Vibration grinding and polishing machine capable of sorting automatically

A polishing machine, vibration motor technology, applied in surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc. It can improve the grinding efficiency, simple structure and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

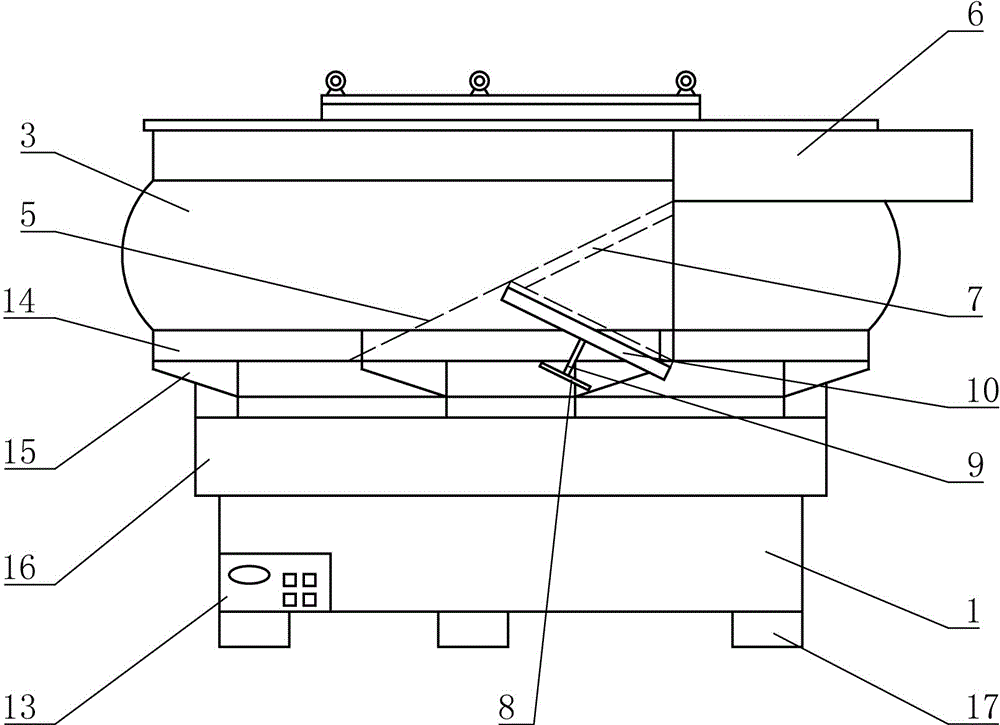

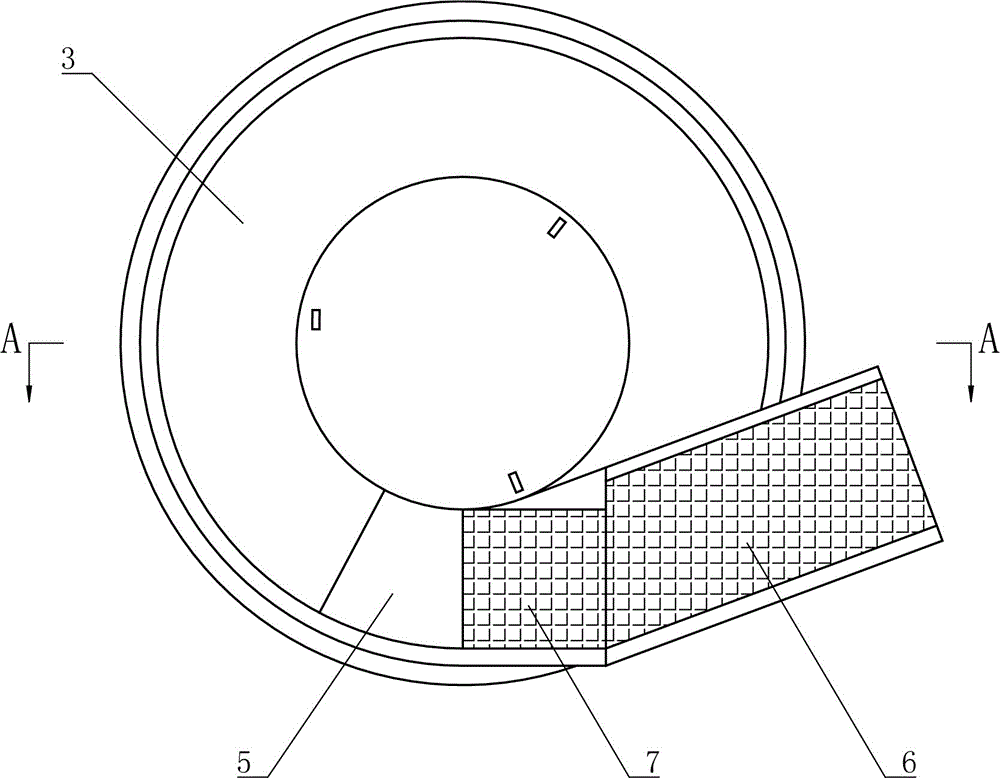

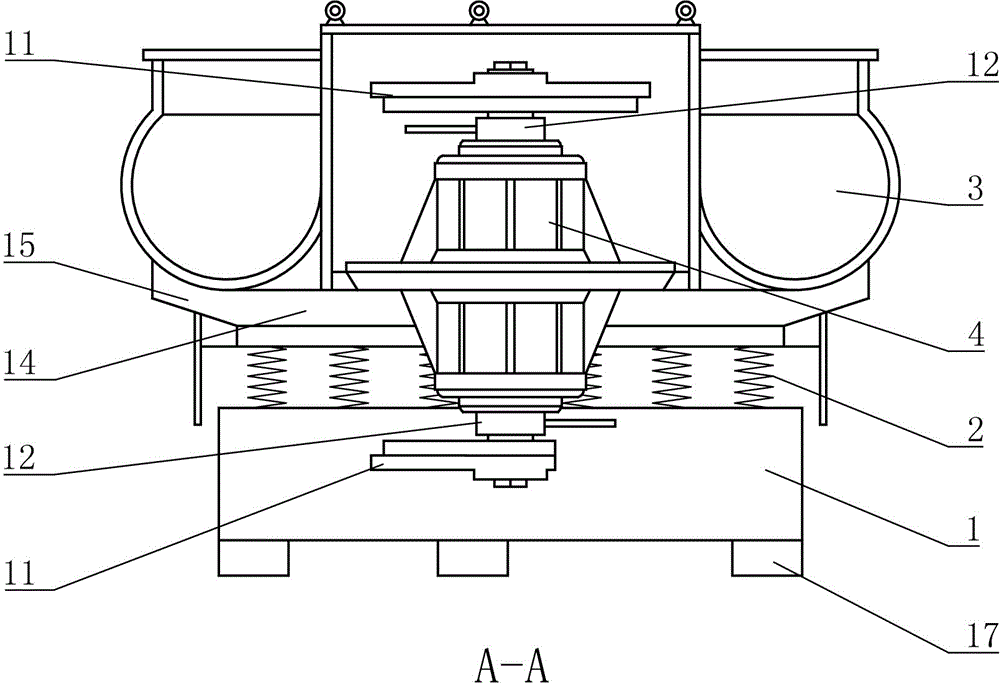

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] The vibration grinding and polishing machine of automatic material selection of the present invention, as figure 1 and image 3 As shown, it includes a base 1, a vibrating plate 3 provided by a spring 2 on the base 1, and a vibrating motor 4 fixedly arranged in the center of the vibrating plate 3; the vertical section above the outer side wall of the vibrating plate 3 and the inner side wall are vertical, and the outer side wall The longitudinal section of the lower part and the bottom are connected in an arc shape, and the interior space is large, while the opening of the upper part is narrowed, which is conducive to the spiral movement and inward turning movement of the workpiece and the abrasive; the bottom is provided with a triangular longitudinal section. 5. The movement range of the workpiece and the abrasive in the up and down direction is intensified, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com