High-precision plunger type trace sampling pump

A micro-sampling pump and plunger-type technology, applied in the direction of pumps, pump control, liquid variable capacity machinery, etc., can solve the problems of sample injection movement, high price, poor precision, etc. Smooth, structurally simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

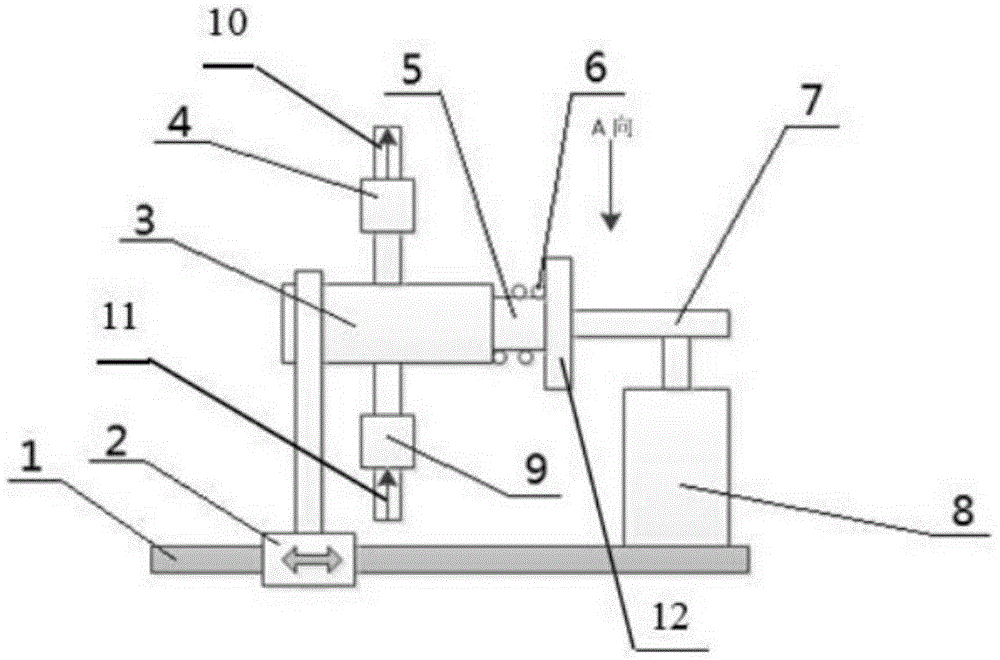

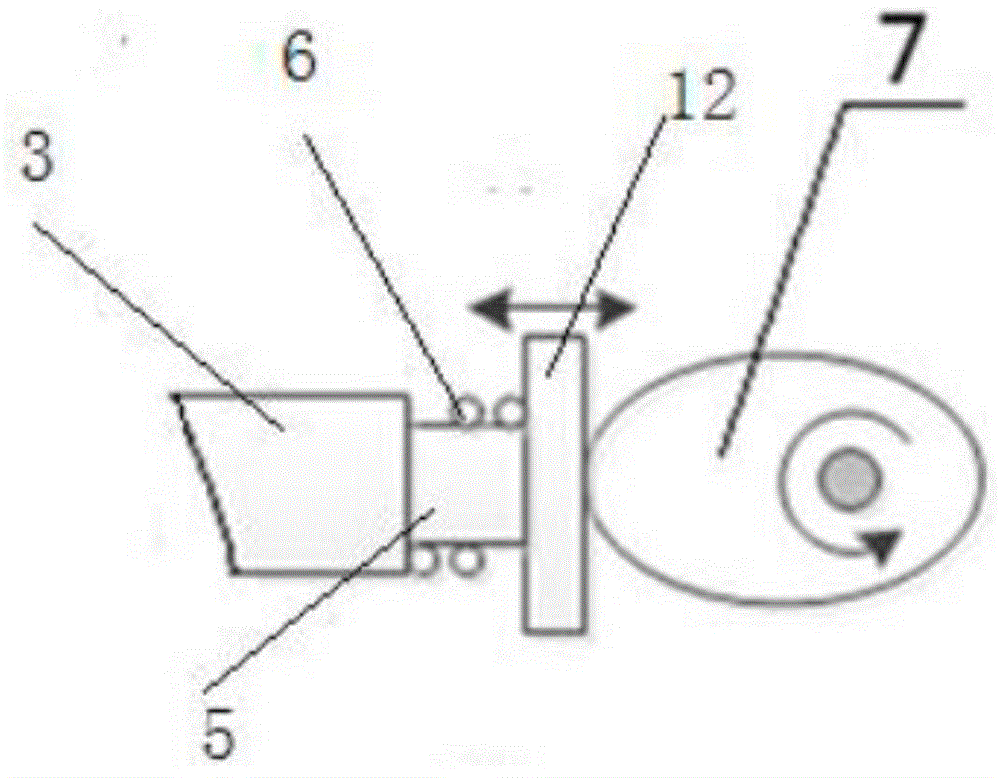

[0022] combined with figure 1 with 2 As shown, a high-precision plunger type micro-sampling pump includes: guide rails, sliding brackets, plunger pumps, liquid inlet conduits, liquid outlet conduits, liquid outlet one-way valves, liquid inlet one-way valves, springs, Cams and motors.

[0023] Described guide rail is arranged horizontally, and links to each other with the bottom end of sliding bracket, so that sliding bracket realizes moving left and right on guide rail; (not marked in the figure) are respectively provided with a liquid inlet check valve and a liquid outlet check valve, one end of the plunger of the plunger pump is embedded in the plunger pump, and the other end is provided with a clutch plate; the spring is coaxially sleeved on the plunger Above, the two ends of the spring are respectively in contact with the clutch plate and the plunger pump; the motor is fixedly placed, and a cam is fixed on the drive shaft.

[0024] Select the motor model as UTmotor35HB3...

Embodiment 2

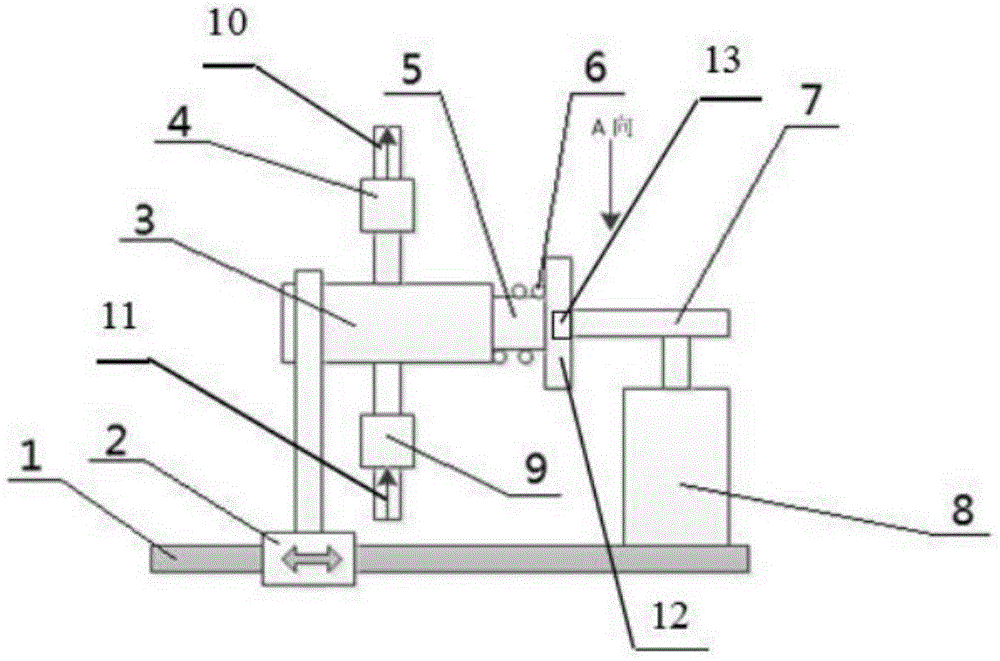

[0028] combined with image 3 with 4 As shown, a high-precision plunger type micro-sampling pump, the structure is basically the same as that of Embodiment 1, and a load cell is embedded in the clutch plate, preferably embedded in the center of the outer end surface of the clutch plate and the cam. A load cell, the load cell is connected to a controller, and the controller is connected to a motor, wherein:

[0029] The load cell is used to collect the pressure signal generated by the contact between the cam and the clutch plate when the motor drives the cam to rotate, and transmit the collected pressure signal to the controller;

[0030] The controller is used to receive the pressure signal sent by the load cell, and compare this pressure signal with the set pressure signal, when the two pressure signals are equal or the pressure signal sent by the load cell reaches the set pressure When the signal is 90-95%, send a control signal to the motor to make the motor reverse rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com