A micro-injection tube

A technology of micro-injection and main part, which is applied in the field of injection tubes, can solve the problems of low injection precision and achieve the effects of low production cost, high injection precision and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

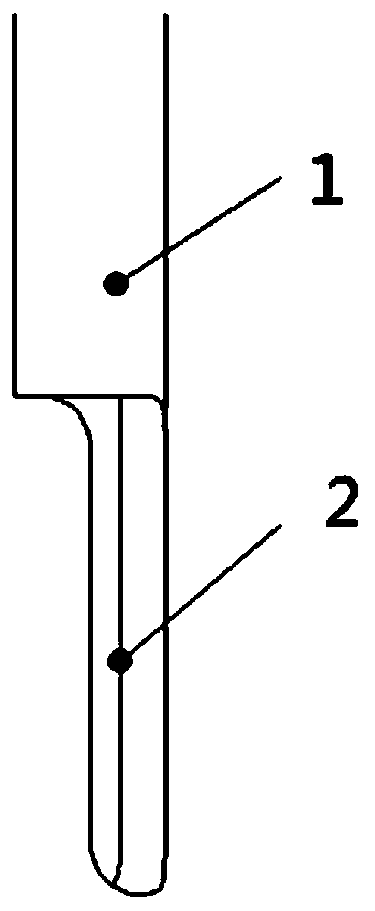

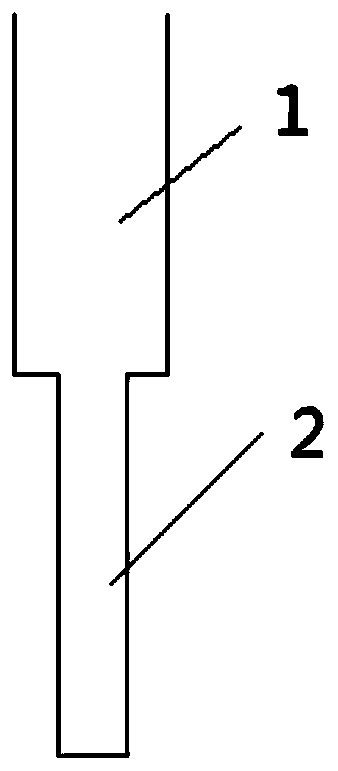

[0046]This embodiment provides a micro-injection tube, which includes a first connection part (not shown in the figure), a first body part (not shown in the figure), a second body part 1 and an immersion solution part 2. The structure of the second body part 1 and the immersion solution part 2 is as follows figure 1 , figure 2 and image 3 shown. The immersion solution part 2 is formed by extending the 1 / 4 pipe wall of the main body part, and the length of the immersion solution part 2 is 20mm. The main body part 1 is a hollow cylinder, Figure 4 is a cross-sectional schematic diagram of the main body part 1, its inner diameter is 4 mm, and its outer diameter is 7 mm. The end surface of the bottom end of the main body part 1 and the longitudinal section of the part immersed in the solution 2 are perpendicular to each other.

[0047] The first connecting portion is threadedly connected with the bottom end of the first body portion and the top end of the second body porti...

Embodiment 2

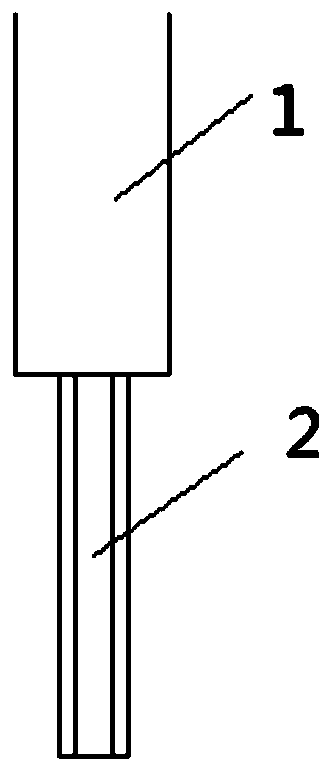

[0051] This embodiment provides a micro-injection tube, the structure of the micro-injection tube is as follows: Figure 6 As shown, it includes a main body part 1' and an immersion solution part 2'. The solution-immersed portion 2' is a cylinder having a diameter of 1.5 mm and a length of 20 mm. The main body 1' is a hollow cylinder with an inner diameter of 4 mm and an outer diameter of 7 mm. Such as Figure 6 As shown, the end surface of the bottom end of the main body part 1' is perpendicular to the longitudinal section of the immersed solution part 2'. Figure 7 It is a partial sectional view of the sampling tube of the present embodiment, as Figure 7 As shown, since the axis of the immersion solution part 2' in this embodiment is collinear with the center line of the pipe wall (the part between the inner wall and the outer wall) of the main part 1', the inner wall and the outer wall of the main part 1' are respectively aligned with The outer surfaces of the part imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com