Use of prechambers with dual fuel source engines

A pre-combustion chamber and engine technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., and can solve problems such as low compression ratio and reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

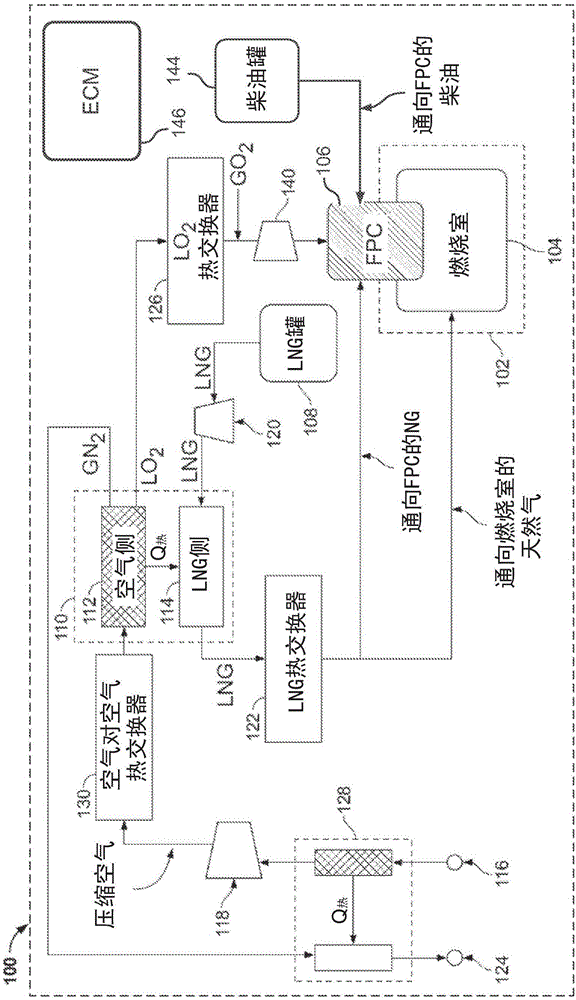

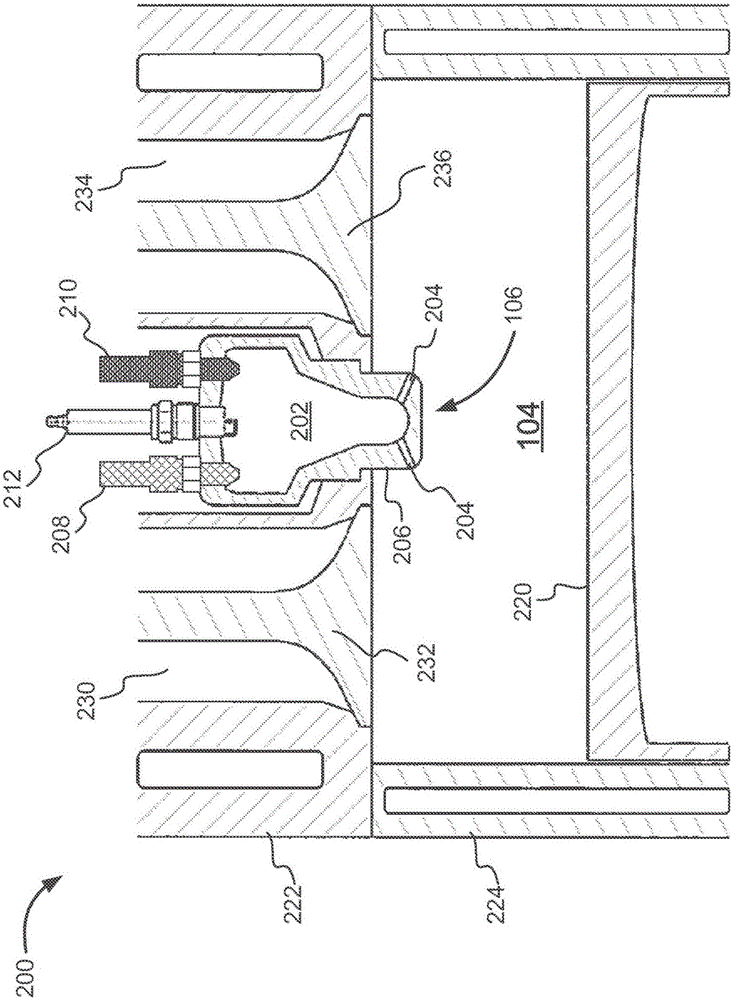

[0033] Figure 1A An example engine 102 is depicted with engine system 100 . The example engine system 100 includes a system that supplies oxygen to the engine 102 . The example engine 102 is a reciprocating piston engine that uses natural gas as fuel, although other engine configurations are within the contemplation of the present invention. Engine system 100 may be incorporated into a skid carrying or associated with engine 102 or a vehicle that may or may not be powered by engine 102 . The engine 102 includes one or more combustors 104 (one shown), each having a feed pre-combustor (FPC) 106 , fed with one or more of liquid fuel, gaseous fuel, and oxygen. In some cases, FPC 106 takes the form of an FPC igniter (eg, a spark plug, laser igniter, hot surface, hot gas, and / or other type of igniter). However, other configurations are also within the contemplation of the present invention.

[0034] The example FPC 106 is configured to receive and ignite one or more gaseous fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com