Compound fruit and vegetable cleaning device

A fruit and vegetable cleaning and composite technology, applied in application, food processing, climate change adaptation, etc., can solve problems such as unsuitable continuous large-scale cleaning operation, water catalyst can not work normally, and can not achieve the desired effect, etc., to achieve good disinfection and purification effect , easy to collect and recycle, and occupy a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

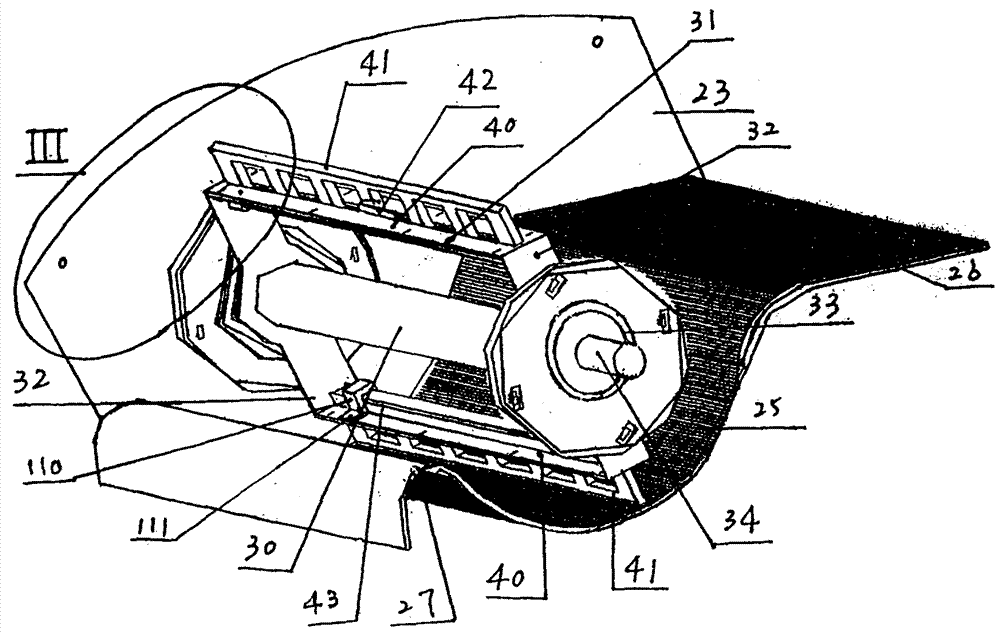

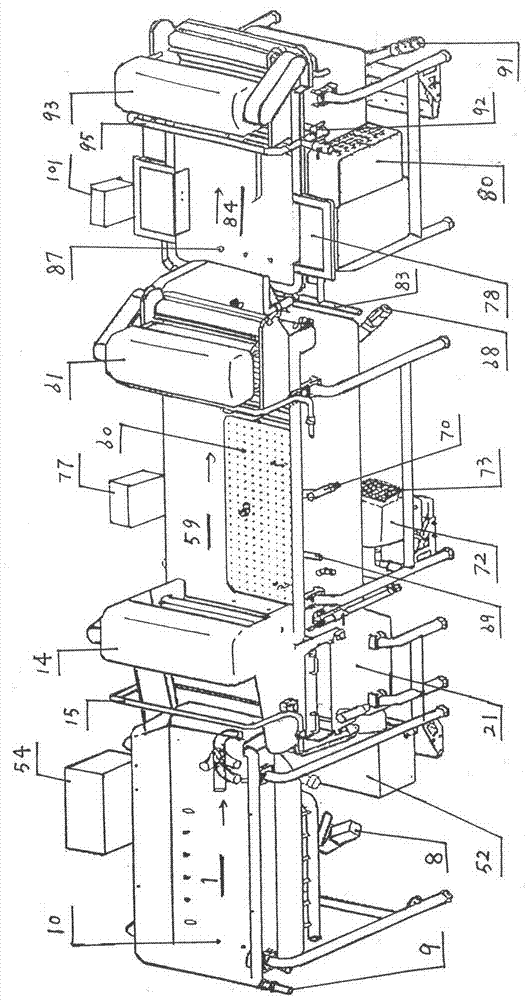

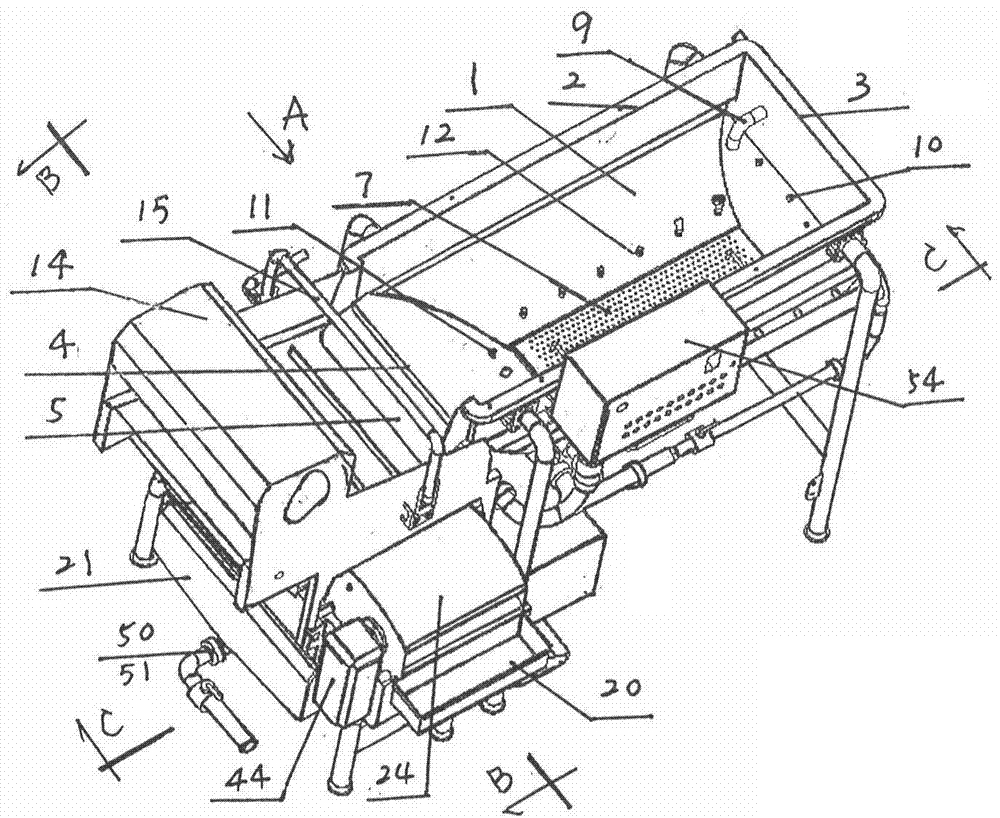

[0036] Further detailed description in conjunction with the accompanying drawings; the arrows in the figure show the direction of water or air flow;

[0037] Such as figure 1As shown, the composite fruit and vegetable cleaning device is composed of a first-level water-washing rough washing machine, a second-level bubble-type fine washing machine, and a third-level water catalyst disinfection and purification machine, and each level has a corresponding rack, water tank, and water circulation system. And the matching conveyor belt components; between the first and second levels, and between the second and third levels are connected together through the supporting No. 1 and No. 2 conveyor belt components respectively, and the upper level is automatically conveyed to the next level. , until the third level is collected; the first, second and third level electric control panels are respectively installed on the racks of each level, or installed in a centralized manner, and the over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com