Automatic discharging device

A blanking device and automatic technology, applied in the direction of transportation and packaging, slideway, etc., can solve the problems of inconvenient retrieving and affecting the efficiency of insertion and insertion, and achieve the effect of avoiding chaos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

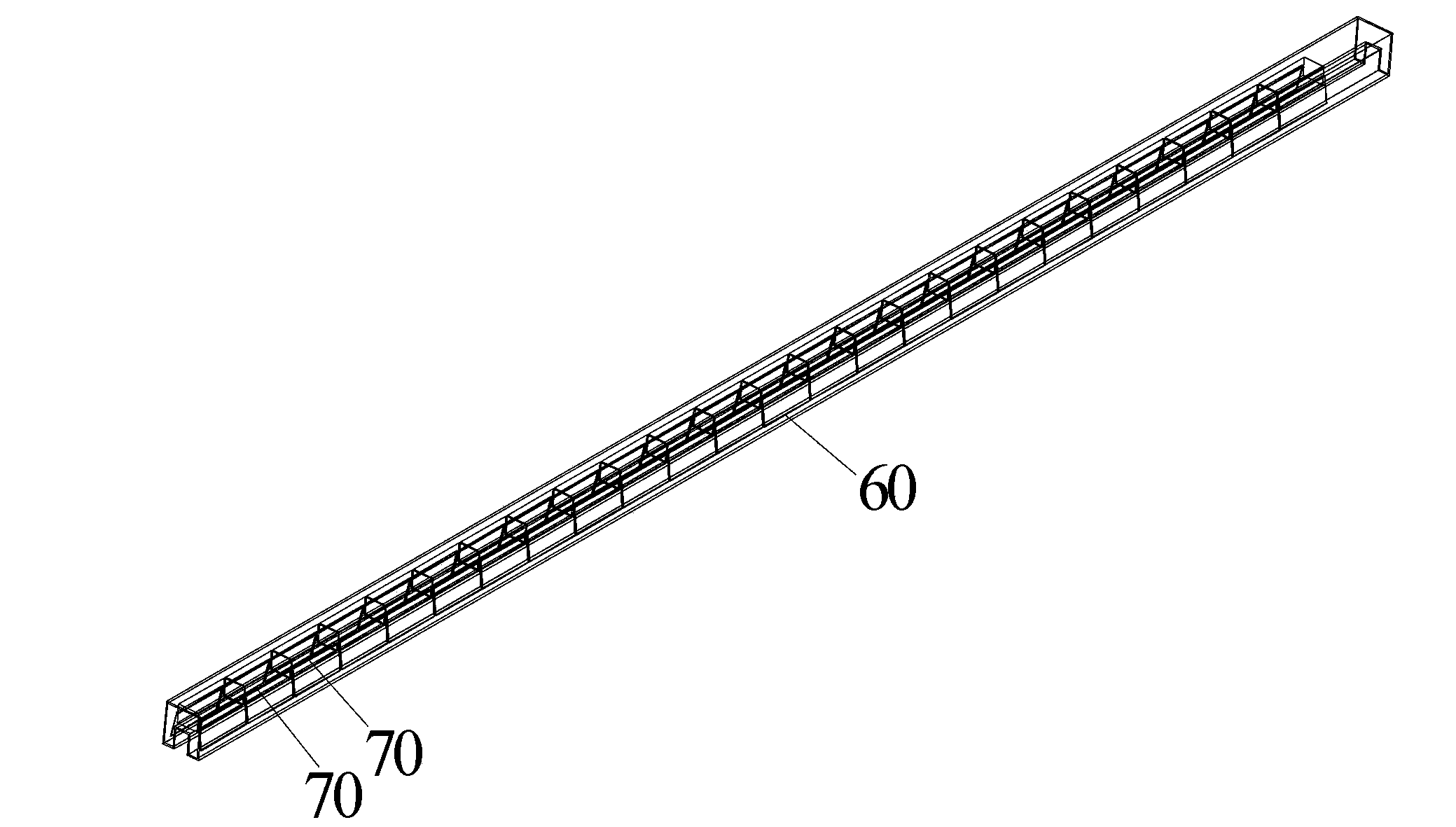

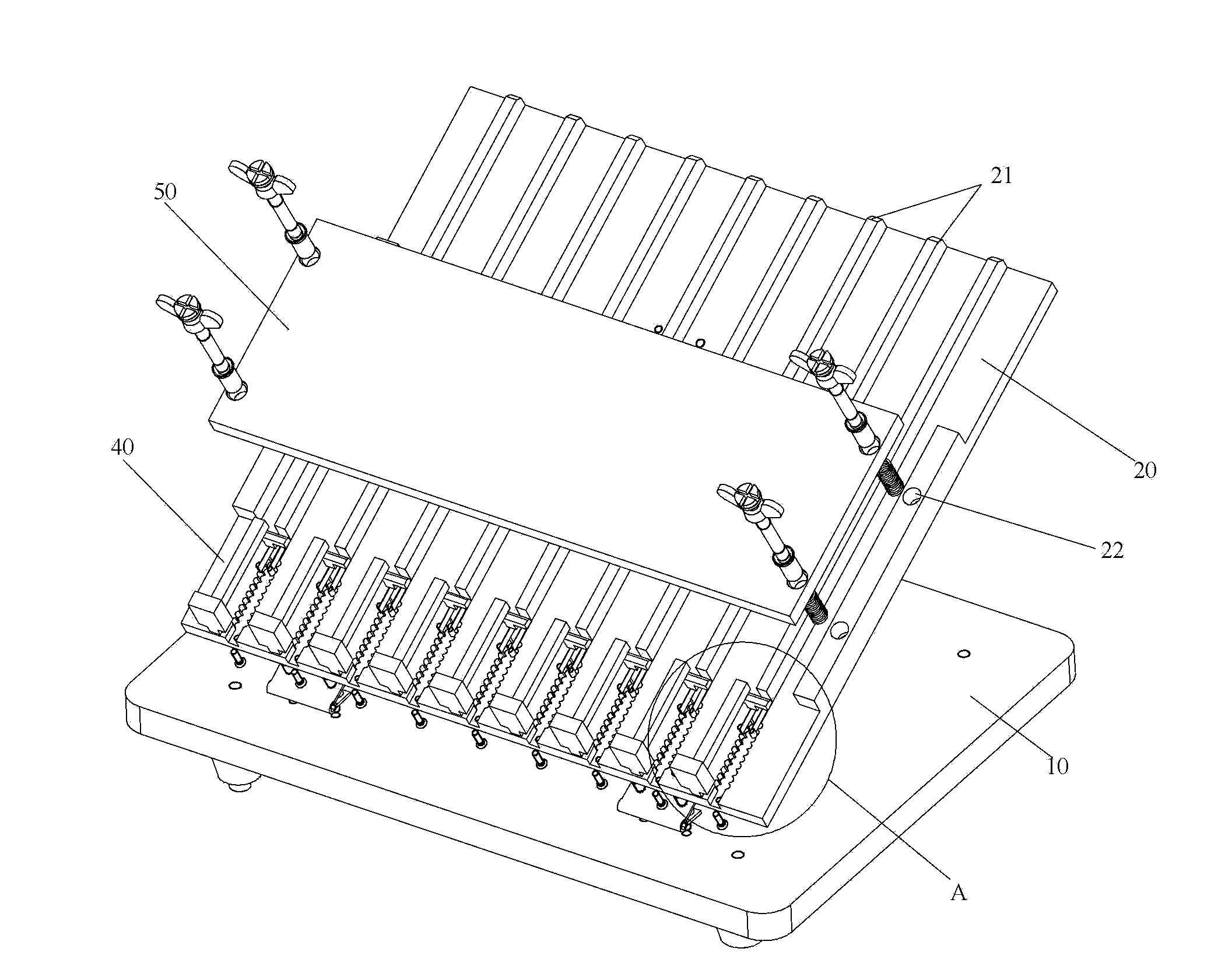

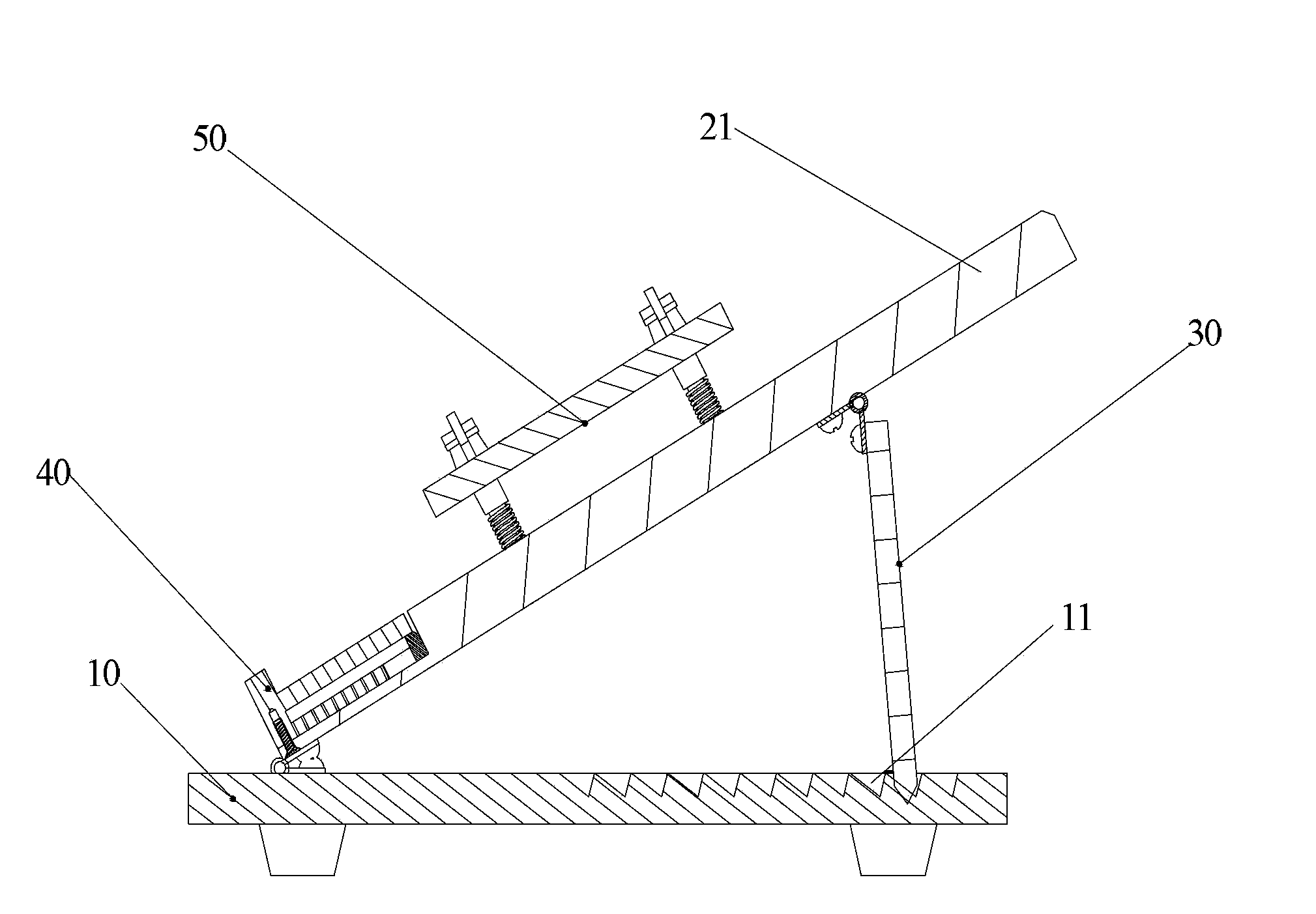

[0029] see Figure 2 to Figure 7 , according to a kind of automatic blanking device of the present invention, comprise blanking board 20, vertically or obliquely be arranged on the horizontal plane; Rail 21 is arranged on blanking board 20, material tube 60 is placed on track 21, and material tube The electronic components 70 in the 60 can slide down along the track 21 ; the main block 43 is arranged at the lower end of the track 21 , and is used to block the electronic components 70 on the track 21 in sequence. By setting the track, the material tube is fixed on the track 21, without the need for electronic components to be poured from the inside of the material tube into the material box, so that the current problems of mutual extrusion of electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com