Dual fluidized bed ¿Ccombustion coupling equipment for preparing synthesis gas in high concentration from solid fuel

A solid fuel, double fluidized bed technology, applied in the direction of granular/powdered fuel gasification, combined combustion mitigation, etc., can solve the problems of equipment investment, high equipment operation and maintenance costs, single fluidized bed equipment, etc., and achieve a high degree of realization The effect of integration and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

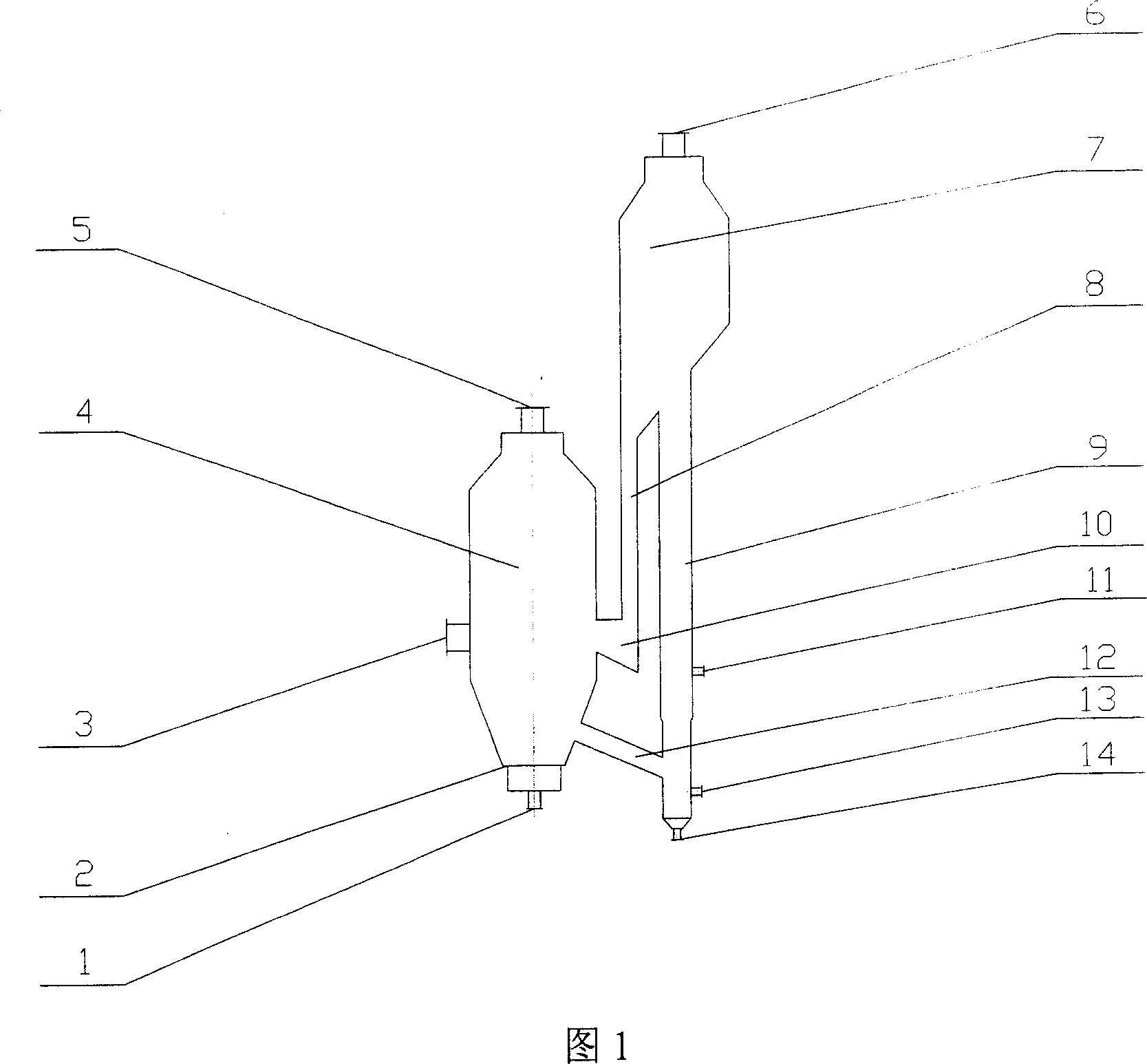

[0017] The fluidized bed is divided into a main fluidized bed 4 and an auxiliary fluidized bed. The straight pipe 9 is connected with the top of the straight pipe 9 to form an auxiliary fluidized bed. The top of the enlarged section 7 is the flue gas outlet 6, and the bottom of the straight pipe 9 It is the ash outlet 14, the lower part of the straight pipe 9 has a primary air inlet 13 and a secondary air inlet 11, and the lower part of the straight pipe 9 communicates with the lower part of the mainstream bed 4 through the circulating inclined pipe 12, and the expansion section 7 passes through the standpipe 8 and The L-shaped valve 10 communicates with the middle part of the main fluidized bed 4, the top of the main fluidized bed 4 is a synthesis gas outlet 5, the bottom of the main fluidized bed 4 has a water vapor inlet 1 and a gas distributor 2, and in the middle of the main fluidized bed 4 there is Fuel inlet 3.

[0018] The solid fuel is transported into the main bed 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com