Magnesium-iron-based organic adhesive for iron-making pellet

A technology of organic binder and pellets, applied in the field of composite binder, can solve the problems of sintered ore output and quality indicators, improve compressive strength and total iron grade, improve metallurgical properties, and improve green pellets. Effects of strength and burst temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

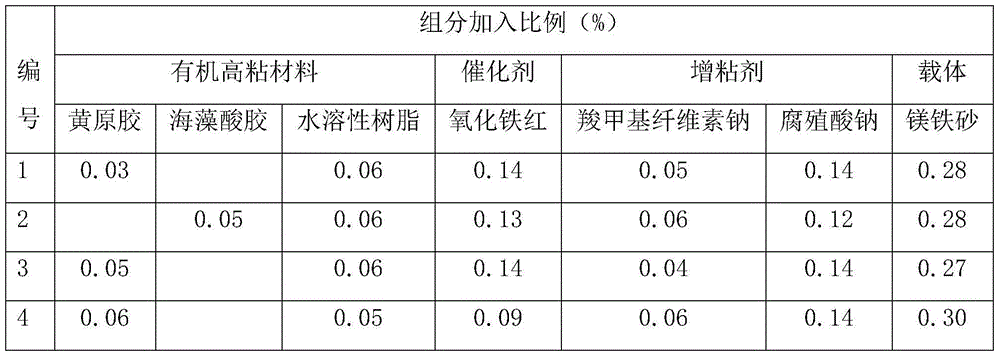

[0017] The magnesium-iron-based organic binder for ironmaking pellets has the following components by weight percentage: 10-20% of organic high-viscosity material; 20-30% of catalyst; 10-20% of tackifier; and 50-70% of carrier. The organic high-viscosity material is one or a mixture of xanthan gum, alginate gum and water-soluble resin. The catalyst is iron oxide red. Described tackifier is sodium carboxymethyl cellulose and sodium humate. The carrier is magnesia sand. See Table 1 for example organic binder components.

[0018] Table 1: Example Components of Pellet Magnesium-Fe-Based Organic Binders

[0019]

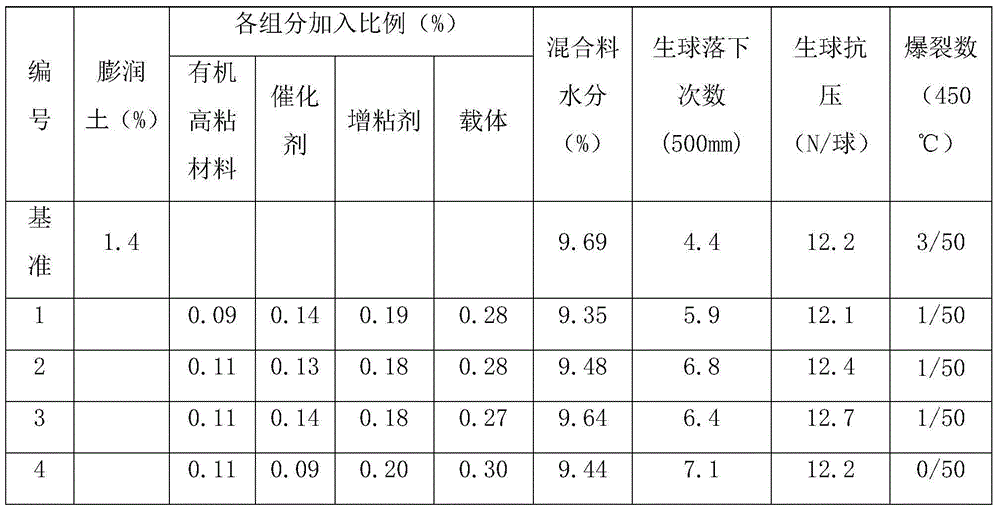

[0020] According to the formula, it is mixed according to the proportion and then co-milled, and the mass percentage of the particle size -0.074mm particle size is ≥ 70%. Then, 0.7% by weight of the above-mentioned magnesium-iron-based pellet organic binder is added to the iron ore concentrate powder. See Table 2 for the comparison table of the raw pellet indexes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com