Method for improving treatment effect of activated carbon filter tank and prolonging service life of activated carbon

A technology of activated carbon filter and treatment effect, applied in the fields of filtration treatment, chemical instruments and methods, separation methods, etc., can solve the problems of low efficiency, little removal effect of activated carbon filter, and high energy consumption, so as to reduce production costs, Solve the effect of frequent carbon change or activated carbon regeneration and improve adsorption index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

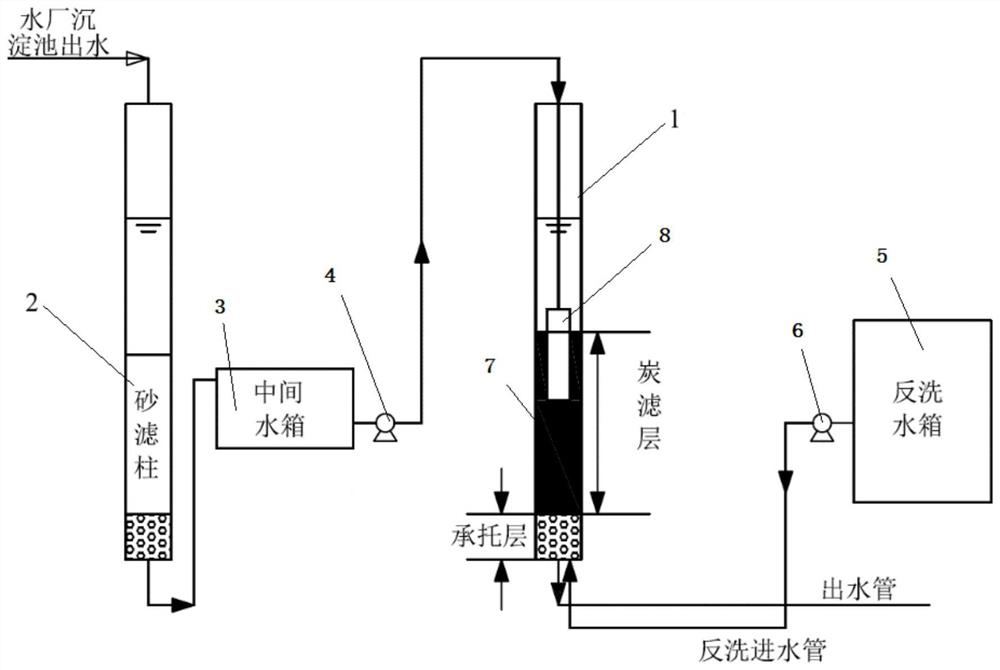

[0064] Pack activated carbon 7 with a carbon age of 4-5 years (such as 4.5 years) in the carbon filter column 1, such as figure 1 , wherein the carbon filter column is a cylinder with a height of 2250mm; a perforated filter plate is provided at the bottom of the carbon filter column, and a 100mm support layer is filled above the filter plate, and activated carbon from the carbon filter of the waterworks is filled above the support layer. The height is 800mm, forming a carbon filter layer, simulating the activated carbon filter to treat tap water; then installing an ultrasonic vibration rod 8 on the top of the carbon filter layer (that is, from the surface of the carbon filter layer to the carbon filter layer 500mm (usually the depth of the ultrasonic vibration rod embedded in the carbon layer) 40-60% or more) is equipped with an ultrasonic vibration rod with a diameter of DN100mm in the middle); the ultrasonic power is 0-800W (adjustable), and the ultrasonic frequency is 36.4KH...

Embodiment 1A

[0124] Activated carbon with a carbon age of 5 years is loaded and filtered according to the method of Example 1.

[0125] 1. Monitor the quality of influent and effluent water before and after activated carbon filtration

[0126] Measured according to the monitoring method of Example 1, the results are shown in Table 5. Table 5 shows the monitoring data of influent and effluent water quality from the 9th to 17th day of normal operation.

[0127] Table 5 Example 1A water quality monitoring results before and after activated carbon filtration

[0128]

[0129]

[0130] 2. Calculate the CS coefficient, the first individual ratio, and the second individual ratio

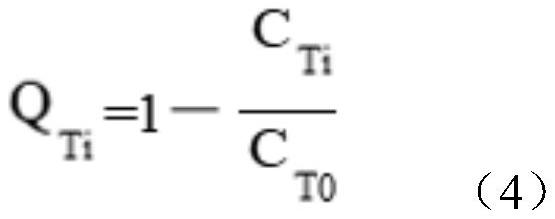

[0131] 2-1) According to the measured COD of the effluent Mn Value, according to the formula (4) to calculate the first single ratio that is COD Mn Ratio, the measurement results are shown in Table 6;

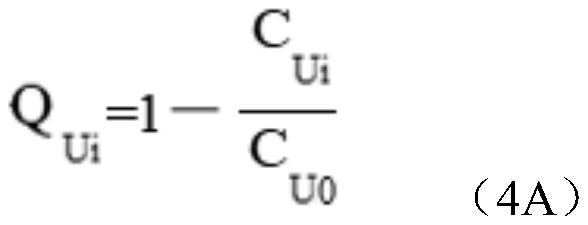

[0132] 2-2) According to the chloroform concentration value of the effluent measured, calculate the second ...

Embodiment 1B

[0143] Activated carbon with a carbon age of 5 years is loaded and filtered according to the method of Example 1.

[0144] 1. Monitor the quality of influent and effluent water before and after activated carbon filtration

[0145] Measured according to the monitoring method of Example 1, the results are shown in Table 7. Table 7 shows the monitoring data of influent and effluent water quality on the 13th-22nd day of normal operation.

[0146] Table 7 Water quality monitoring results before and after activated carbon filtration of embodiment 1B

[0147]

[0148] 2. Calculate the CS coefficient, the first individual ratio, and the second individual ratio

[0149] 2-1) According to the measured COD of the effluent Mn Value, according to the formula (4) to calculate the first single ratio that is COD Mn Ratio, the measurement results are shown in Table 8;

[0150] 2-2) According to the chloroform concentration value of the effluent measured, calculate the second single ite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com