Reciprocating internal combustion engine, exhaust gas conditioning and method for operating a reciprocating internal combustion engine

An internal combustion engine, reciprocating piston technology, applied in the direction of internal combustion piston engine, combustion engine, exhaust device, etc., can solve the problems of exhaust gas damage, safe and reliable operation of the engine, bubbles, etc., and achieve the effect of reducing the structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

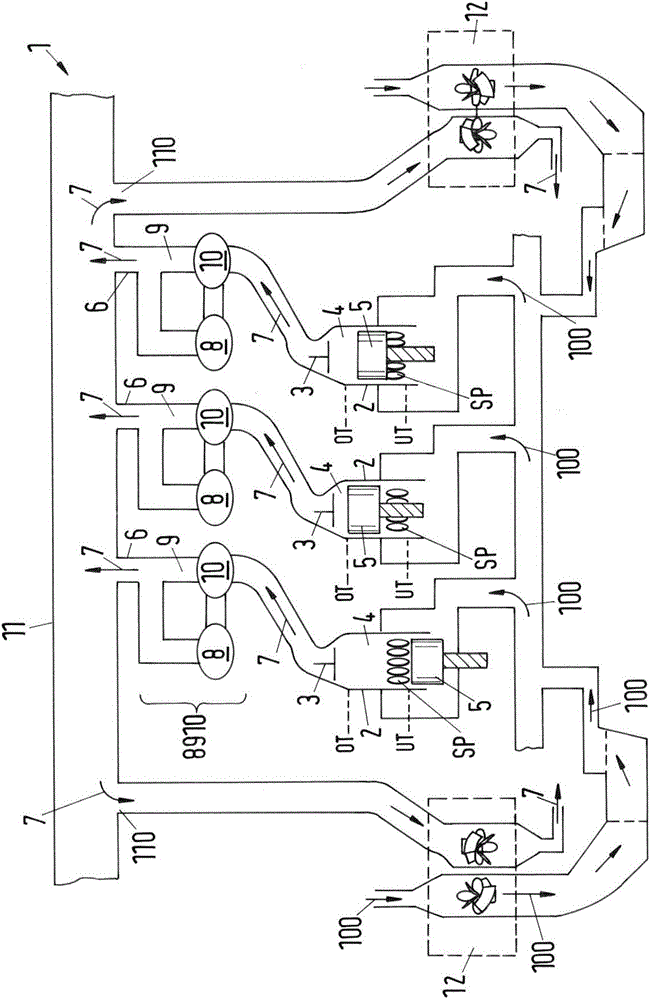

[0035] figure 1 A schematic diagram is shown for explaining the interaction of the basic design of the different components of an engine with an exhaust gas turbocharger system, directed to a specific embodiment of a reciprocating-piston internal combustion engine according to the invention, which is constructed here by way of example is a large two-stroke diesel engine with single-flow scavenging and is designated 1 in its entirety hereinafter.

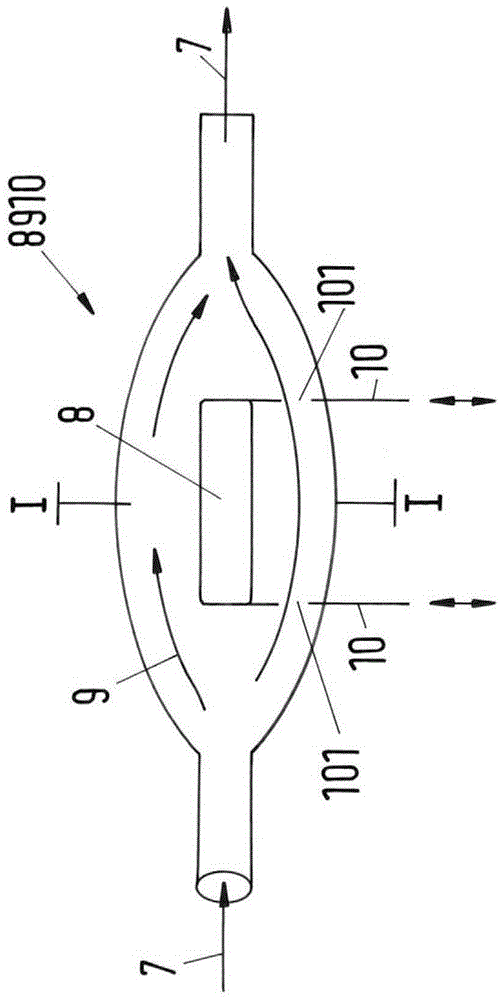

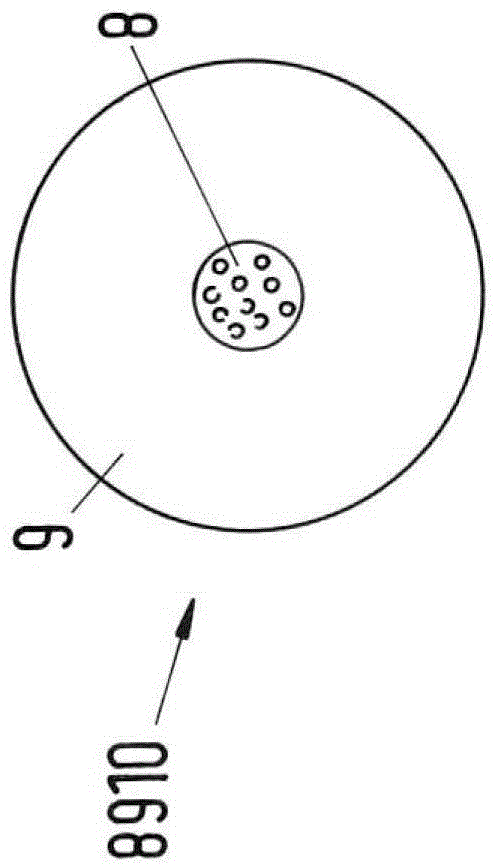

[0036] A large two-stroke diesel engine 1 known per se except for the exhaust gas regulating device 8910 according to the invention generally comprises in practice a plurality of cylinders 2 with outlet valves 3 arranged in the cylinder head and in the cylinders 2, The piston 5 is arranged to be able to move back and forth along the running surface between bottom dead center UT and top dead center OT. The cylinder walls of the cylinder 2 together with the cylinder head and the piston 5 delimit the combustion space 4 of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com