Low temperature methanol wash method and equipment

A low-temperature methanol washing and methanol technology, which is applied in the purification, treatment and recovery of natural gas and other carbonyl gases, and the field of coal-to-gas, can solve problems such as only 98%, and achieve the effect of reducing equipment power consumption and increasing recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

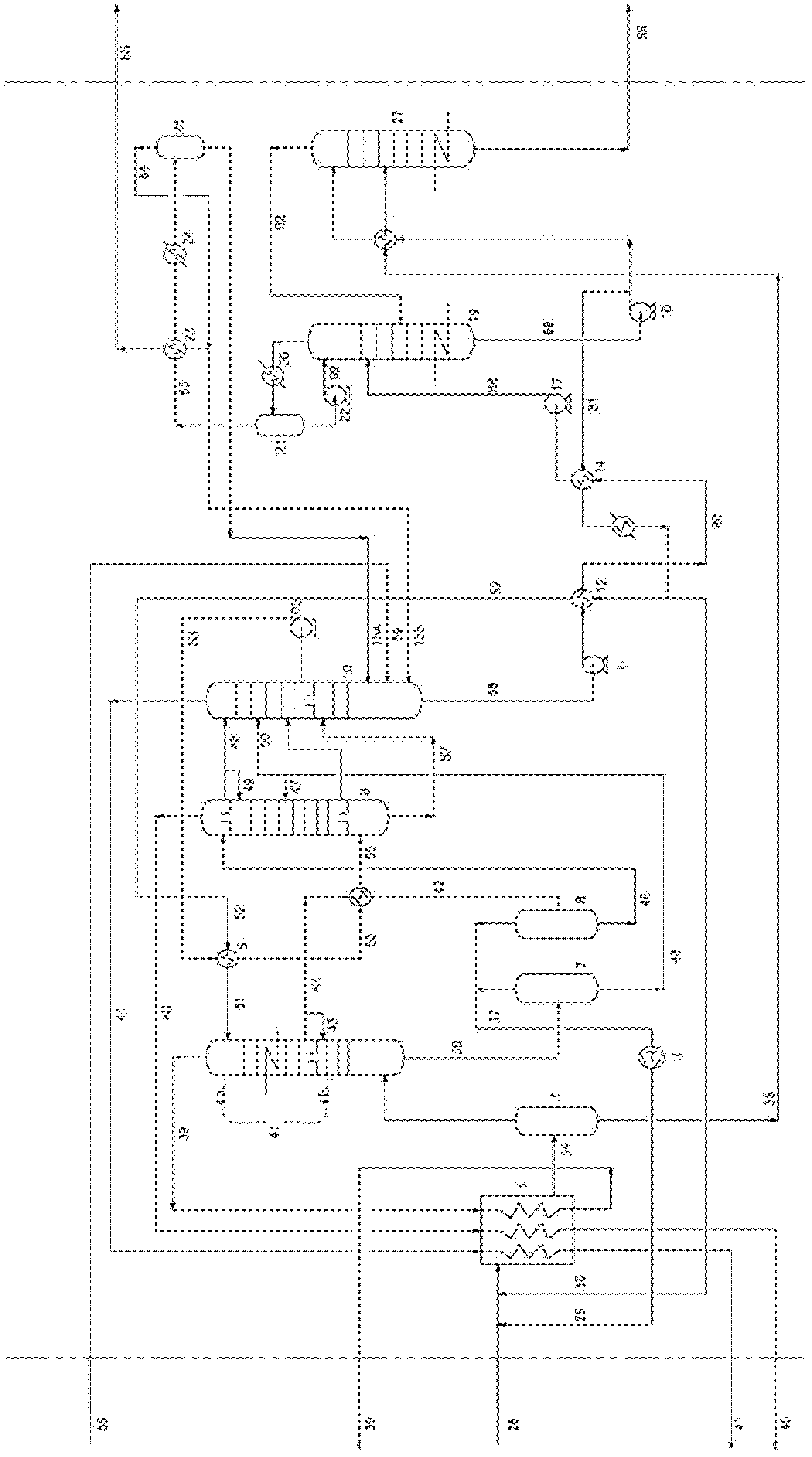

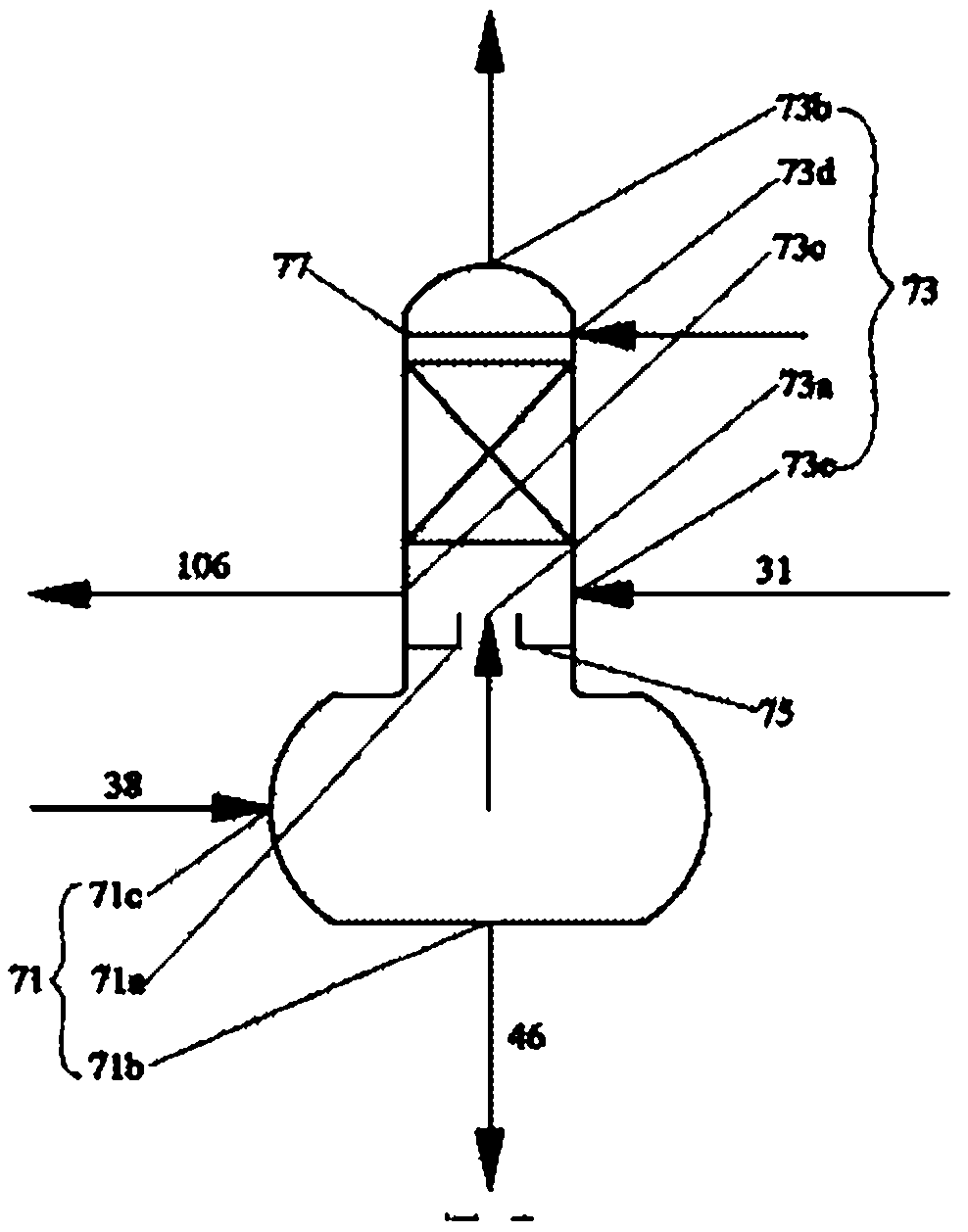

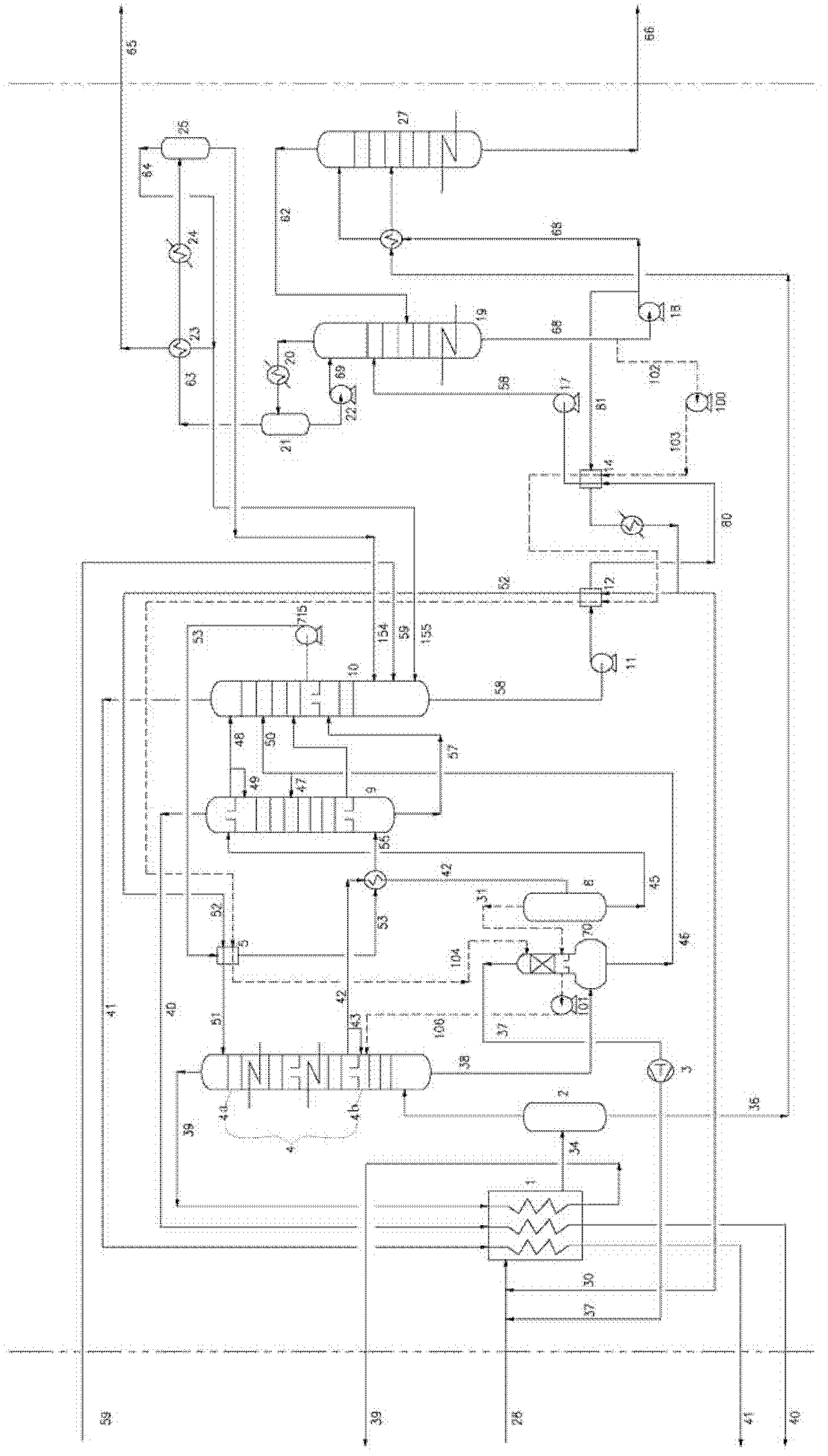

[0073] Preparation method: the following combined with figure 2 with 3 , the low-temperature methanol washing method of the present invention is further described:

[0074] The first lean methanol solution 30 is combined with the spray methanol 30 and the circulating gas 29 for the first absorption to form a gas-liquid mixture. The gas-liquid mixture is cooled to about -12.0°C by the feed gas cooler 1 to form the first rich The methanol solution 34, the first methanol-rich solution 34 enters the gas-liquid separator 2, and after separation and dehydration, a first gas and a first liquid 36 are generated. The first liquid 36 passes through the methanol-water separation tower 27 to remove water and generate methanol vapor for recovery. The first gas enters the methanol washing tower 4, and uses the second lean methanol solution 51 flowing down from the top of the tower to complete the decarburization treatment in the upper decarburization section of the tower to generate a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com