Cold rolling tempering lubricant waste water treatment device and treatment method thereof

A wastewater treatment and leveling liquid technology, which is applied in metallurgical wastewater treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve serious pollution, difficult treatment of wastewater chemical stability, relatively large water quality changes, etc. problems, to achieve the effect of less investment, good effluent water quality, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

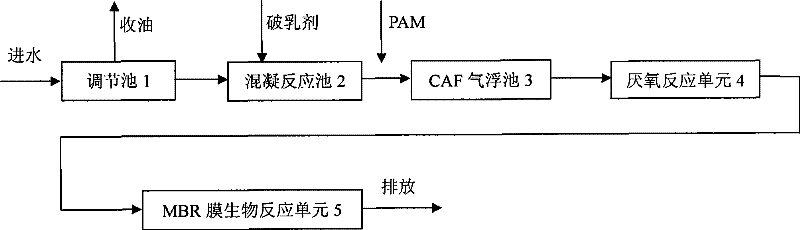

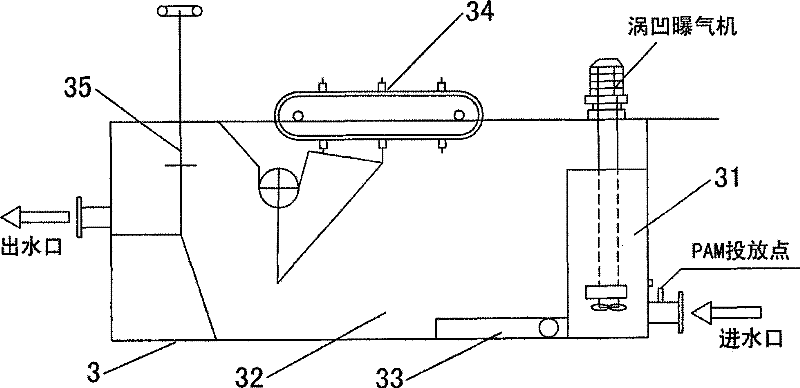

[0043] Such as figure 1 Shown, a kind of cold-rolled leveling fluid waste water treatment device, it comprises: adjusting tank 1, coagulation reaction tank 2, CAF air flotation tank 3, anaerobic treatment unit 4 and MBR membrane biological reaction unit 5; Its cold rolling leveling liquid wastewater The processing method includes the following steps:

[0044] (1) Transport the leveling liquid wastewater to the regulating tank for oil recovery treatment, which is used to reduce the COD concentration and oil content in the leveling liquid wastewater;

[0045] (2) transporting the leveling liquid waste water treated in step (1) to the coagulation reaction tank, carrying out coagulation reaction in the coagulation reaction tank, absorbing the suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com