Sintering ore-proportioning method for different kinds of iron material mostly comprising hematite concentrate

A hematite concentrate and multi-variety technology, which is applied in the field of agglomeration of sintered ore as raw material for ironmaking, can solve the problem of mineral composition regardless of the influence of FeO sintering process, regardless of the type of iron ore, the complementarity of sintering characteristics, and the strength of sintered ore To improve the strength, improve the sintering performance and reduce the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

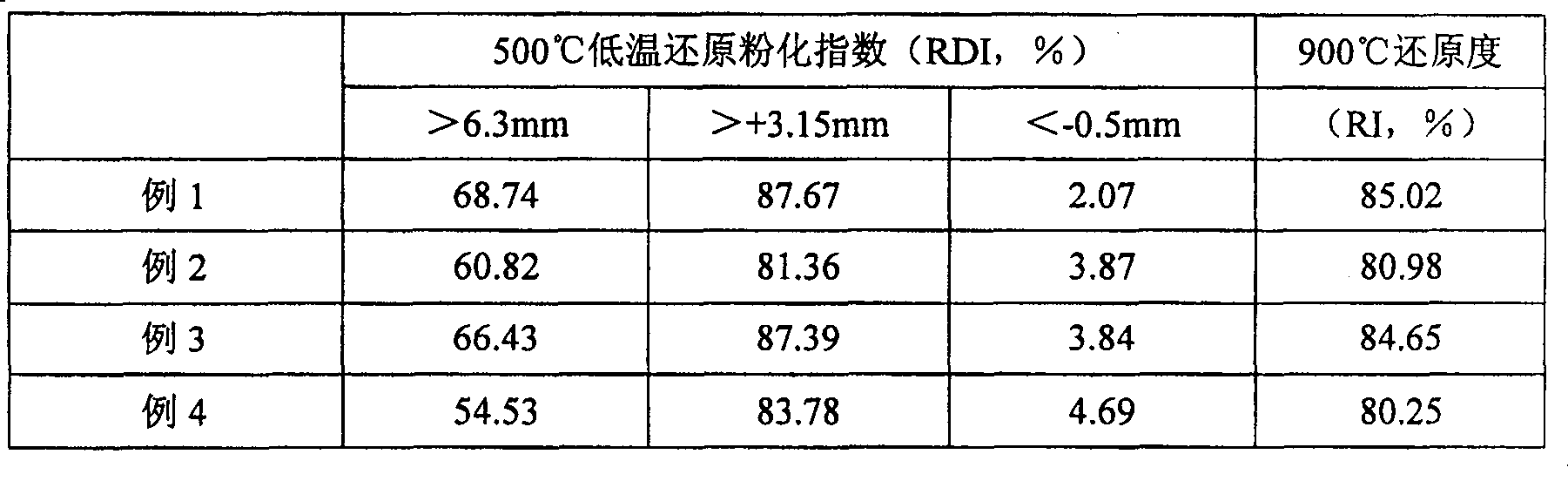

Examples

Embodiment Construction

[0014] The present invention will be further described by the following examples.

[0015] First determine the other iron materials used. In the embodiment of the present invention, A magnetite concentrate (a type of A magnetite), B magnetite concentrate (a type of B magnetite) and iron oxide scale are used, and then the hematite concentrate Check the chemical composition of other iron materials. The measured chemical composition and burning loss of each iron material are shown in Table 1. In order to better illustrate the problem, the embodiment of the present invention selects hematite concentrate with fine particle size and low FeO content as an example.

[0016] Table 1 Chemical composition of iron material (%)

[0017] project TFe FeO SiO 2 CaO MgO Burn Hematite concentrate 64.70 1.35 6.15 0.15 0.30 2.01 A magnetite concentrate 68.26 21.01 3.50 0.15 0.30 -1.62 B magnetite concentrate 66.17 28.65 7.00 0.30 0.35 -2.32 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com