A device for adding organic binder for sintering pellets

A technology of organic adhesives and adding equipment, applied in the direction of mixers with rotating containers, mixers, mixer accessories, etc., can solve the problems of poor viscosity, powdering strength, pellet cracking, etc., and achieve excellent Physicochemical effect, increase iron content, promote oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]Embodiment 1: An organic binder for sintering pellets, including sodium carboxymethylcellulose, Palido, tackifier and additives, the sodium carboxymethylcellulose is 50 parts, Palido 1 part, the additive is KMnO 4 and K 2 Cr 2 o 7 Prepared by mixing, additives include 3 parts KMnO 4 and 2 copies of K 2 Cr 2 o 7 Prepared by mixing;

[0026] Described tackifier is cationic guar gum, and cationic guar gum is a kind of natural copolymer that extracts from leguminous plant, has cationic surfactant and macromolecular resin characteristic, and its outward appearance is light yellow powder, odorless or Slightly fragrant, the thickener includes the following raw materials by weight: 10 parts of polysaccharide (high molecular polymer formed by D-mannose and D-galactose at a ratio of 2:1), 8 parts of water, 6 parts of protein, Prepared by mixing 1 part of ash powder and 0.7 part of cellulose;

[0027] 25 parts of dolomite are also added in the binder;

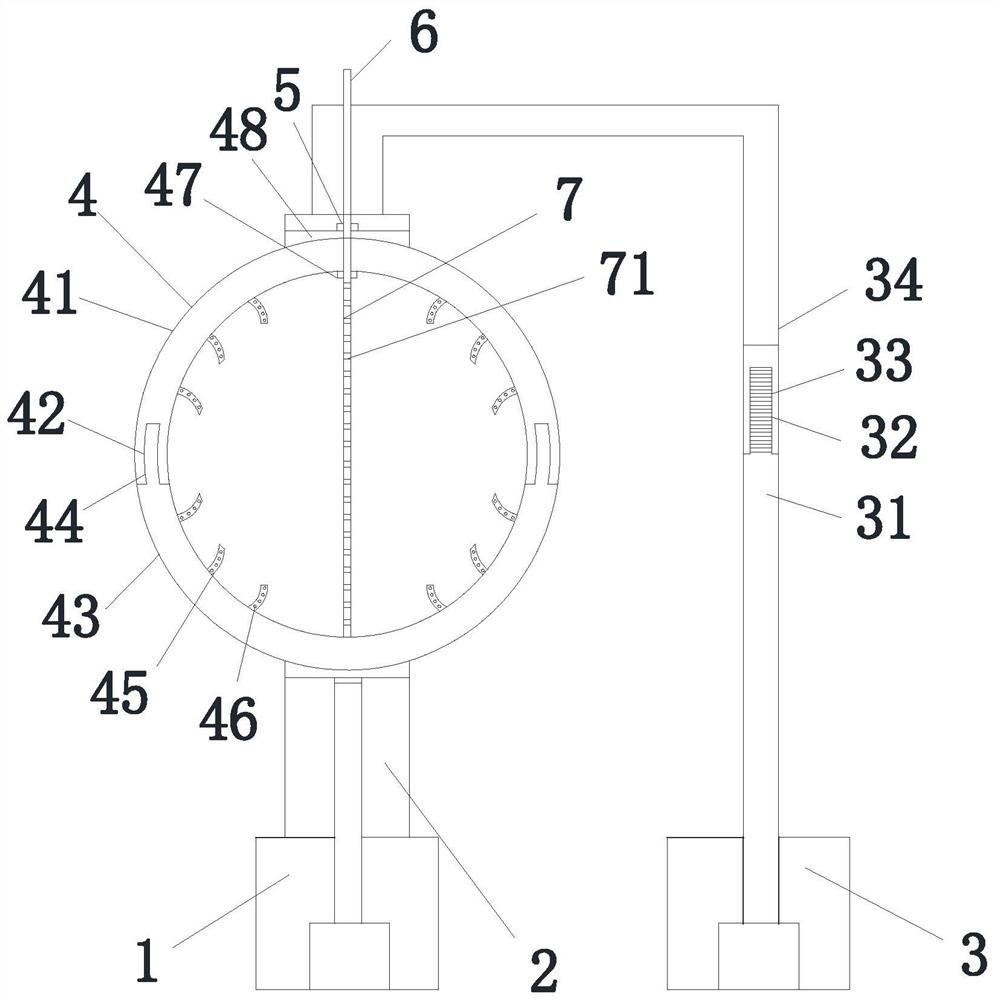

[0028] A device fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com