Method for achieving online blending of multi-grade hydraulic oil through intelligent injection control

A hydraulic oil and intelligent technology, applied in chemical instruments and methods, mixers, chemical/physical processes, etc., can solve the problems of large dosage of additives, high labor intensity, poor preparation accuracy, etc., and achieve high injection accuracy , easy to operate, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention is a method for realizing on-line blending of multiple grades of hydraulic oil through intelligent injection control. The invention uses a set of intelligent injection control device.

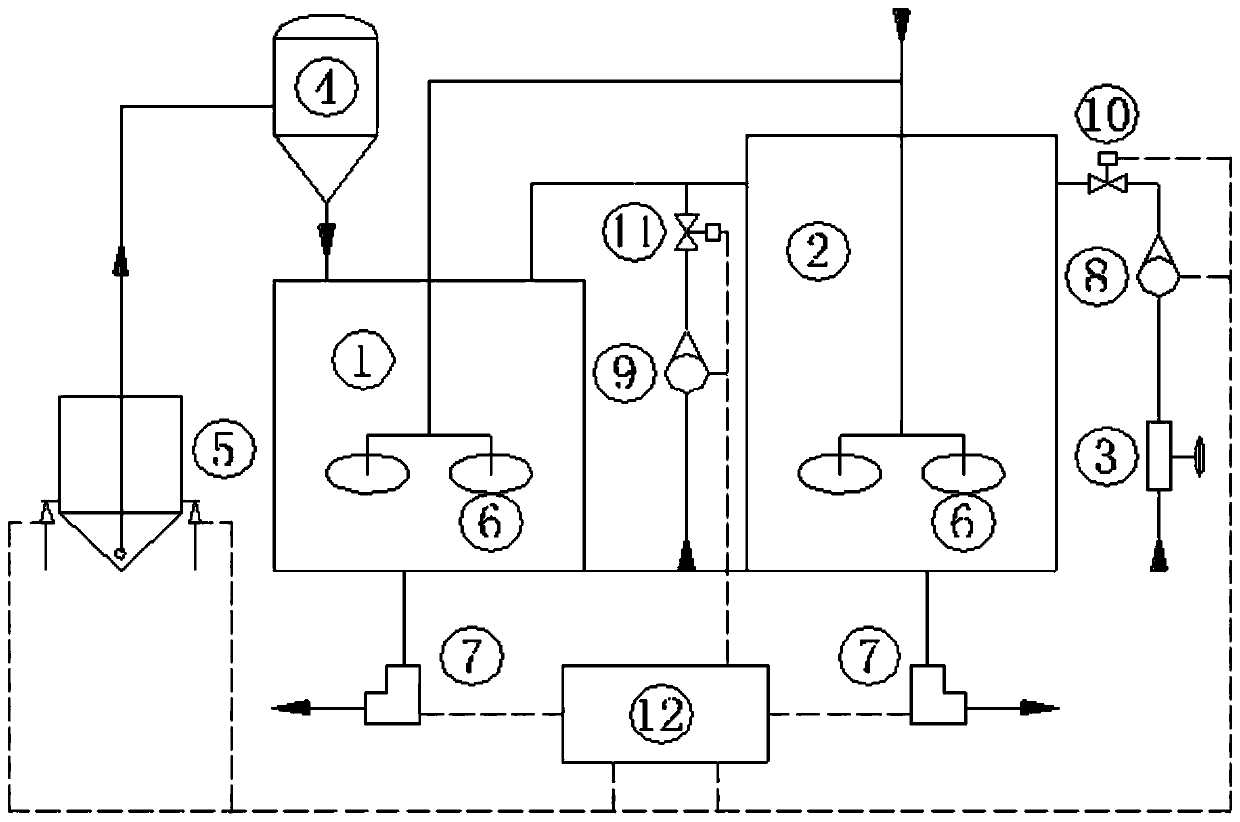

[0022] combine figure 1 , the intelligent injection control device includes a solid agent preparation tank (1), a liquid agent preparation tank (2), a liquid agent unloading pump (3), a solid agent hoist (4), a solid agent metering tank (5), Pulse wind agitator (6), dosing pump (7), liquid flow meter (8), dilution mother liquor flow meter (9), liquid solenoid valve (10), dilution solenoid valve (11) and control cabinet (12).

[0023] The control cabinet of the present invention can store the types and preparation ratios of additives required for hydraulic oil with different formulas. The operator only needs to select the corresponding formula on the setting interface, and the control cabinet can automatically control and start the dosing pump of the corresponding preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com