Automatic sampler of liquid chromatograph, and automatic correction method of sampling hole of automatic sampler

A technology of automatic sample injection and liquid chromatography, applied in the field of automatic calibration of liquid chromatography automatic sampler and its injection port, can solve the problems of hardware damage, pollution, affecting the life of the sealing ring, etc., and improve the reliability of the instrument , The effect of reducing production costs and reducing sample residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

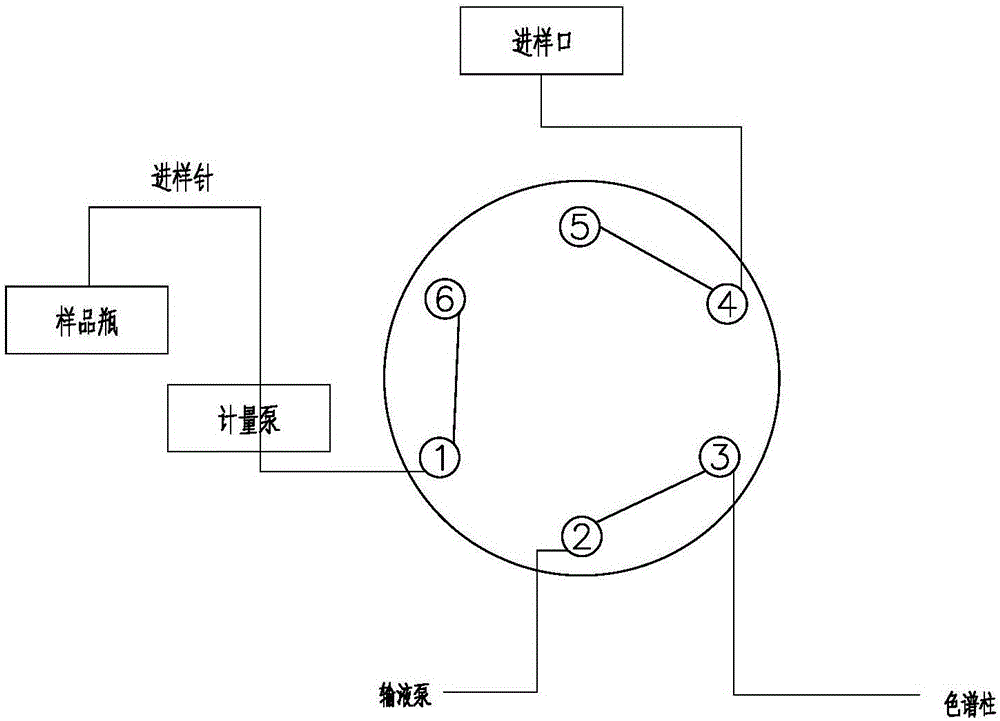

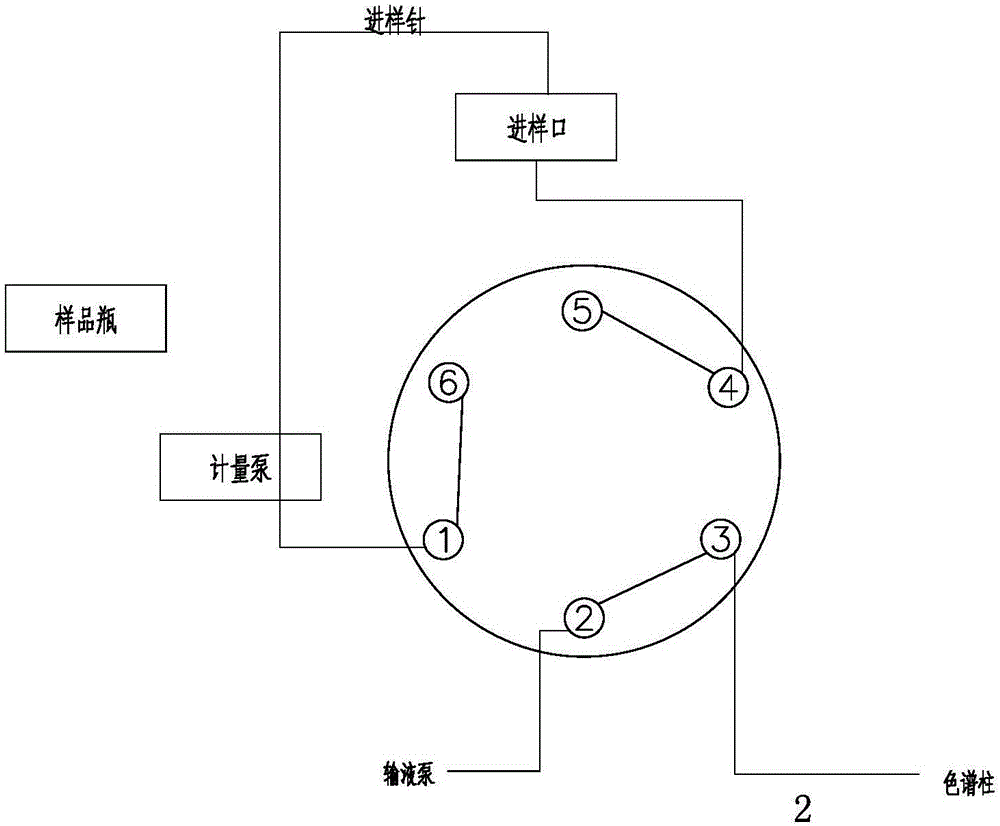

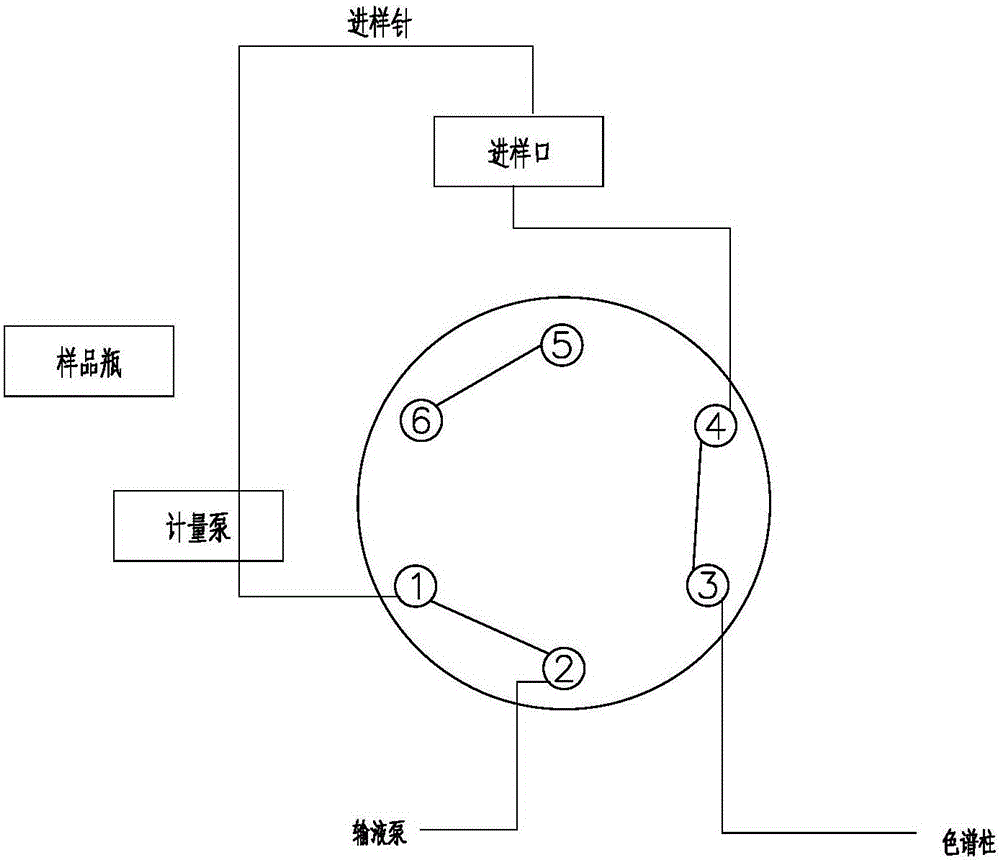

[0036] The following are specific embodiments of the present invention and in conjunction with the attached Figure 4-8 , The technical scheme of the present invention is further described, but the present invention is not limited to these embodiments.

[0037] A liquid chromatography autosampler, comprising a sample inlet, the sample inlet includes a sample injection platform 10, on the sample injection platform 10 is provided with a sealing ring seat installation groove, the sealing ring seat installation groove of the present embodiment It is T-shaped, and the sealing ring seat 20 is arranged in the sealing ring seat installation groove, and the sealing ring 30 is arranged on the upper end of the sealing ring seat 20 and is fixed between the sealing ring seat 20 and the sealing ring cover 40 by the sealing ring cover 40 . And the sealing ring cover 40 is provided with a gap between the outer wall of the sealing ring seat installation groove and the inner wall of the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com