Battery liquid-filling device

A liquid injection device and battery technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems affecting the time and degree of liquid injection, high production costs, and the volume of the drying box is unfavorable for large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

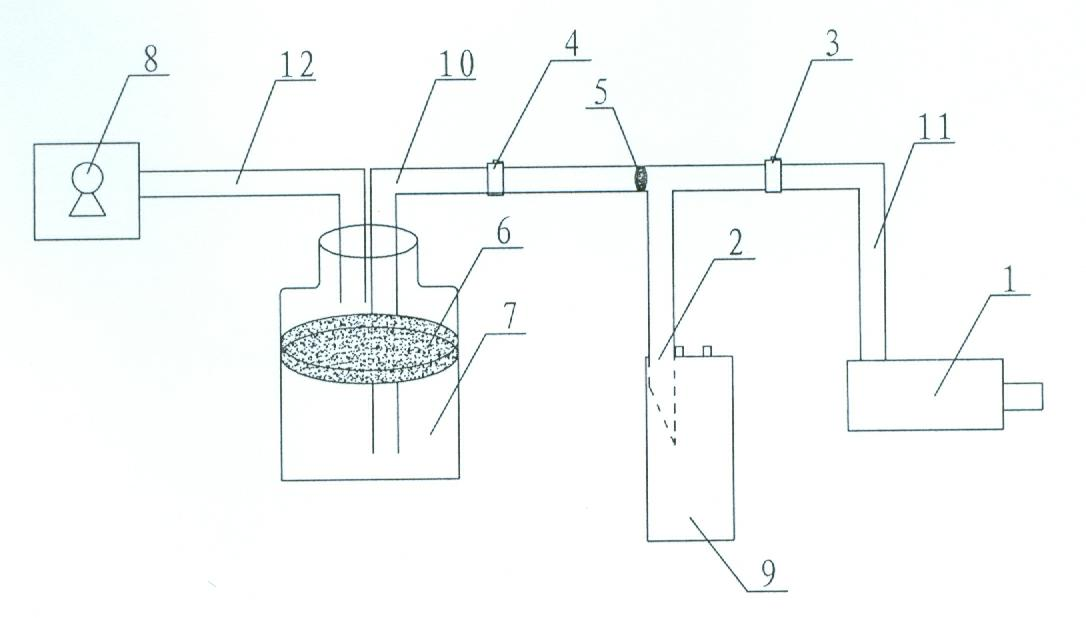

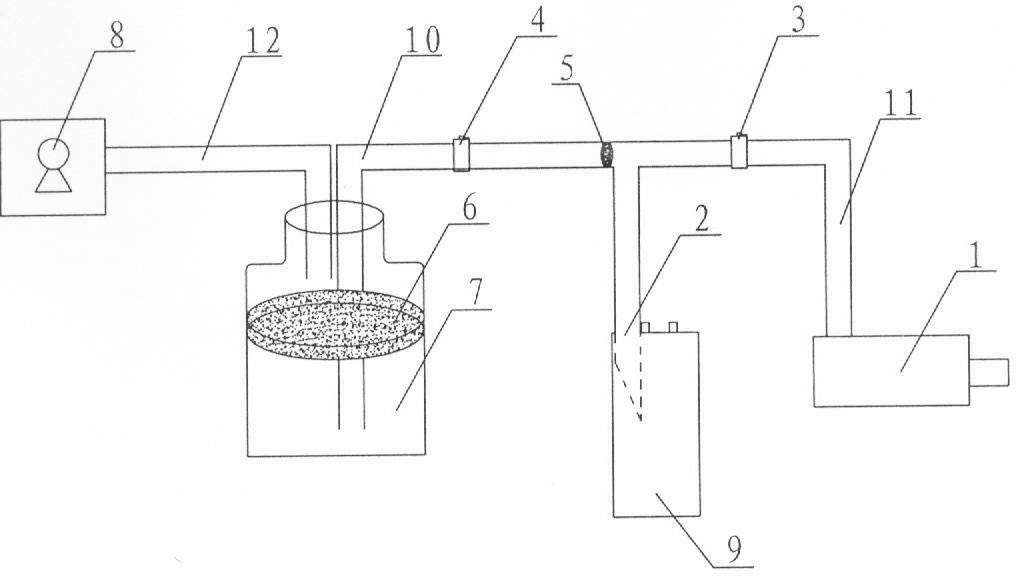

[0010] Referring to the accompanying drawings, the air suction pump 8, the suction pipe 12, the buffer bottle 7, the air suction pipe 10, the liquid injection pipe 11, and the precision metering pump 1 are sequentially sealed and connected. There are suction electromagnetic valve 4 and filter sheet 5, and there is a secondary filter sheet 6 at the mouth of the buffer bottle. Prepare the battery electrolyte that needs to be used and the battery 9 that needs to be injected. After connecting the battery electrolyte to the precision metering pump 1, insert the liquid injection pipe 11 into the battery liquid injection hole, and seal it with the sealing ring 2. The material is PP, close the liquid inlet solenoid valve 3, open the suction solenoid valve 4, turn on the suction pump 8, and pump the battery 9 that needs liquid injection through the suction pipe 12 and the suction pipe 10 to form a negative pressure in the battery 9 , close the suction solenoid valve 4, turn on the prec...

Embodiment 2

[0012] In this example, the material of the filter is polypropylene, the pore size is 30 μm, and the porosity is 70%, the material of the liquid injection tube is stainless steel, and the rest are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com