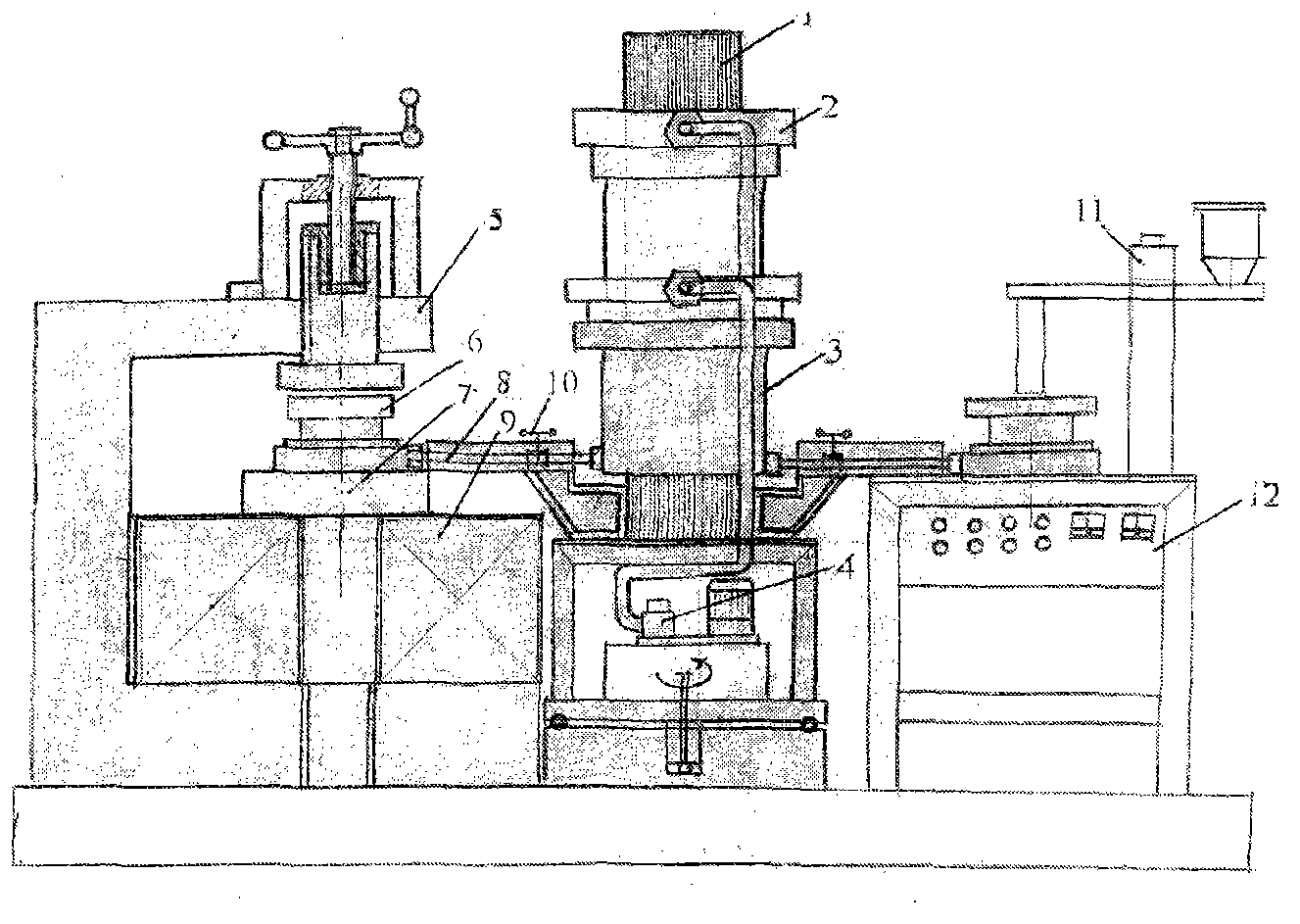

Technology and device for forming dry bag quick isostatic pressing in oriented magnetic fields

A technology of oriented magnetic field and forming technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of large consumption of soft mold bags, reduced green compact density, uneven density, etc., to save resources and man-hours The effect of cost, product qualification rate improvement, and uniform distribution of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare a tile-shaped NdFeB sintered magnet, the properties:

[0027] The magnetic energy product is (BH)max / 40(MG.Oe); the alloy density is 7.6g / cm 3 ;The size of the tile-shaped product is: (length) 40mm×(width) 20mm×(thickness) 8mm, and the inner arc surface is R50mm. Polishing after sintering is required.

[0028] The relevant soft mold design and preparation methods are as follows:

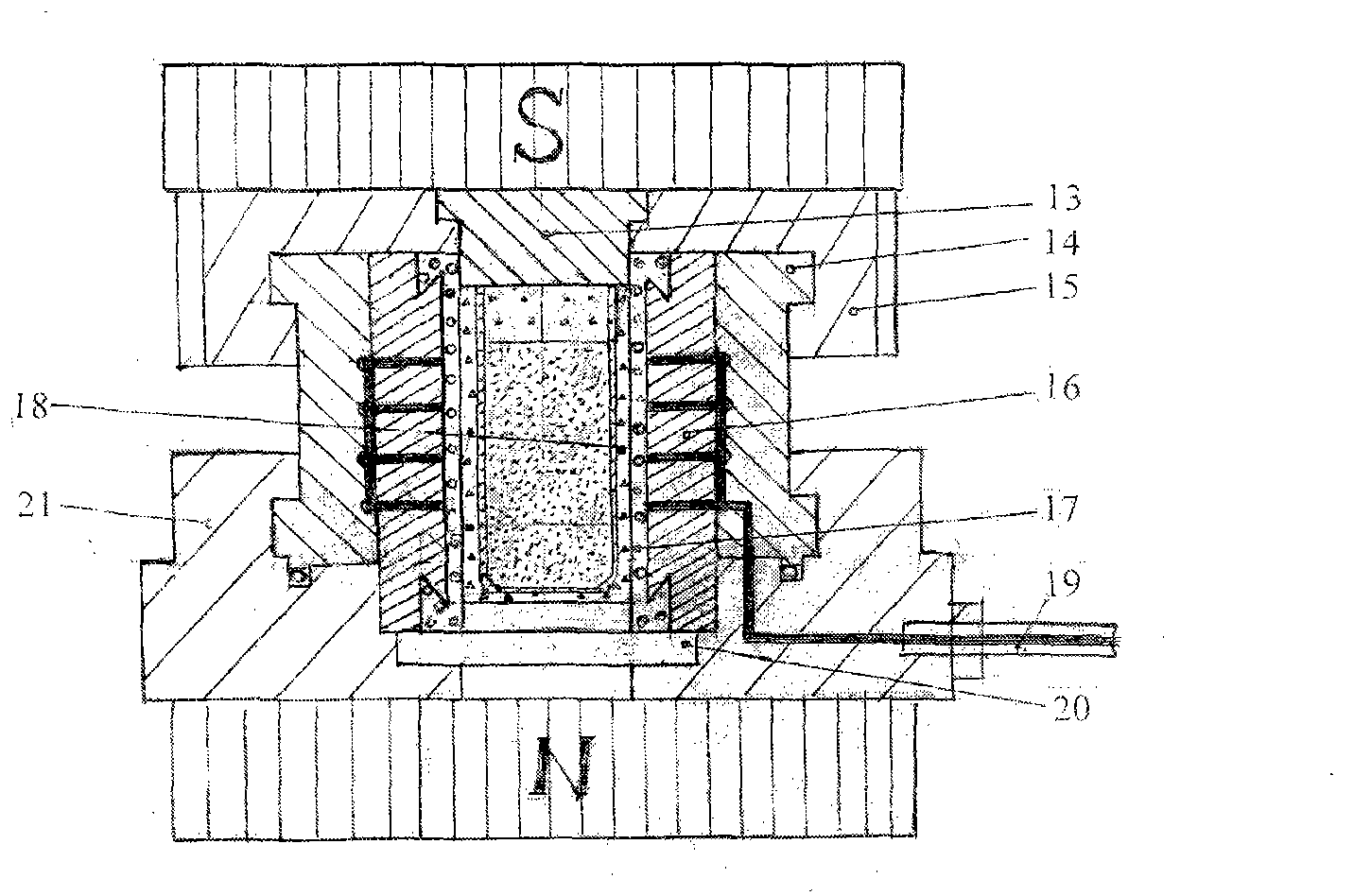

[0029] 1. Dry bag type rapid cold isostatic pressing mold design

[0030] Mold structure and attached figure 2 It is exactly the same, but the size of each part of the mold should start from the compact size design and related calculations.

[0031] 1.1. Compact design

[0032] 1.1.1. Determination of the size of the sintered body

[0033] Final size of sintered body: length L 1 =40mm, width b 1 =20mm, thickness H 1 =8mm, inner arc surface R 内1 =50mm, outer arc surface R 外1 = 58mm.

[0034] 1.1.2. Compact size calculation

[0035] K- compact size magnification factor 1.16...

Embodiment 2

[0080] Preparation of medium-sized tile-shaped NdFeB sintered magnets, various properties:

[0081] The magnetic energy product is (BH)max / 40(MG.Oe); the alloy density is 7.6g / cm 3 ;The size of the medium-sized tile-shaped product is: (length) 80mm×(width) 40mm×(thickness) 16mm, and the inner arc surface is R100mm. Polishing after sintering is required.

[0082] The relevant soft mold design and preparation methods are as follows:

[0083] 2.1 Dry bag type rapid cold isostatic pressing die design

[0084] Mold structure and attached figure 2 It is exactly the same, but the size of each part of the mold should start from the compact size design and related calculations.

[0085] 2.1. Compact design

[0086] 2.1.1. Determination of the size of the sintered body

[0087] Final size of sintered body: length L 1 =80mm, width b 1 =40mm, thickness H 1 =16mm, inner arc surface R 内1 =100mm, outer arc surface R 外1 =116mm.

[0088] 2.1.2. Compact size calculation

[0089] K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com