Sewage purification device for environmental protection

A technology for sewage purification and environmental protection, applied in chemical instruments and methods, filtration and separation, fixed filter element filters, etc., can solve the problems of complex structure, low flexibility of use, poor continuity of sewage filtration, etc., and achieve continuous working ability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

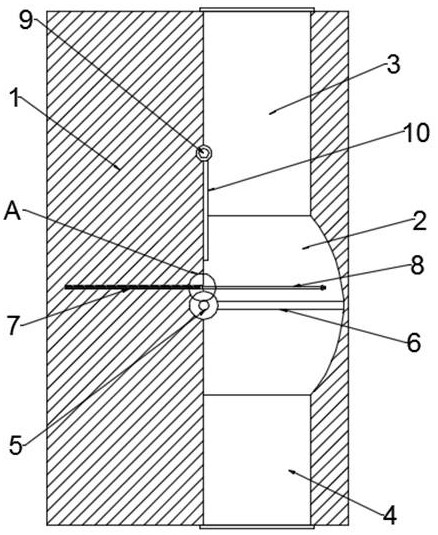

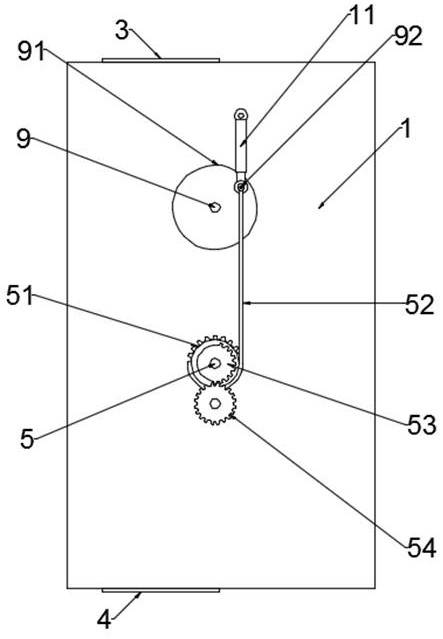

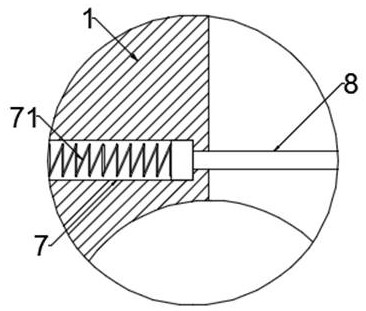

[0022] see figure 1 , 2 And 5, in the embodiment of the present invention, a sewage purification device for environmental protection, including a housing 1, a filter passage is provided through the housing 1, and a first rotating shaft 5 is rotatably connected to the filter passage for Filter screen plate 6 for filtering, one side of the filter screen plate 6 is fitted with a self-cleaning mechanism telescopically fitted on the filter channel, and the self-cleaning mechanism is located in the filter channel and is rotated and connected to the side away from the filter screen plate 6 There is a second rotating shaft 9, and the periphery of the second rotating shaft 9 is fixedly connected with a water baffle 10 matching with the filter channel, and the first rotating shaft 5 and the second rotating shaft 9 alternately rotate through a linkage mechanism.

[0023] In this embodiment, preferably, the water can flow through the filter screen plate 6 to complete the filtration. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com