Dry process for detoxicating chromium slag

A process and technology for chromium slag, applied in the field of chromium slag dry detoxification technology and hazardous solid waste disposal, can solve the problems of easy yellowing and high temperature, and achieve the effects of no secondary pollution, overcoming yellowing and low process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

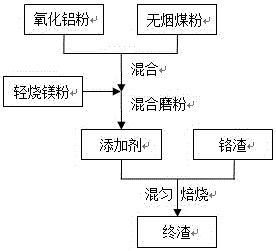

Image

Examples

Embodiment 1

[0023] According to the ratio in Table 1, mix alumina powder and light-burned magnesium powder and grind them together until the particle size is less than or equal to 3mm to make additives, mix the additives with chromium slag evenly, the alkalinity is 1.23, and put them into a vacuum tube furnace to control the reducibility The CO content of the gas is 80~90%, and it is reduced and roasted at 600°C for 30 minutes. The leaching toxicity of hexavalent chromium after the reaction is determined to be 0.130mg / kg, and the leaching toxicity of hexavalent chromium is determined to be 0.137mg after being placed under natural conditions for 3 months. / kg.

Embodiment 2

[0025] According to the ratio in Table 1, first mix alumina powder and anthracite powder, then add light-burned magnesium powder and mix them together, and then grind them together until the particle size is ≤ 3mm to make additives. Put it into a vacuum tube furnace, control the CO content of the reducing gas to 80~90%, reduce and roast at 800°C for 30 minutes, measure the leaching toxicity of hexavalent chromium after the reaction is 0.064mg / kg, and measure it after 3 months under natural conditions The leaching toxicity of hexavalent chromium is 0.067mg / kg.

Embodiment 3

[0027] According to the ratio in Table 1, first mix alumina powder and anthracite powder, then add light-burned magnesium powder and mix them together, and then grind them together until the particle size is ≤ 3mm to obtain additives. Mix the additives with chromium slag evenly. Put it into a vacuum tube furnace, control the CO content of the reducing gas to 80~90%, reduce and roast at 1000°C for 20 minutes, measure the leaching toxicity of hexavalent chromium after the reaction is 0.011mg / kg, and measure it after 3 months under natural conditions The leaching toxicity of hexavalent chromium is 0.015mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com