Leather manufacture and production process thereof

A production process and leather technology, which is applied in the field of leather production and its production process, can solve the problems of non-environmental protection and low operation efficiency of leather processing, and achieve the effect of solving low operation efficiency, ensuring safe operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

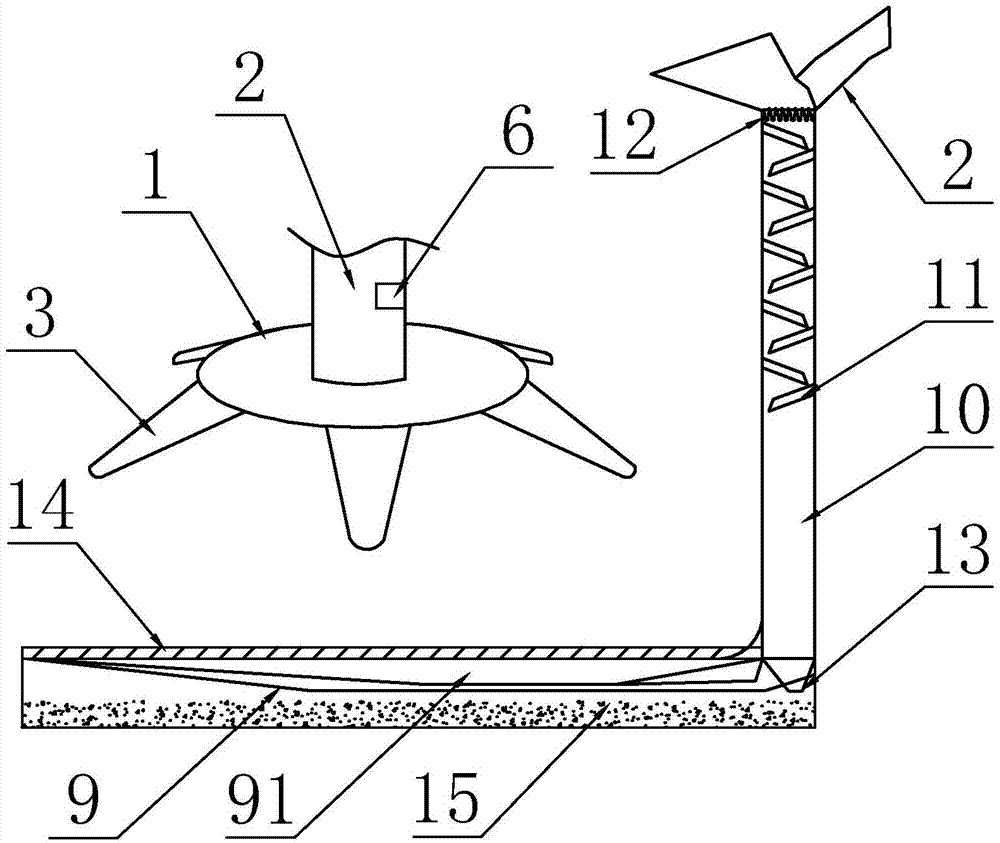

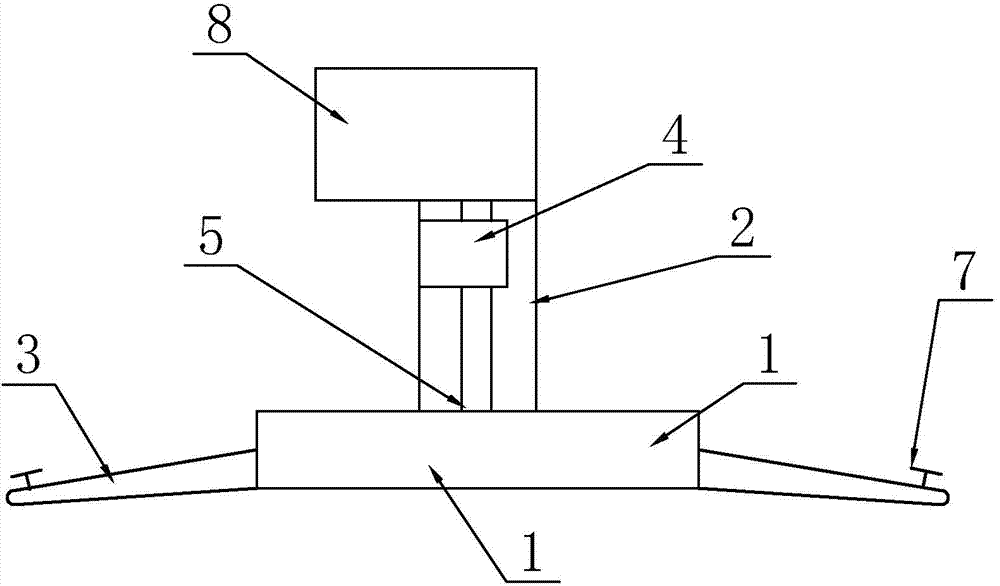

[0022] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0023] like figure 1 combine figure 2 Shown, a kind of leather production and its production technology, comprise the steps:

[0024] 1) Lay the leather blank into the water squeezer for physical extrusion and vacuum adsorption, and remove the moisture in the leather blank as much as possible;

[0025] 2) Preliminary air-drying, the leather is suspended in the air, and the air-drying step is that the leather is suspended in the air while moving at a constant speed. The moving route is preferably circular, and the time is selected within the range of 30min-45min;

[0026] 3) Lay flat and fix on the vertical stretching board and send it to the oven for hot air baking. The baking time is 10min-15min. The vertical stretching board is arranged vertically and parallel, and distributed in a circle. Simultaneously with the removal or fixation of leather that has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com