A blast furnace coal injection system and its control method

A technology of blast furnace coal injection and coal injection tank, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of blast furnace stability and unfavorable movement, outlet pressure fluctuations, and the complexity of gas-solid two-phase flow, etc. The effect of tank fluctuation time and improvement of injection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

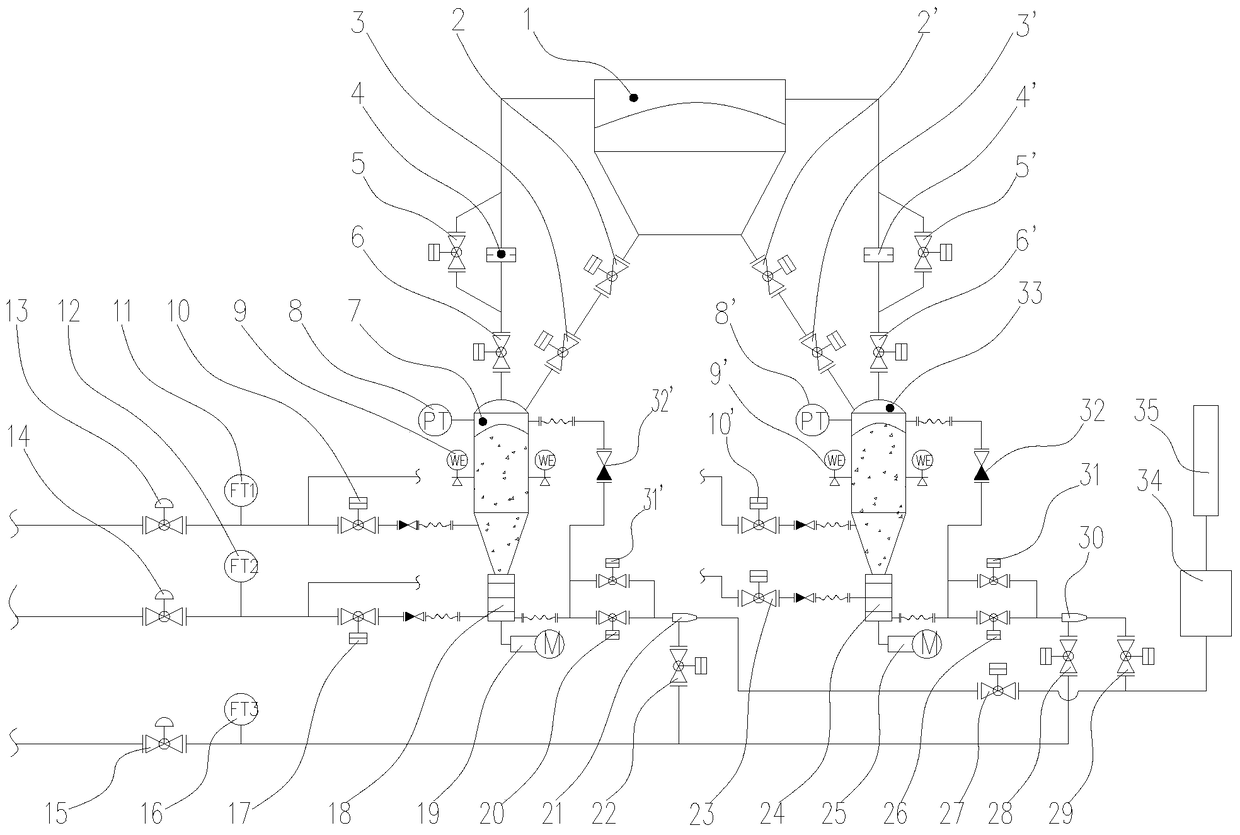

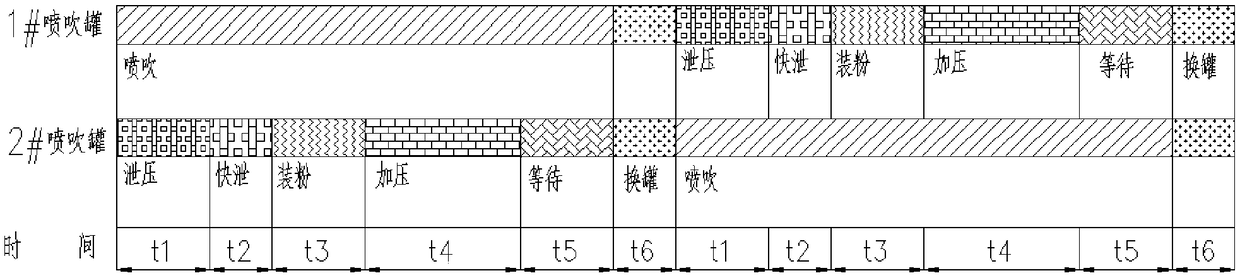

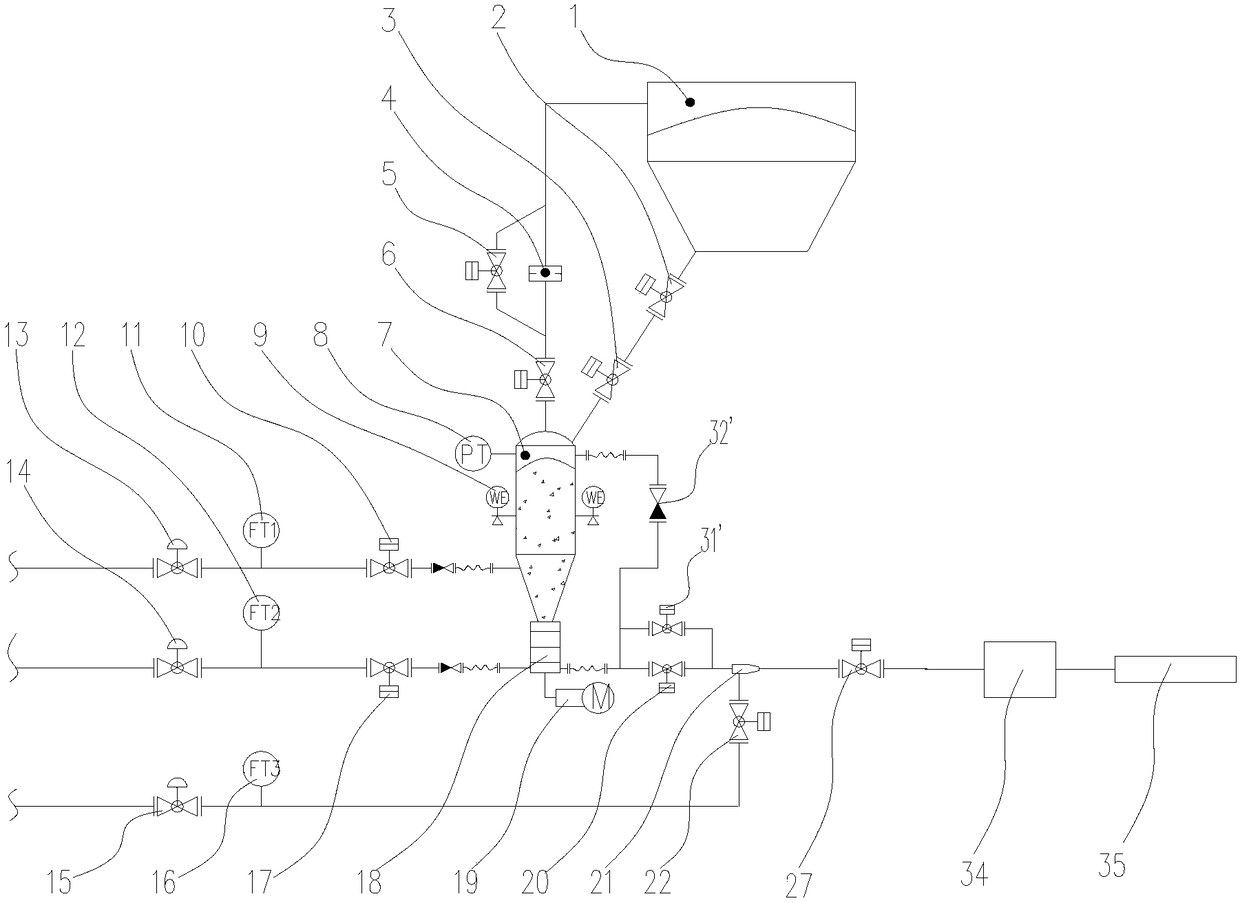

[0033] Such as figure 1 As shown, a blast furnace coal injection system includes pulverized coal bunker 1, 1# injection tank 7, 2# injection tank 33, 1# air replenisher 21, 2# air replenisher 30, distributor through pipelines 34 and spray gun 35, the bottom of described 1# injection tank 7 and 2# injection tank 33 are respectively provided with 1# quantitative feeder 18 and 2# quantitative feeder 24, 1# quantitative feeder 18 and 2 # Quantitative feeder 24 outlets are respectively connected to the first pulverized coal main pipe and the second pulverized coal main pipe, and the first pulverized coal main pipe is provided with 1# injection tank coal outlet valve 20, 1# air supply device 21 and 1# spray tank in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com