An automatic sizing device for steel bars

A steel and automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the accuracy and service life of CNC equipment, increasing the difficulty and cost of use, and high cost of CNC equipment, so as to achieve low cost and automation The effect of high degree and strong continuous working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

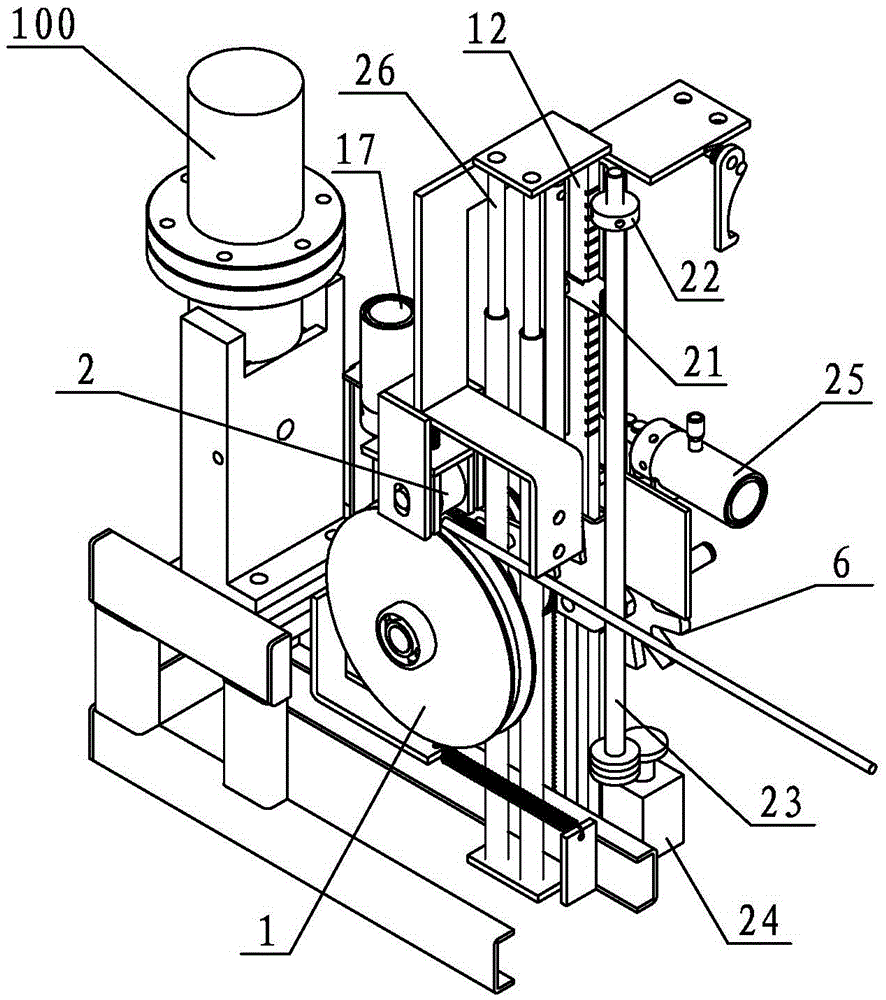

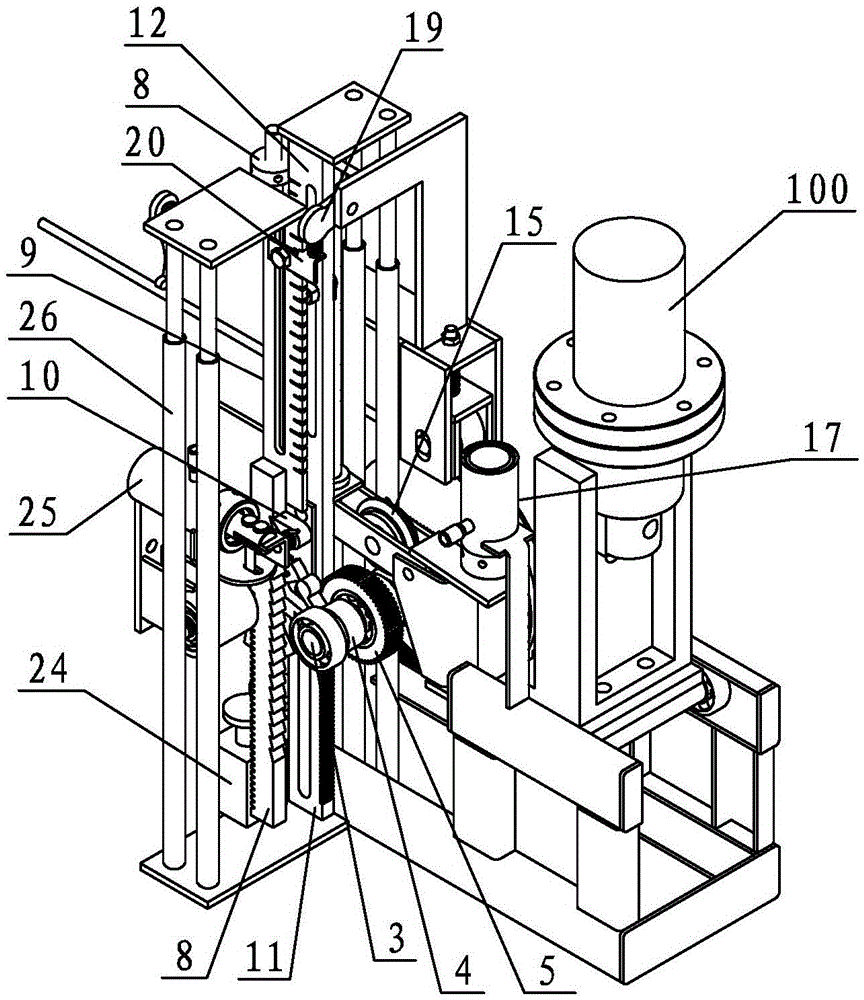

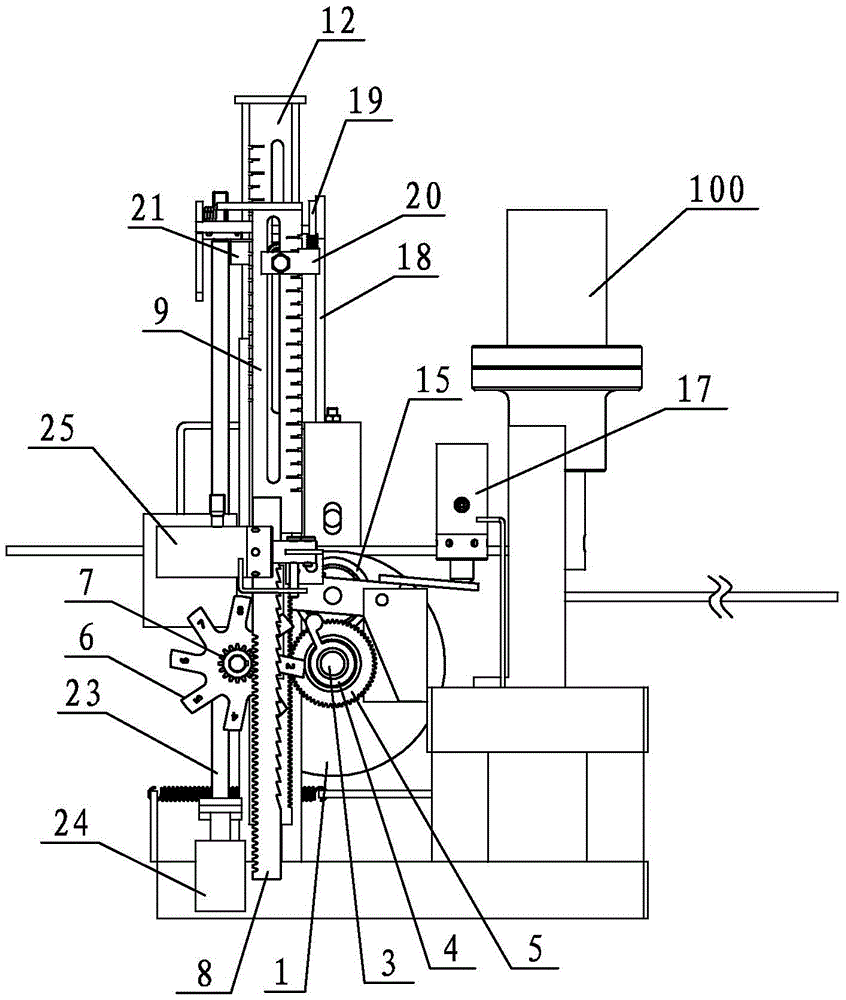

[0031] The automatic steel bar measuring and scaling device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] refer to Figure 1 to Figure 4 , the preferred embodiment that the present invention provides, described measuring and sizing device comprises the circumference ruler wire wheel 1 of real-time measurement steel bar moving distance, the number of weeks measuring mechanism that is used to measure the circumference ruler wire wheel rotation cycle number and is used to measure the circumference ruler line Decimal measuring mechanism for the distance turned by the wheel.

[0033] Described week ruler line wheel 1 is arranged close to the steel bar, and week ruler line wheel 1 top is provided with pinch wheel 2, and pinch wheel 2 is pressed on the steel bar on week ruler line wheel 1, prevents that reinforcing bar from getting loose from week ruler line wheel 1, When steel bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com