) or on the bypass line (9) from the combustion chamber (4) of the exhaust line (6) can be fed. The invention further relates to an exhaust gas treatment (8910) with exhaust gas catalytic converter (8), bypass line (9) and switching means (10), and a method for operating a reciprocating internal combustion engine.

Owner:WINTERTHUR GAS & DIESEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com