Filling syringe for battery and battery injector therewith

A liquid injection device and liquid injection needle technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of unfavorable liquid injection volume accuracy, inaccurate liquid injection volume, and low liquid injection efficiency, etc. Simple, improve the accuracy of liquid injection, and facilitate the effect of precise liquid injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

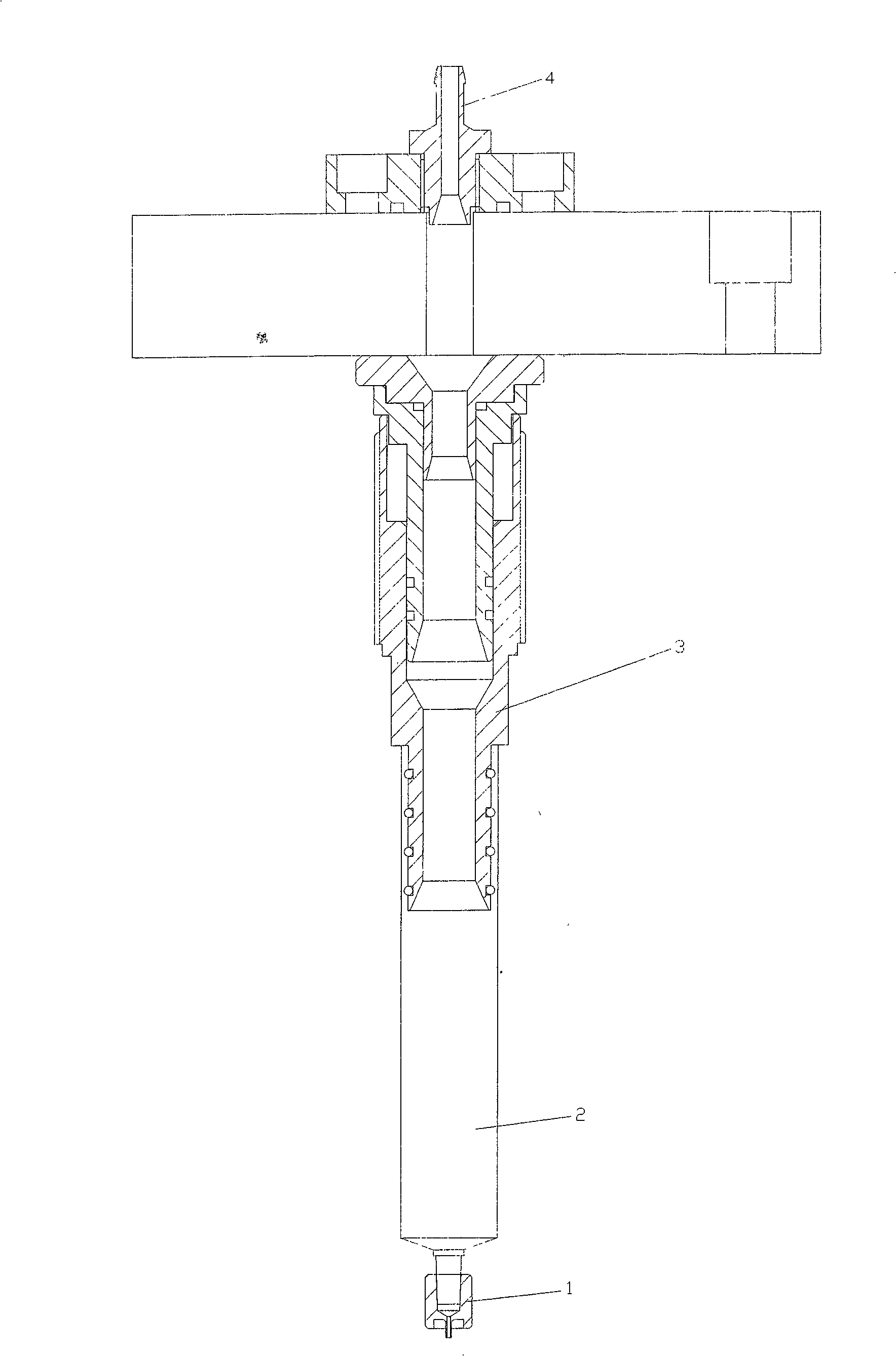

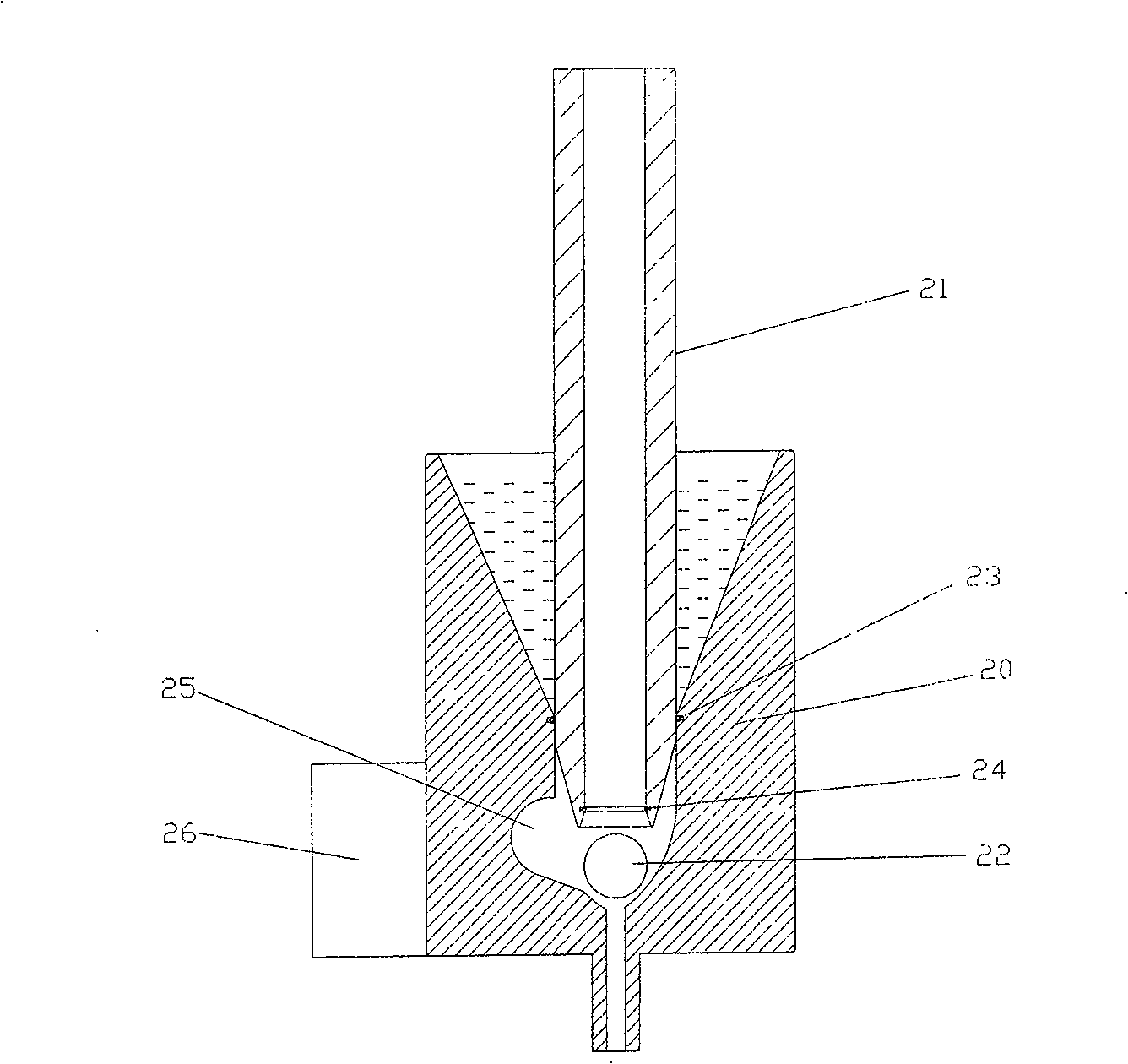

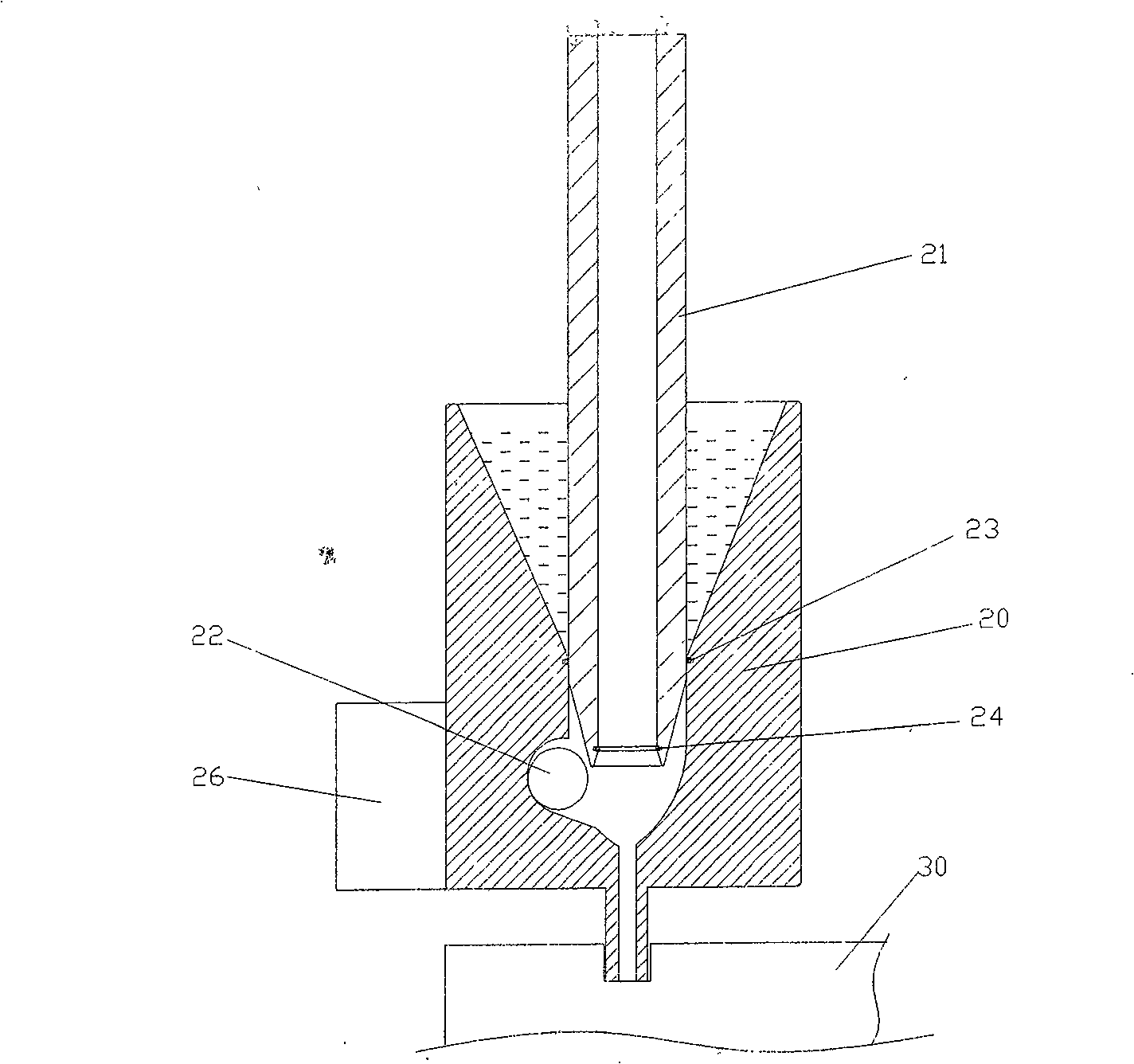

[0018] The battery liquid injection machine of the present invention has a vacuum mechanism and a liquid injection mechanism, wherein the vacuum mechanism has a vacuum suction needle, and the liquid injection mechanism has a liquid injection needle. see figure 2 As shown, it is a preferred embodiment of the battery liquid injection needle in the present invention. The battery liquid injection needle has a needle head 20, and the needle head 20 is provided with a substantially funnel-shaped inner cavity. A hollow tubular vacuum suction needle 21 is inserted into the inner cavity of the needle 20, and tightly fits with the inner cavity neck of the needle 20, and a sealing ring 23 is arranged on the inner cavity neck in contact with it. A steel ball 22 is arranged in the inner cavity of the needle 20, the diameter of which is larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com