All-solid waste fiber reinforced geopolymer composite material suitable for 3D printing technology

A 3D printing and geopolymer technology, applied in the direction of additive processing, cement production, etc., can solve the problems of high cost and unfavorable application of nano-graphene, and achieve the effect of improving sustainability, considerable ductility, and dense and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] According to the number of parts by mass, raw materials are weighed: 25 parts of aggregate, 75 parts of cementitious material (in terms of mass fraction, 30% of fly ash, 60% of slag, 10% of silica fume), PVA fiber (2% of volumetric dosage) ), carbon nanotubes (2% of aggregate and cementitious material gross mass), alkali activator (add 650mL alkali activator in the mixture of every kilogram aggregate and cementitious material);

[0049] Wherein the preparation method of the alkali activator: dissolve the NaOH solid in deionized water in proportion to prepare a 6mol / L sodium hydroxide solution, place it at room temperature for 24 hours until the solution is cooled to room temperature, add an aqueous solution of sodium silicate in a mass ratio of 3:7 ( Na 2 O nSiO 2 , n=1.5), stir evenly to obtain alkali activation solution for subsequent use;

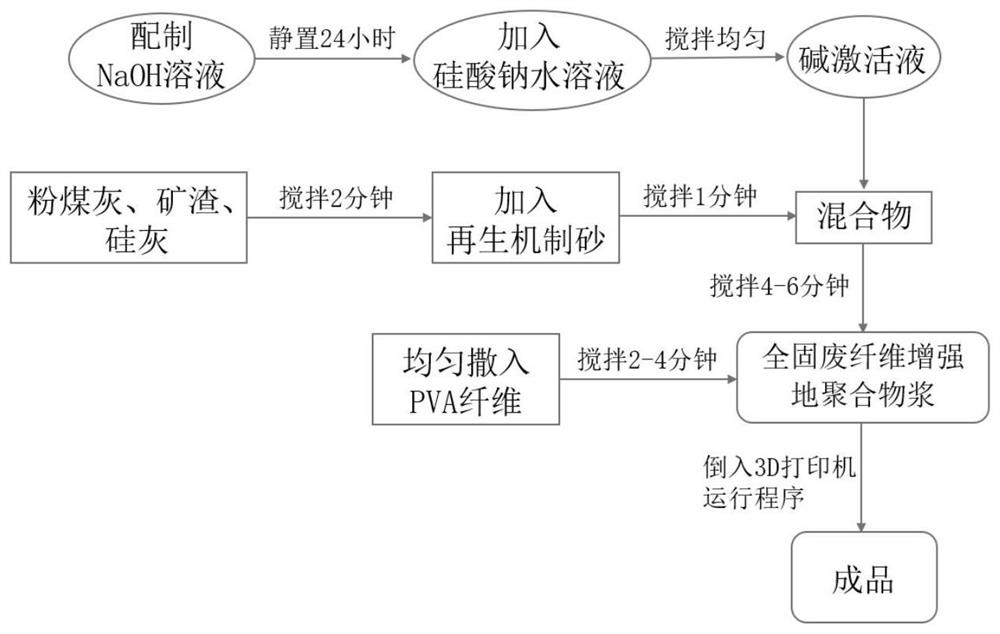

[0050] The preparation method is as follows ( figure 2 Schematic flow chart for the preparation of concrete composite materi...

Embodiment 2

[0055] With embodiment 1, the difference is that according to the number of parts by mass, raw materials are weighed: 25 parts of aggregate, 75 parts of cementitious material (in terms of mass fraction, fly ash 30%, slag 60%, silica fume 10%), PVA Fiber (2% of volume dosage), carbon nanotube (2% of aggregate and cementitious material total mass), alkali activator (add 650mL alkali activator in the mixture of every kilogram of aggregate and cementitious material);

[0056] Wherein the alkali activator preparation method: NaOH solid is dissolved in deionized water in proportion to prepare the sodium hydroxide solution of 8mol / L, place at room temperature for 24 hours until the solution is cooled to room temperature, add sodium silicate aqueous solution by 3:7 mass ratio ( Na 2 O nSiO 2 , n=1.5), and stir evenly to obtain an alkali activation solution for later use. The initial setting time of the slurry was determined to be 10 minutes; the compressive strength of the product d...

Embodiment 3

[0058] With embodiment 1, the difference is that according to the number of parts by mass, raw materials are weighed: 25 parts of aggregate, 75 parts of cementitious material (in terms of mass fraction, fly ash 30%, slag 60%, silica fume 10%), PVA Fiber (2% of volume dosage), carbon nanotube (2% of aggregate and cementitious material total mass), alkali activator (add 650mL alkali activator in the mixture of every kilogram of aggregate and cementitious material);

[0059] Wherein the preparation method of the alkali activator: the NaOH solid is dissolved in deionized water in proportion to prepare a 10mol / L sodium hydroxide solution, placed at room temperature for 24 hours until the solution is cooled to room temperature, and added in a 3:7 mass ratio of sodium silicate aqueous solution ( Na 2 O nSiO 2 , n=1.5), and stir evenly to obtain an alkali activation solution for later use. The initial setting time of the slurry was determined to be 10 minutes; after 28 days of natur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com