Automatic tray unloader suitable for small-volume bottles

An automatic unloading, small-capacity technology, applied in the directions of packaging bottles, conveyors, conveyor objects, etc., can solve the problems of low efficiency of manual unloading and high environmental pollution rate, reducing the number of operators, high degree of integration, and structure. Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

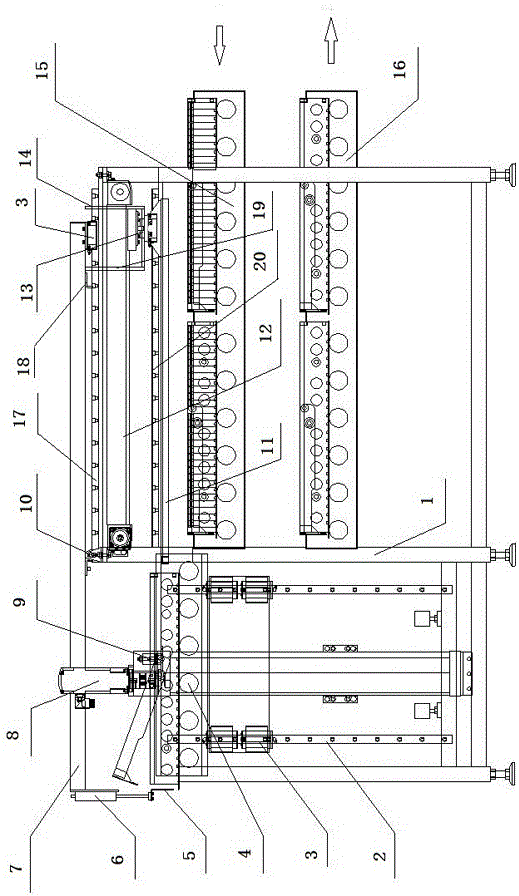

[0021] Example 1, refer to figure 1 , an automatic unloader for small volume bottles:

[0022] The automatic unloading machine includes a rack 1, on which a bottle holding mechanism, a bottle pushing mechanism and an unloading station bracket 4 are installed;

[0023] A lifting mechanism is connected below the unloading station bracket 4; a stopper 9 is provided on the frame 1 above the unloading station bracket 4;

[0024] The bottle-supporting mechanism includes a bottle-supporting power mechanism 6, a bottle-supporting slide rail 17, and a bottle-supporting plate 5 connected with the bottle-supporting power mechanism 6. The bottle-supporting power mechanism 6 is installed on the bottle-supporting connecting plate 7; 7 is connected to the bottle holding slide rail 17 through the slider 3;

[0025] The bottle pushing mechanism includes a bottle pushing power mechanism 12, a bottle pushing slide rail 20, a push rod 11 and a dial. The push rod 11 is connected to the bottle pu...

Embodiment 2

[0027] Example 2, in the automatic unloading machine suitable for small volume bottles described in Example 1: a support roller 10 supporting the bottle holding connecting plate 7 is installed on the frame 1 below the bottle holding connecting plate 7 .

Embodiment 3

[0028] Embodiment 3, in the automatic unloading machine for small-volume bottles described in Embodiment 1 or 2: the bottle holding power mechanism 6 and the bottle pushing power mechanism 12 are selected from air cylinders or electric cylinders.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com