A periodic quantitative counting device

A technology of counting device and number of weeks, which is applied in the direction of counting mechanism/items, instruments, etc., can solve the problems of high cost, difficult maintenance and easy failure of numerical control instruments, and achieve the effect of strong continuous working ability, convenient use and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

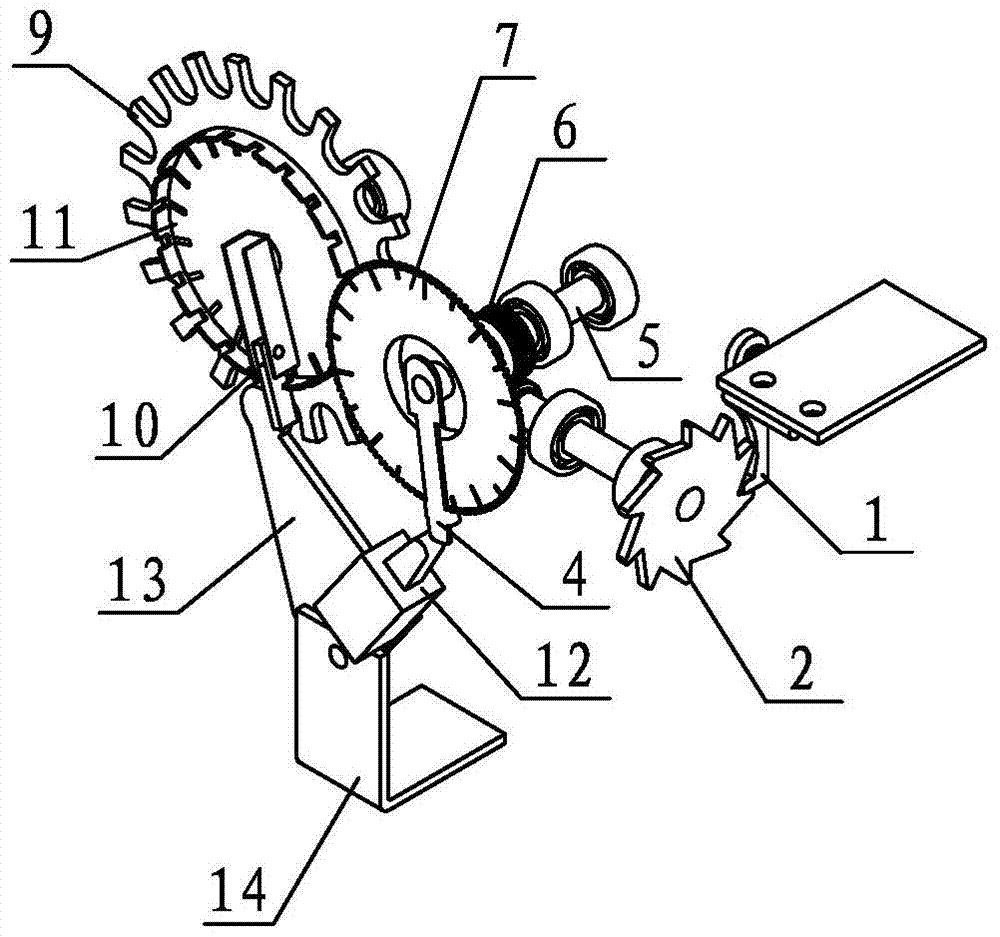

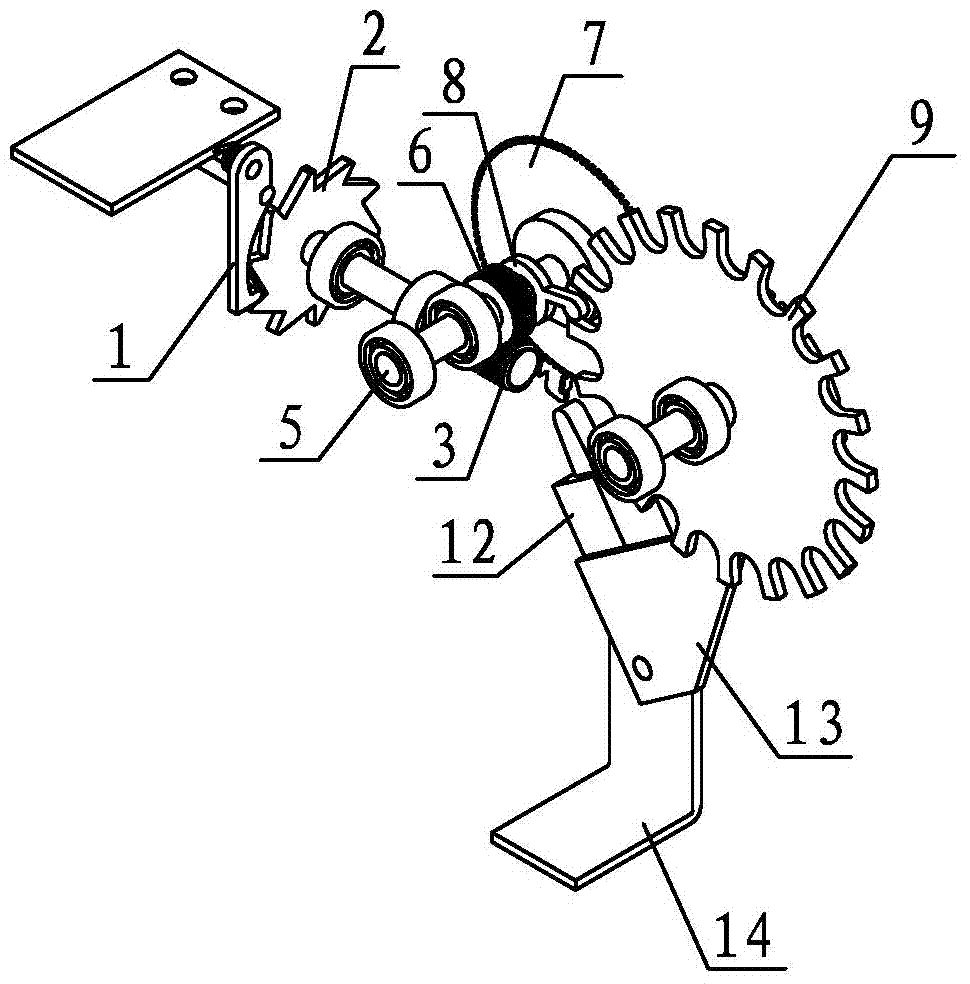

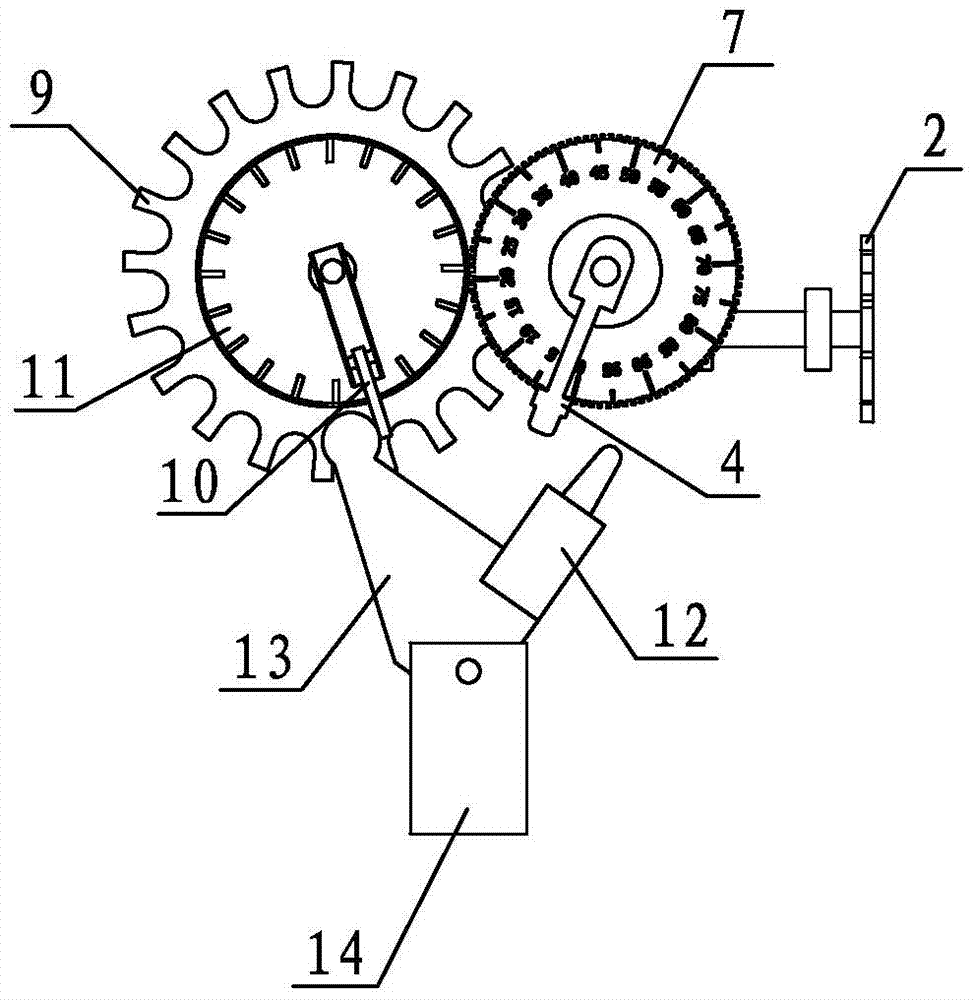

[0026] The periodic quantitative counting device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] refer to figure 1 , figure 2 , a preferred embodiment provided by the present invention—period quantitative counting device applied to the measurement of the number of steel bars, including a shift block 1, a one-way dial 2, a number recorder, a cycle number recorder and a travel switch 12.

[0028] The dial block 1 is used to toggle the one-way dial 2 for counting. The dial block 1 can be linked with the cutting device, the measuring device or the bending device, etc., refer to Figure 5 , is a structural diagram of the combined use of the periodic quantitative counting device 100, the measuring and sizing device 200, and the cutting device 300 in this embodiment, wherein the shift block 1 is linked with the measuring and sizing device 200, when the measuring and sizing device 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com