Coagulating agent for treatment of leather-making waste water and leather-making waste water treating method

A technology of tannery wastewater and treatment methods, which is applied in animal processing wastewater treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of waste of acid and iron resources, difficulty in dehydration of sludge, and difficulty in post-treatment, etc., and achieve reduction Effect of processing cost, reduction of processing burden, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

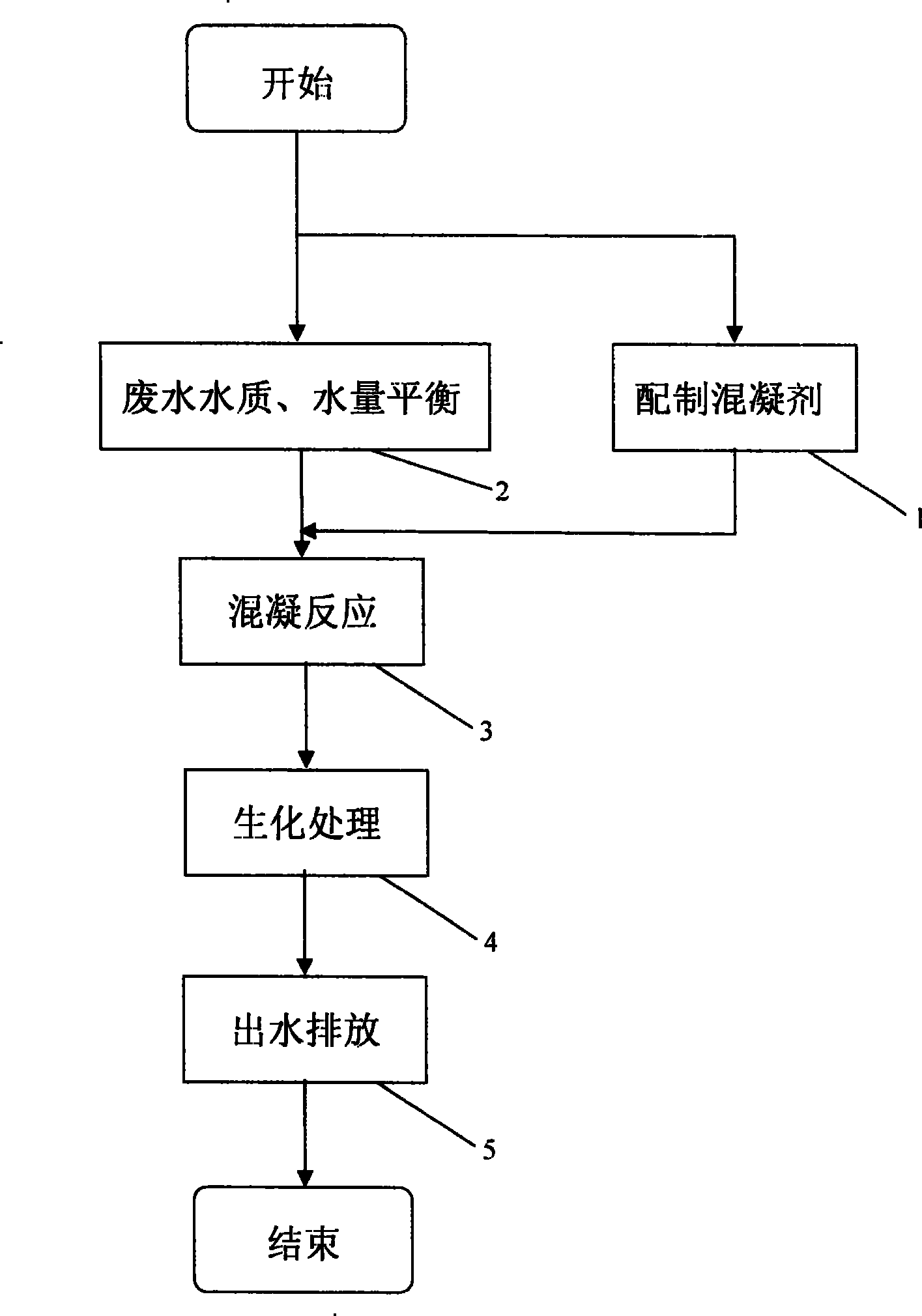

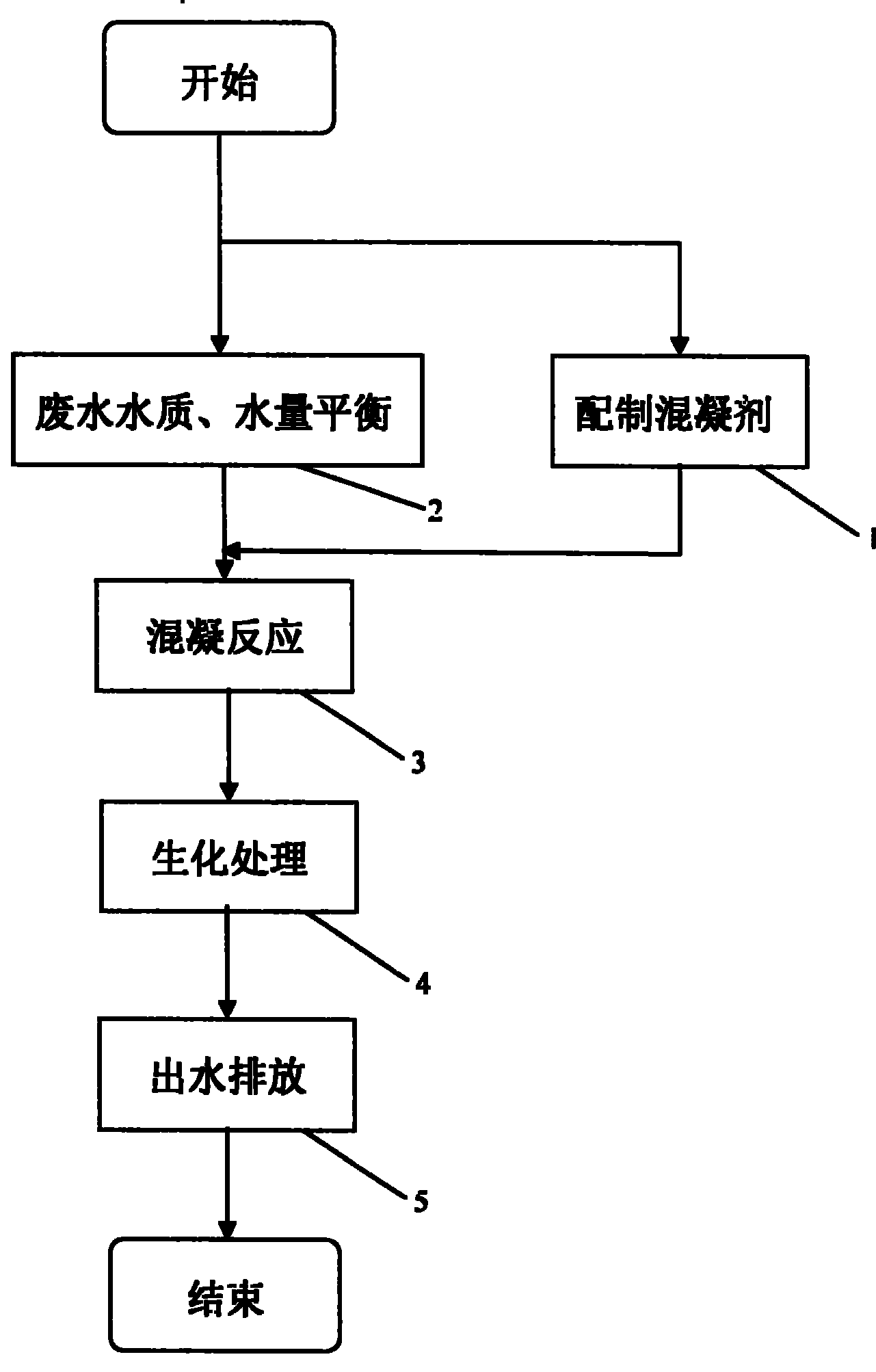

Method used

Image

Examples

Embodiment 1

[0043] Coagulant for tannery wastewater treatment, containing waste pickling liquid, calcium aluminate, additives and catalysts, of which, waste pickling liquid: 90%; calcium aluminate: 8.99%; auxiliary agent: 1%; catalyst: 0.01 %. The auxiliary agent adopts the aluminum silicate catalyst and mainly includes glucose, vitamins, salt and ferric chloride. The components of the pickling waste liquid mainly include ferrous chloride or ferrous sulfate, hydrogen chloride and water, and the mass percentage of each component is 10-20% of ferrous chloride or ferrous sulfate, 3-10% of hydrogen chloride, and the remaining The amount is water. After mixing the pickling waste liquid, calcium aluminate, additives and catalysts according to the above ratio, use steam to heat and stir at the same time to prepare a special coagulant; the steam heating temperature is 95°C-120°C, and the reaction is stirred for about 8 hours .

Embodiment 2

[0045] Coagulant for tannery wastewater treatment, containing waste pickling liquid, calcium aluminate, additives and catalysts, of which, waste pickling liquid: 61.99%; calcium aluminate: 37%; additives: 1%; catalyst: 0.01 %. The auxiliary agent is aluminum silicate. The components of the catalyst mainly include glucose, vitamins, salt and ferric chloride. The components of the pickling waste liquid mainly include ferrous chloride or ferrous sulfate, hydrogen chloride and water, and the mass percentage of each component is 10-20% of ferrous chloride or ferrous sulfate, 3-10% of hydrogen chloride, and the balance for water. After mixing the pickling waste liquid, calcium aluminate, additives and catalysts according to the above ratio, use steam to heat and stir at the same time to prepare a special coagulant; the steam heating temperature is 95°C-120°C, and the reaction is stirred for about 8 hours .

Embodiment 3

[0047] Coagulant for tannery wastewater treatment, containing waste pickling liquid, calcium aluminate, additives and catalysts, of which, waste pickling liquid: 85%; calcium aluminate: 11.97%; additives: 3%; catalyst: 0.03 %. The auxiliary agent is aluminum silicate. The components of the catalyst mainly include glucose, vitamins, salt and ferric chloride. The components of the pickling waste liquid mainly include ferrous chloride or ferrous sulfate, hydrogen chloride and water, and the mass percentage of each component is 10-20% of ferrous chloride or ferrous sulfate, 3-10% of hydrogen chloride, and the balance for water. After mixing the pickling waste liquid, calcium aluminate, additives and catalysts according to the above ratio, use steam to heat and stir at the same time to prepare a special coagulant; the steam heating temperature is 95°C-120°C, and the reaction is stirred for about 8 hours .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com