Digital quantitative continuous injection pump

A liquid injection pump and digital technology, which is applied in the fields of cleaning instruments, liquid injection and sample injection, can solve the problems of non-constant flow rate pump, slow peristaltic pump flow rate, and low liquid injection precision, so as to achieve a wide range of applications and prevent cavitation. , The effect of high injection precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

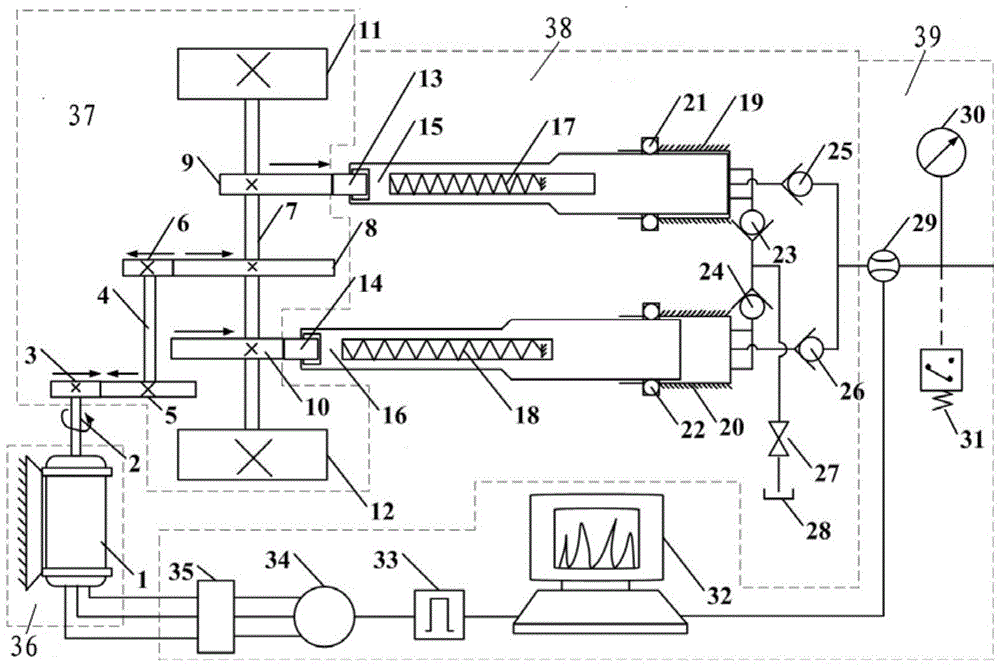

[0036] Such as figure 1 As shown, the digital quantitative continuous injection pump includes a power source 36, a transmission system 37, an actuator 38, and a control system 39. The power source 36 outputs rotational motion, and the transmission system 37 changes the speed of the rotational motion output by the power source, and then It is converted into a linear motion, and then drives the actuator 38 to suck the liquid in the container 28 into the device, and then discharge it from the liquid outlet. The control system 39 is used to control the entire device, and realize stepless speed change by controlling the pulse frequency. Realize by controlling the number of pulses Quantitative liquid injection, improve the accuracy of liquid injection by introducing flow feedback, and realize overload protection by introducing pressure switch.

[0037] Further, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com