Battery electrolyte injection cup

A liquid injection cup and battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high corrosion risk of electrolyte, limit battery production efficiency, human and environmental damage, etc., to save manpower and material resources, The effect of reducing residual amount and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the present invention, and the drawings are only for the purpose of illustration and are not drawn according to the original size.

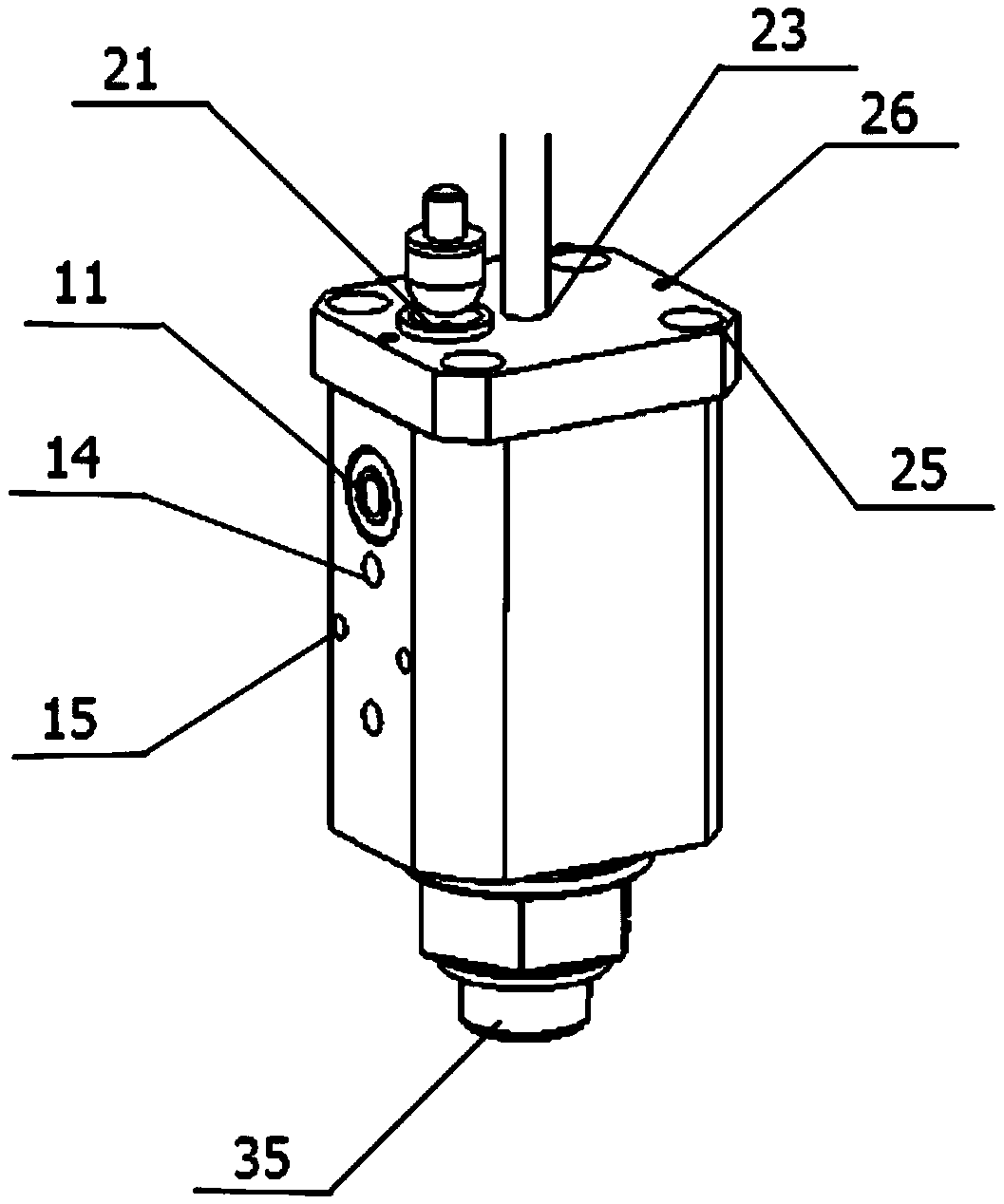

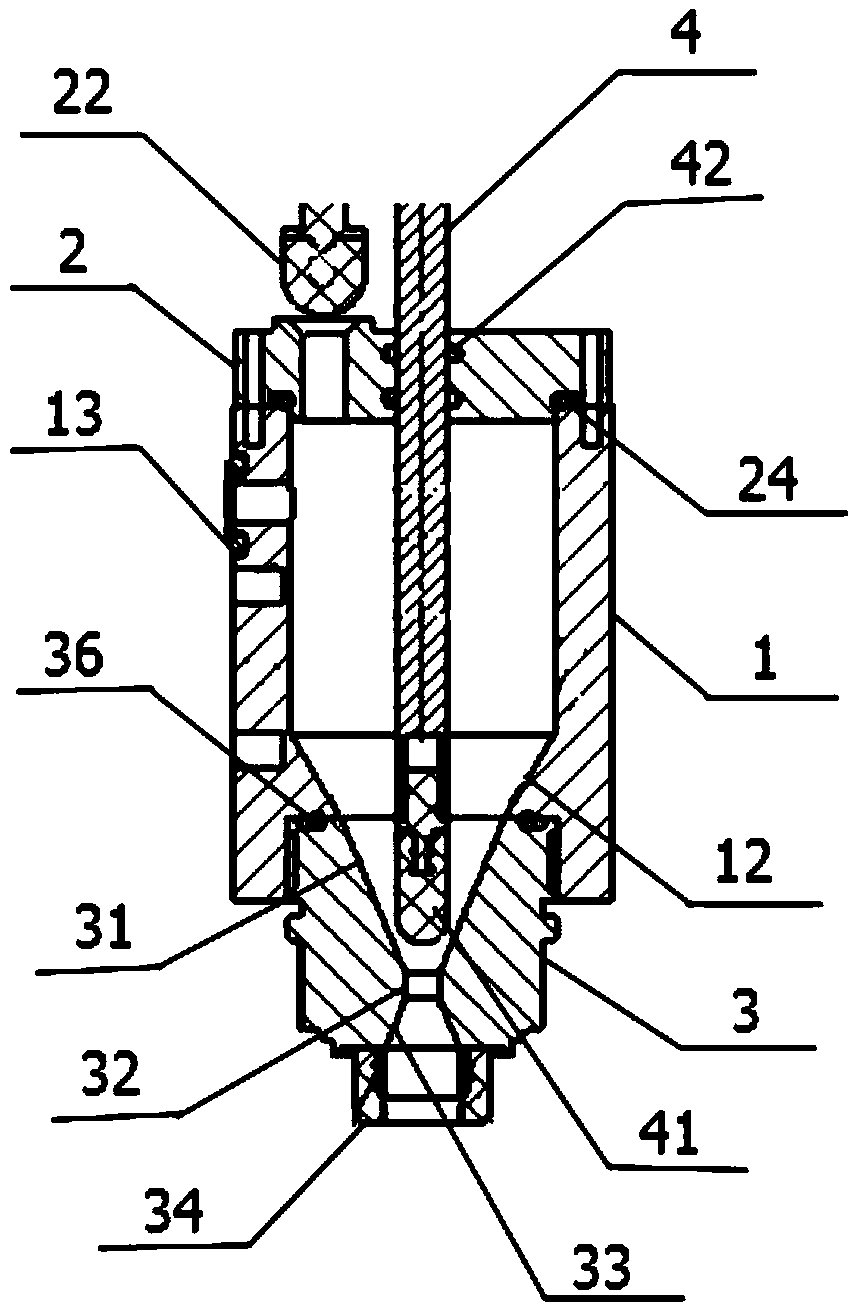

[0024] like figure 1 , figure 2 As shown, this embodiment provides a battery liquid injection cup, including a cup cover 2, a cup body 1 and a liquid injection nozzle 3, wherein the cup cover 2 is fixed on the top of the cup body 1 by bolts, and the liquid injection nozzle 3 is fastened by tightening The parts are fixed to the bottom of the lid body 1 . The cup cover 1 is provided with a liquid inlet 21 for injecting elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com